Assembly / adjustment, Drive axle overhaul – Spicer Drive Axles Service Manual Single Axles 2-Speed & Double Reduction User Manual

Page 24

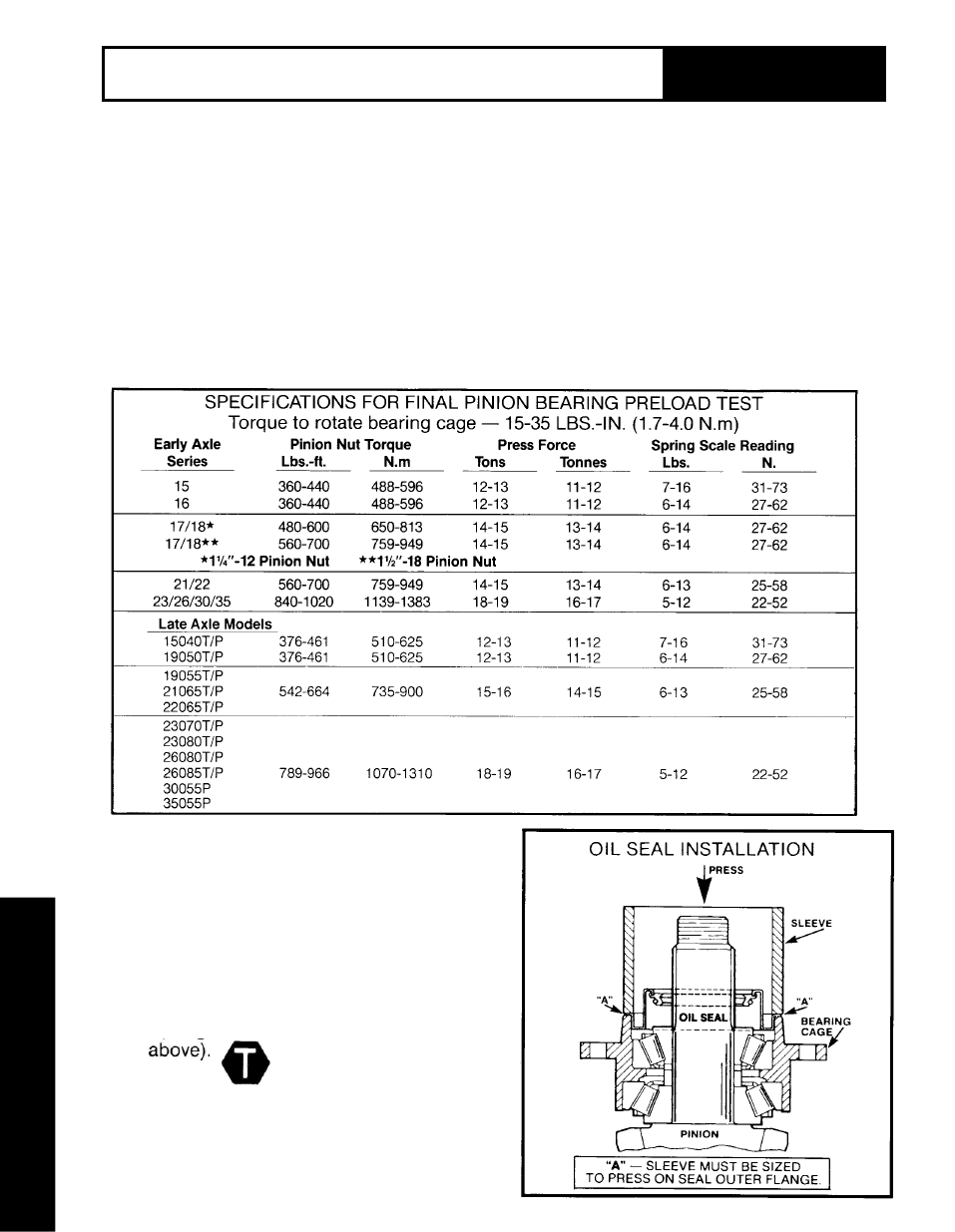

Final Pinion Bearing Preload Test

(cont'd)

2. Measure Pinion Bearing Preload - Use a

spring scale to test the assembly rolling

torque. To use the spring scale, wrap soft

wire around the bearing cage, attach the

scale and pull. Preload is correct when

torque required to rotate the pinion bearing

cage is from 15 to 35 LBS.-IN. (1.7-4.0 N.m).

This specification is translated into spring

scale readings in the chart below.

3. Adjust Pinion Bearing Preload - If

necessary, adjust pinion bearing preload.

Disassemble the pinion bearing cage as

recommended in this manual and change

the pinion bearing spacer. A thicker spacer

will decrease preload. A thinner spacer will

increase preload.

IMPORTANT: Use the correctly sized

spacer. Do not use shim stock or grind

spacers. These practices can lead to loss of

bearing preload and gear or bearing failure.

Install Pinion Oil Seal and Yoke

1. With pinion bearing preload adjustment

complete, install oil seal. Use a press and

properly sized sleeve to prevent distortion

or contact with seal lips during installation

(see illustration).

2. Make sure yoke is clean and dry. Install

yoke and nut (or nut and washer on some

models). Tighten nut to correct torque (see

.

chart

NOTE: After tightening nut, recheck pinion

bearing rolling torque, then proceed with

pinion installation in carrier.

24

Section

3

ASSEMBLY / ADJUSTMENT

Drive Axle

Overhaul