Assembly / adjustment, Drive axle overhaul – Spicer Drive Axles Service Manual Single Axles 2-Speed & Double Reduction User Manual

Page 30

Adjust Ring Gear Tooth Contact

(cont'd)

When preload, backlash, and tooth contact

bearing cap screws to correct

are correct, align differential bearing adjust-

torque (see chart, back page)

ers and locks, then tighten differential

Differential Carrier Final Assembly

1.

Install adjuster lock and cap screw on ring

gear teeth side.

2. 2-Speed

Axles

(on backface side of ring

qear): Install adjuster lock, dowel bushings

and cap screws: Torque cap screws (see

chart, back page). Lockwire differential

bearing cap, and adjuster lock cap screws.

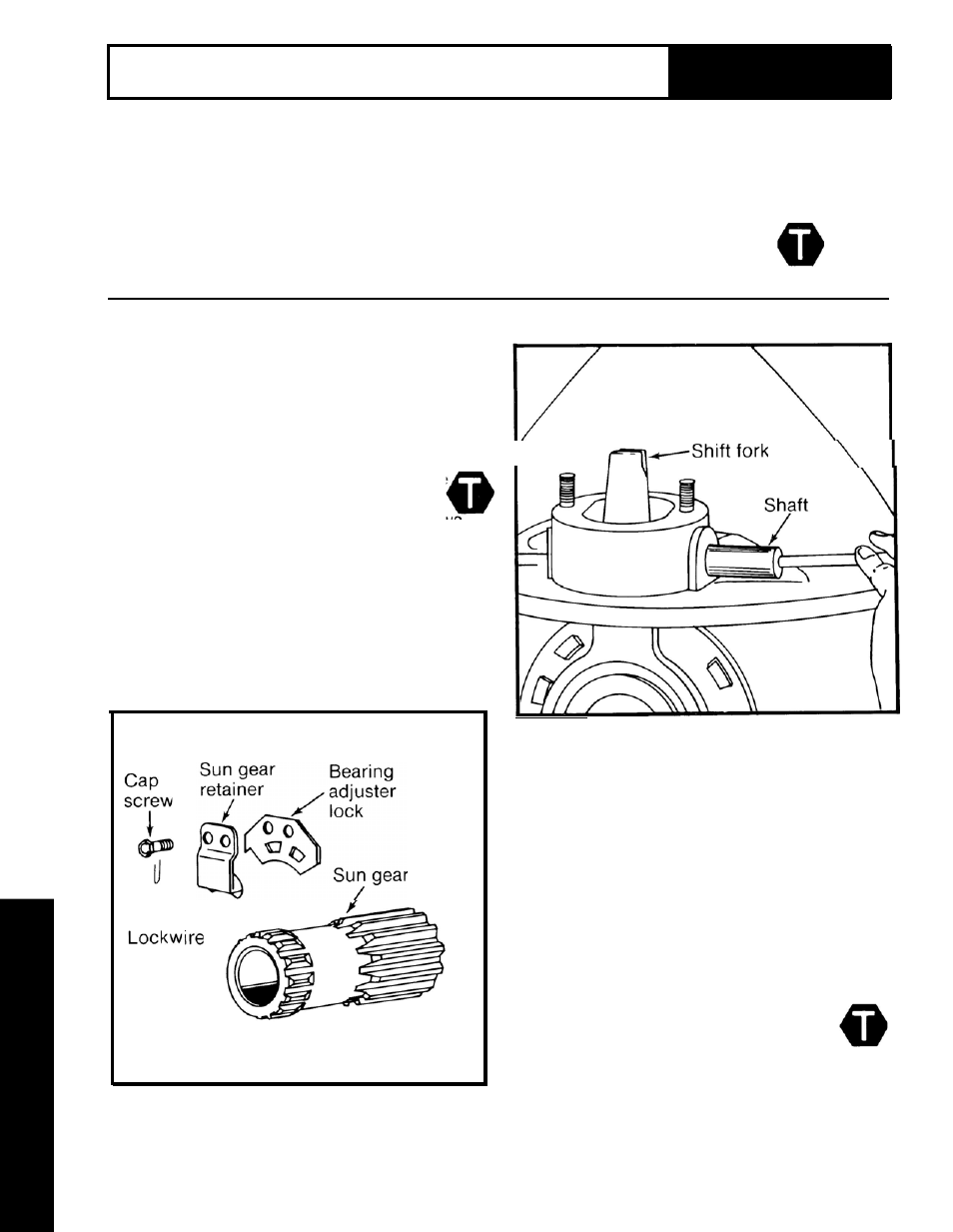

3. 2-Speed Axles: Position shift fork in

carrier opening, then install sliding clutch.

With clutch installed, engage shift fork yoke

with clutch collar. Then install shift fork

shaft. Install expansion plugs to seal

openings. Install shift unit seal and spring.

t

SUN GEAR COMPONENTS

NOTE: Lockwire used on all Early Axle

Models and Late Axle Model 35055P.

r

IMPORTANT (2-SPEED AXLES) Electric

shift unit replacement. Before installing a

rebuilt or new shift unit, check fit of shift

fork to slider block pivot using a "Fit-Up"

Card or Template (P/N 128039.)

These cards are furnished with new shift

units, retrofit and slider block kits.

Instructions are contained on the card or

refer to Spicer Service Manual EA-29.

4. Planetary Double Reduction Axles (on

backface side of ring gear): Install sun gear

and retainer, then install cap screws that

fasten both retainer and adjuster lock.

Tighten screws to correct torque (see

chart, back page) and lockwire.

Lockwire cap screws when used. See

illustration for application.

30

Section 3

ASSEMBLY / ADJUSTMENT

Drive Axle

Overhaul