Adjustment, Drive axle overhaul – Spicer Drive Axles Service Manual Single Axles 2-Speed & Double Reduction User Manual

Page 28

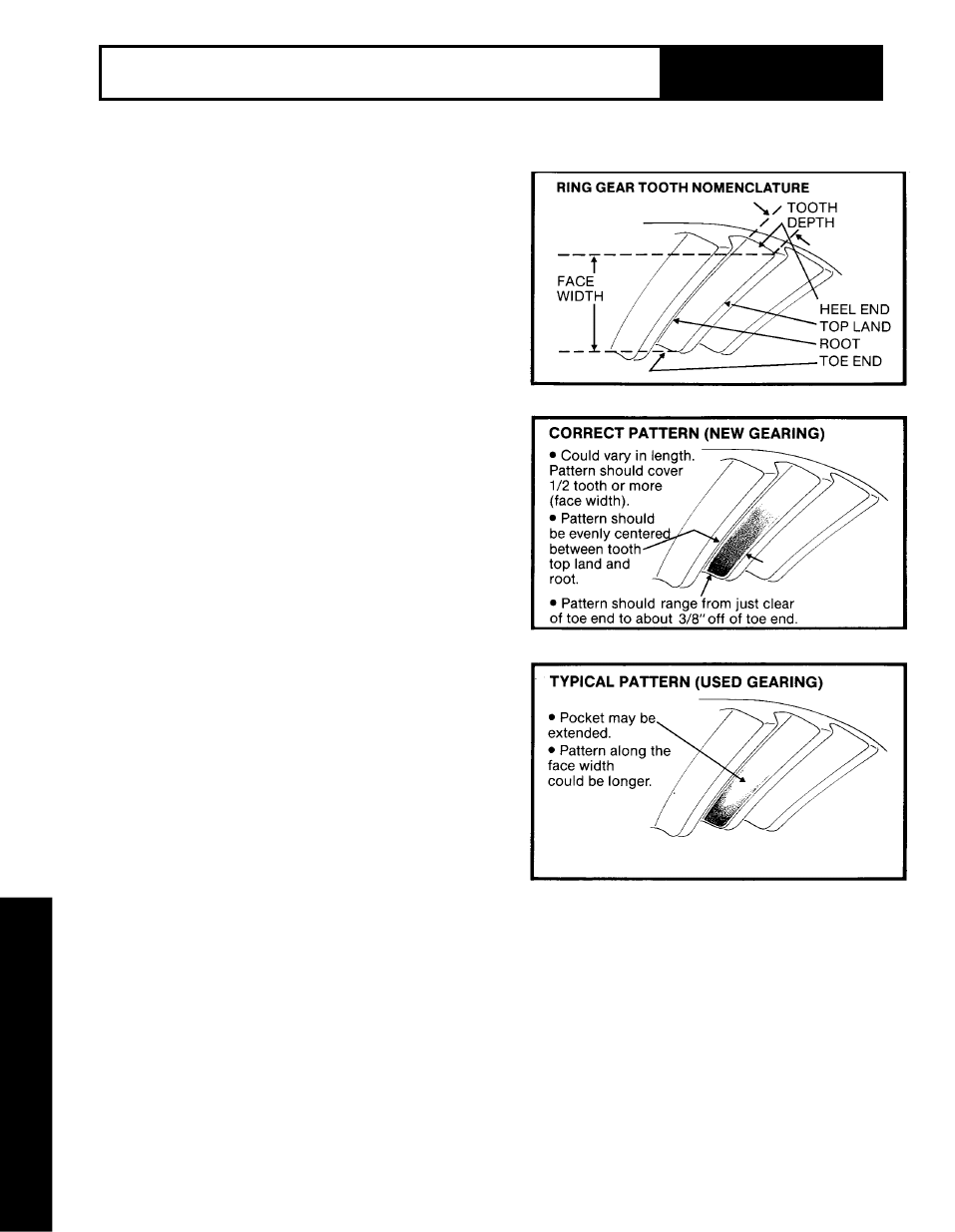

Adjust Ring Gear Tooth Contact

After differential bearing preload and gear

backlash adjustment is complete, check

gear tooth contact pattern and adjust if

necessary.

CORRECT TOOTH CONTACT PATTERN

(NEW GEARING)

Paint ring gear teeth with marking

compound and roll the gear to obtain a

contact pattern as shown in the drawings.

The length of the pattern in an unloaded

condition is approximately one-half to two-

thirds of the ring gear tooth in most models

and ratios.

CORRECT TOOTH CONTACT PATTERN

(USED GEARING)

Used gearing may not display the square,

even contact pattern found in new gear

sets. The gear may have a "pocket" at heel

end of contact pattern. The more use a gear

has had, the more the pocket becomes the

dominant characteristic of the pattern.

Adjust used gear sets to display the same

contact pattern observed before dis-

assembly. A correct pattern is up slightly off

the toe and centers evenly along the face

width between the top land and root.

Otherwise, the length and shape of the

pattern are highly variable and are con-

sidered acceptable as long as there is some

pattern on toe end of the tooth.

NOTE:

Tooth contact patterns are a function of the relative positions of the ring gear

and pinion. An improper pattern will require relocation of either or both. Always adjust

pinion position first, if necessary, then ring gear position. Recheck backlash when done.

28

Section

3

ADJUSTMENT

Drive Axle

Overhaul