Maintenance / adjustment, Periodic service, Lube change intervals – Spicer Drive Axles Service Manual Single Axles 2-Speed & Double Reduction User Manual

Page 7: Changing lube, Guidelines - lube change intervals for drive axles, Lube capacities do not overfill axles

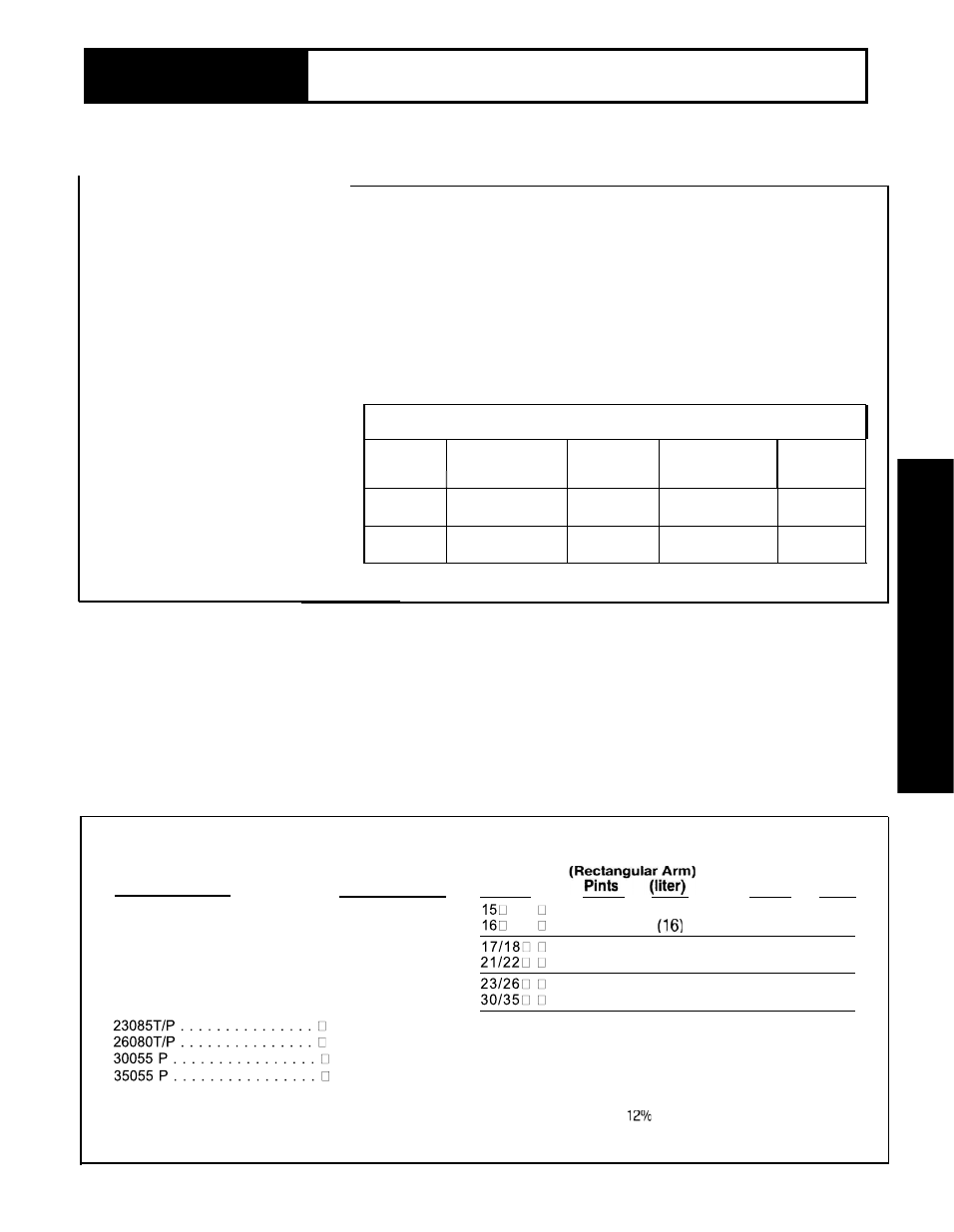

Lube Change Intervals

Lubrication Change Internals -

General:

The initial lubricant

change is one of the most

important factors in axle com-

ponent life and durability, because

of the elimination of break-in

contaminants. These contaminants

are primarily iron from the initial

break-in wear of rotating

components, and silicon from the

sand used in manufacture of cast

components.

For either a new or rebuilt drive

axle, the lubricant should be

changed within the first 3000 to

5000 miles of operation.

Subse-

quent lubricant changes should be

based on a combination of the

intervals stated in the following

chart and user judgment based

heavily on the application and

operating environment.

Changing Lube

Lubrication Change Intervals -

NOTE: At both the initial and all

Severe

Service:

Severe service

subsequent lubricant changes,

applications are those which

Spicer recommends that the

require the axle to be consistently

magnetic filler and drain plugs,

operated near it•s maximum GCW

and the breather be cleaned.

or GVW ratings, dusty or wet

environments, or consistent opera-

tion on grades greater than 8%

.

For these applications, the ON/OFF

HIGHWAY portion of the chart

should be used.

Guidelines - Lube Change Intervals for Drive Axles

I

Maximum

On/Off Highway

Maximum

Lubricant

On Highway

Change

Severe Service

Change

Type

Miles

Interval

Miles

Interval

,

r

1

1

I

Mineral

100,000

Yearly

40

,000

Yearly

Based

Spicer

Approved

250,000

3 Year

100

,000

Yearly

Synthetlc

NOTE: After initial lube change, the entire

DRAINING: Drain into suitable container

with lube at normal operating temperature.

Inspect drain plug for excessive metal

particle accumulation symptomatic of

extreme wear. Clean and replace plug after

draining.

unit should be inspected if excessive

particle accumulation is observed.

FILLING: Remove filler hole plug and fill

housing with approved lubricant until level

with bottom of filler hole.

Late Axle Model

15040T/P . . . . . . . . . . . . . . .

19050T/P . . . . . . . . . . . . . . .

19055T/P, 19060T/P . . . . . .

21060T/P, 21065T/P,

22060T/P, 22065 T/P . . .

23070T/P . . . . . . . . . . . . . . .

23080T/P . . . . . . . . . . . . . . .

Lube Capacities DO NOT OVERFILL AXLES

Pints

24.0

33

35

35

39.0

41

(Liters)

(17.3)

(15.6)

(16.6)

(16.6)

(18.4)

(19.0)

Early

Spicer Housing

Vendor Housing

Axle

(Round Arm)

Series

Pints

(liter)

23

(11)

19

( 9)

33

24

(11)

37

(18)

29

(14)

37

(18)

-

41

(19)

34

(16)

41

(19)

41

(19.0)

41

(19.0)

36

(17.0)

36

(17.0)

NOTE: Capacities

do not apply to housings not designed by Spicer

Axles installed at angles exceeding 6

o

or operated regularly on grades exceeding

may require stand-pipes to allow

proper fill levels. For specific information, contact your Dana representative at phone numbers listed on back cover of

this manual.

7

MAINTENANCE / ADJUSTMENT

Periodic

Service

Section 2

-

- - -

-

-