Maintenance / adjustment, Periodic service – Spicer Drive Axles Service Manual Single Axles 2-Speed & Double Reduction User Manual

Page 8

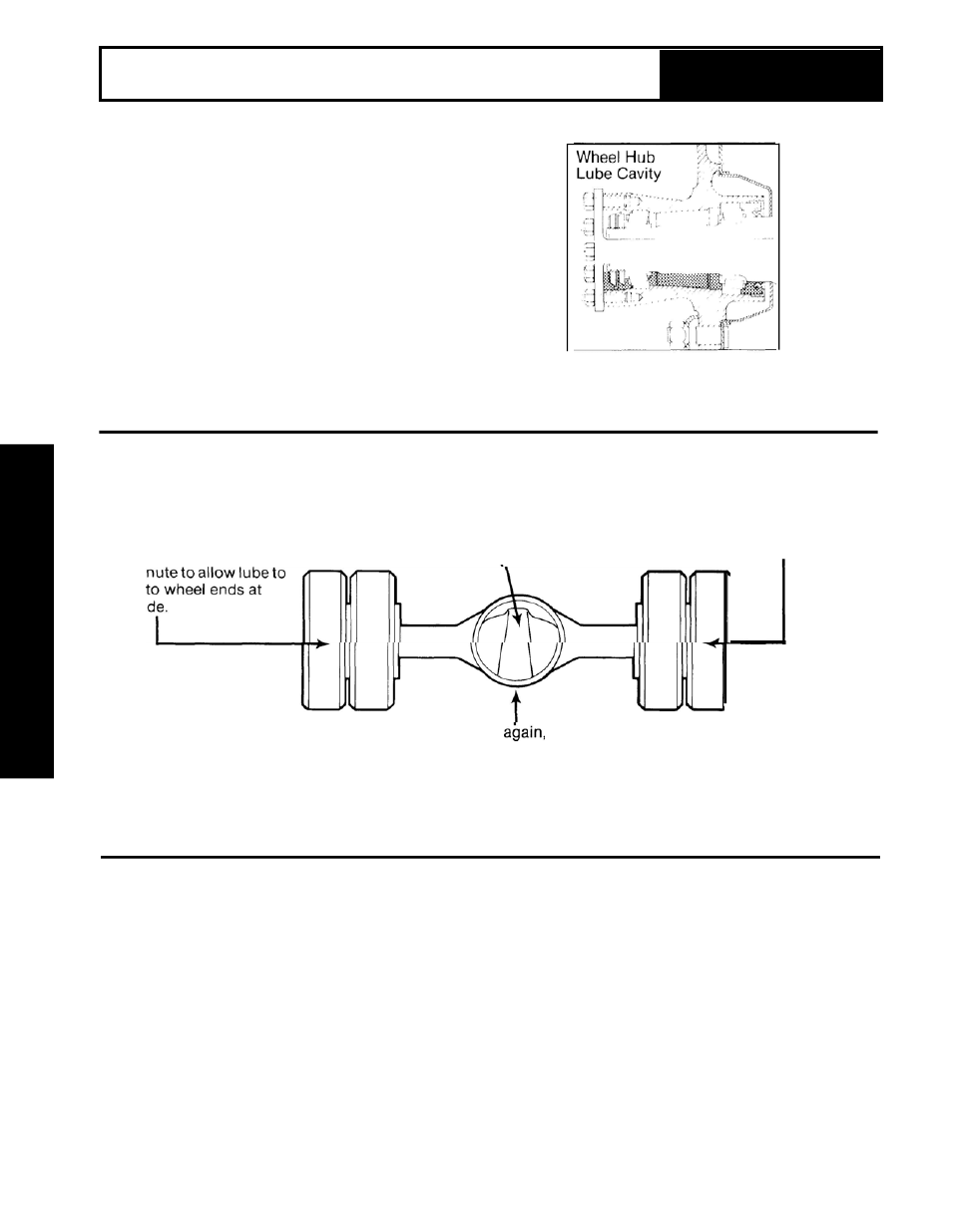

Wheel End Lubrication

IMPORTANT: In cases where wheel

equipment is being installed, either new or

after maintenance activity, the lube cavities

are empty. Bearings and seals must be

manually supplied with adequate lubricant

or they will be severely damaged before the

normal motion of the vehicle can supply

lube to the hub ends of the housing.

To avoid the risk of premature damage to

being installed. There are two methods of

wheel bearings and seals, they must be

doing this. The correct method will depend

"prelubed" any time the wheel equipment is

on the type of wheel equipment being used.

Lubrication When Hubs Have No Filler Holes (Preferred Method*)

(Follow procedure in numerical sequence.)

3. Jack up right side of

axle. Maintain this position

1. Fill axle with lube through axle housing cover filler hole.

for one minute to allow

2. Jack up left side of axle.

Maintain this position for

\

lube to flow into wheel

ends at left side.

one mi

flow in

right si

4. With vehicle level

add lube

through axle housing cover filler hole. The

axle should require two additional pints of

lube to bring level up to bottom of filler hole.

*The above procedure is the preferred method since it optimizes the lube supply to the

wheel end components and axle sump.

Hubs Equipped with Lube Filler Holes

Pour a pint of standard axle lubricant into

the hub through the cavity filler hole

provided.

8

Section 2

MAINTENANCE / ADJUSTMENT

Periodic

Service