Installation of inter-axle differential to carrier, Yoke removal & seal replacement, Installation of inter-axle differnetial to carrier – Spicer Tandem Drive Axles Service Manual S400 User Manual

Page 27: Yoke removal and seal replacement

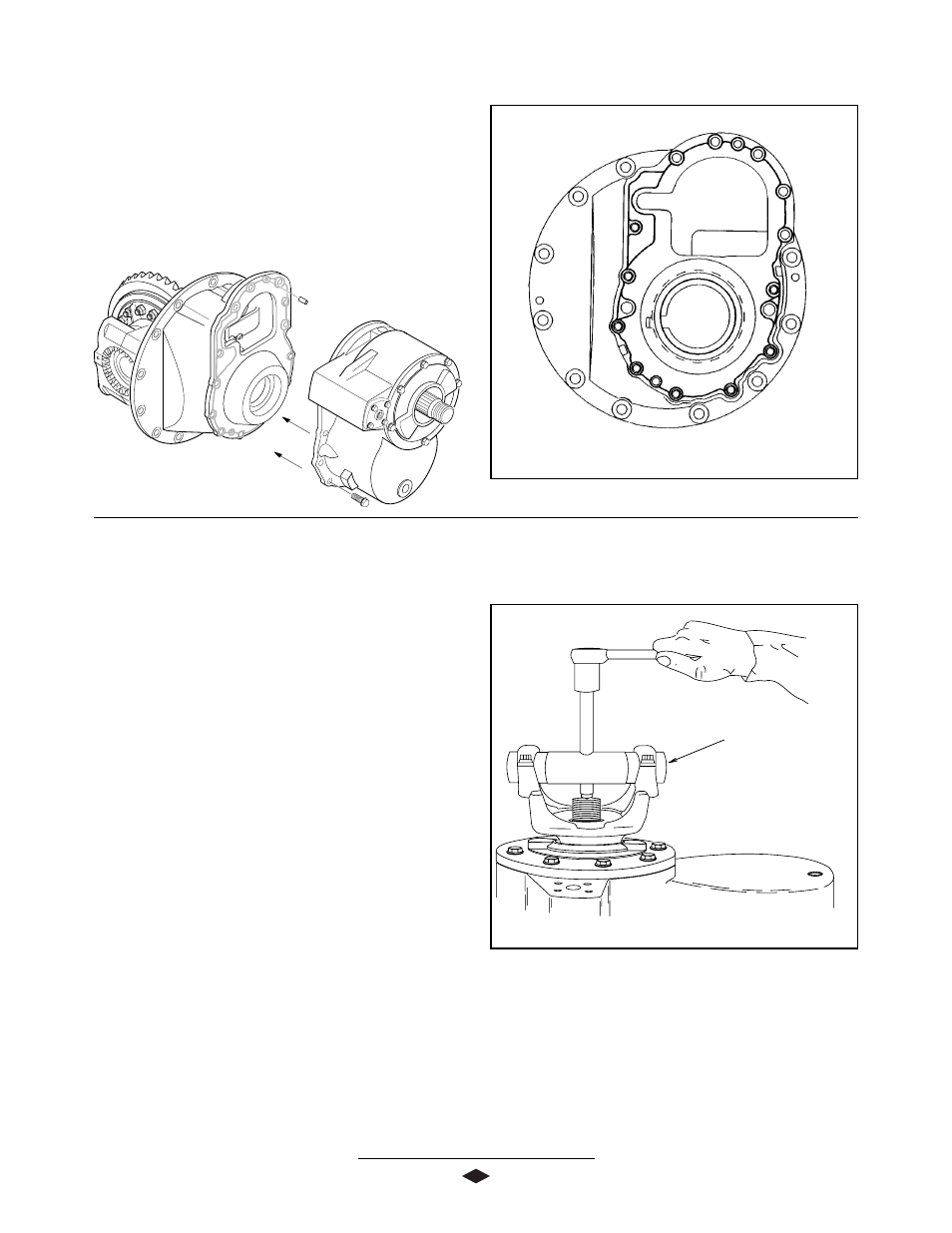

INSTALLATION OF INTER-AXLE DIFFERNETIAL TO CARRIER

1. Thoroughly clean mating face of carrier and apply

an 1/8 inch bead of Loctite #518 Gasket Elimina-

tor. See Figure 19 for correct bead pattern.

2. Align inter-axle differential case with carrier housing

and insert bolts and torque to 160-180 Lb-Ft

(217-244 N-m).

FFFFFigur

igur

igur

igur

igure 1

e 1

e 1

e 1

e 19

9

9

9

9

#518 Gasket Eliminator Bead Pattern

Yoke Remover

FFFFFigur

igur

igur

igur

igure 2

e 2

e 2

e 2

e 25

5

5

5

5

YOKE REMOVAL AND SEAL REPLACEMENT

1. Disconnect drive shaft at the rear U-joint.

2. Remove yoke nut.

NOTE: Use of torque multiplier is recommended as

torque specification on input flanged hex nut is 900-

1,200 Lb-Ft (1,220-1,627 N-m).

3. Remove end yoke using the yoke remover tool. See

Figure 25.

4. Remove oil seal.

5. Inspect end yoke seal surface for grooves. If grooves

can be detected with fingernail, it should be repaired

with a CR SPEEDI-SLEEVE

®

or replaced.

6. Clean and dry threads on input/ouput shaft or

pinion. Install oil seal using proper tools.

7. Install end yoke using yoke installer. See Figure 17

on page 17.

NOTE: Spicer recommends that new flanged hex nuts

be used.

8. Apply Loctite #680 (green) to threads.

9. Use torque multiplier and torque flanged hex nut to

900-1,200 Lb-Ft (1,220-1,627 N-m).

Yoke Removal and Seal Replacement Complete

25