Removal / disassembly, Drive axle overhaul – Spicer Drive Axles Service Manual Single Axles 2-Speed & Double Reduction User Manual

Page 23

Test

(cont'd)

CAUTION: Use the correctly sized

spacer. Do not use shim stock or grind

spacers. These practices can lead to loss of

bearing preload and gear or bearing failure.

5. Once correct bearing preload has been

established, note the spacer size used.

Select a spacer 0.001" larger for use in the

final pinion bearing cage assembly. The

larger spacer compensates for slight

"growth" in the bearings which occurs when

they are pressed on the pinion shank.

NOTE: With the first stage of bearing preload

adjustment ("Trial Build-Up") completed,

continue reassembly of bearing cage and

pinion.

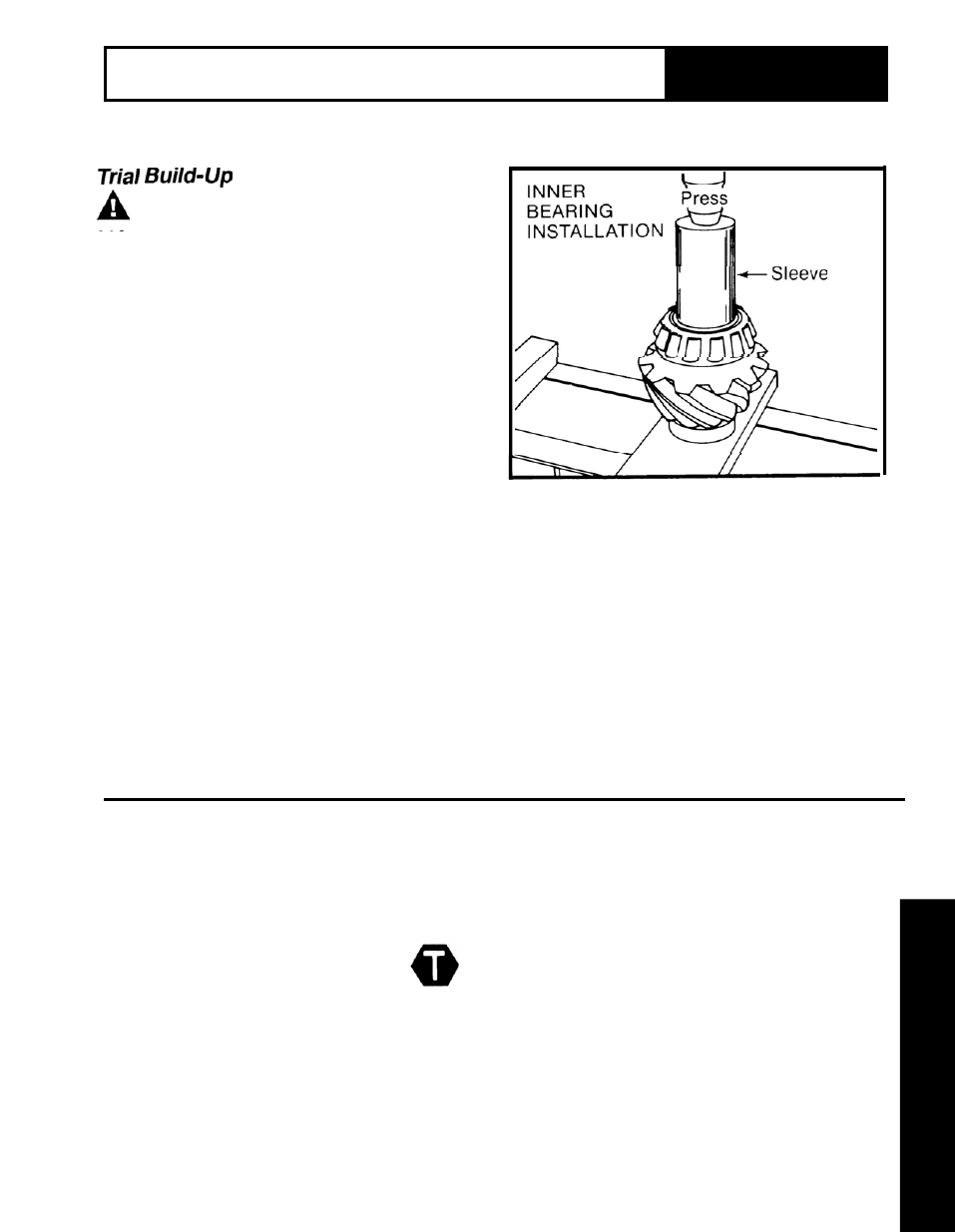

6. Press inner bearing cone on pinion using

a properly sized sleeve.

7. Install bearing spacer washer where

used. See illustration on preceding page

for applications.

8. Install bearing cage and cup assembly on

pinion. Insert outer bearing cone in cage,

then press bearing cone and cage assembly

on pinion.

I

9. At this stage of pinion reassembly,

recheck bearing preload adjustment by

performing "Final Bearing Preload Test" (see

following procedures).

Final Pinion Bearing Preload Test

1. With pinion and bearing cage assembled

PRESS METHOD: Press should be equipped

as previously described, measure bearing

with a calibrated load cell to insure proper

preload using either of the two following

clamp load. Position a sleeve so that load is

methods:

applied directly to backface of the outer

bearing cone. Apply clamp load (see chart

VISE METHOD: Install yoke and nut,

next page). Check bearing cage rolling

tightening nut to correct torque (see chart).

torque (see Step 2).

Mount the pinion assembly in a vise,

clamping yoke firmly. Apply clamp load

(see chart next page). Check bearing cage

rolling torque (see Step 2).

23

Section

3

REMOVAL / DISASSEMBLY

Drive Axle

Overhaul