Inter-axle differential assembly – Spicer Tandem Drive Axles Service Manual S400 User Manual

Page 24

22

INTER-AXLE DIFFERENTIAL ASSEMBLY

23. Apply a thin coat of grease to the small diameter of

the shift shaft.

24. Insert shift shaft into cylinder and install through

the shift fork hole and the spring. Make sure shaft is

seated into the bottom of the shift cylinder.

25. Apply a thin coat of grease to the O-ring of the shift

piston.

NOTE: Visually inspect the composite shift piston to

insure the steel spacer is present on the bottom of the

piston. See page 26 for more piston information.

26. Lubricate and place piston/O-ring assembly into

shift cylinder with detailed side facing front for the

composite piston and the flat face on the aluminum

piston.

See Figure 27 on page 26. Seat piston

firmly against shift shaft.

27. Install onto the shift cover.

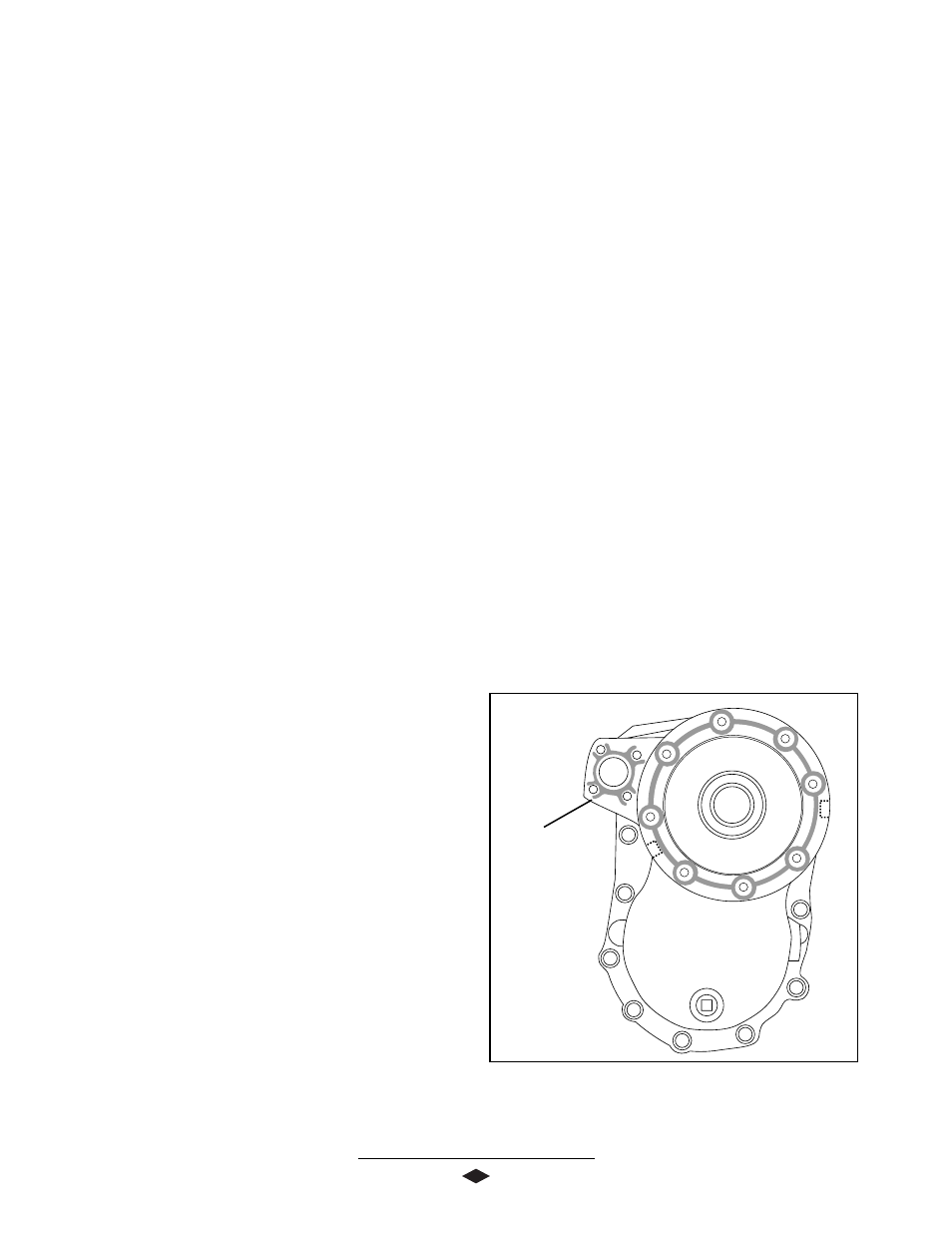

28. Clean the shift cover sealing area and the intermedi-

ate case and apply a 1/16 in. bead of Loctite #518

Gasket Eliminator.

See Figure 22.

NOTE: Care must be taken to keep Loctite off of

piston assembly.

29. Install shift cover.

NOTE: If old bolts are used, coat threads with Loctite

#277 before installing.

30. Install four washers and cover bolts. Tighten and

torque bolts alternately to 15-20 Lb-Ft (20-27 N-

m) until cover is seated properly.

31. Lube bearing and bearing journals then Install the

input shaft into the shift collar and lube input shaft

bearing.

of case and around each bolt hole.

See Figure 22.

34. Install bearing retainer and tighten bolts alternately.

Torque bolts 100-120 Lb-Ft (135-163 N-m).

35. Inspect input yoke seal surface for grooves. If

grooves can be detected with fingernail, it must be

repaired with a CR SPEEDI-SLEEVE

®

or replaced.

36. Clean and dry threads on input shaft.

37. Install end yoke using installer service tool.

NOTE: Spicer recommends that new flanged hex nuts

be used.

38. Apply Loctite #680 (green) to threads.

39. Use torque multiplier and torque input flanged hex

nut to 900-1,200 Lb-Ft (1,220-1,627 N-m).

Inter-axle Assembly Complete

Loctite #518

Gasket Eliminator

FFFFFigur

igur

igur

igur

igure 2

e 2

e 2

e 2

e 22

2

2

2

2

32. Install new oil seal into input shaft bearing retainer.

33. Clean the mating surfaces of the bearing retainer

and the case. Apply a 1/16 in. bead of Loctite

#518 Gasket Eliminator to cover mounting surface

22. Assemble the shift collar onto the shift fork with

flat side of collar up. The fork bushing must also

face up. Install the fork and collar into the case and

align the hole of the shift fork over the opening of

the spring.