Pinion disassemly, Pinion disassembly – Spicer Tandem Drive Axles Service Manual S400 User Manual

Page 16

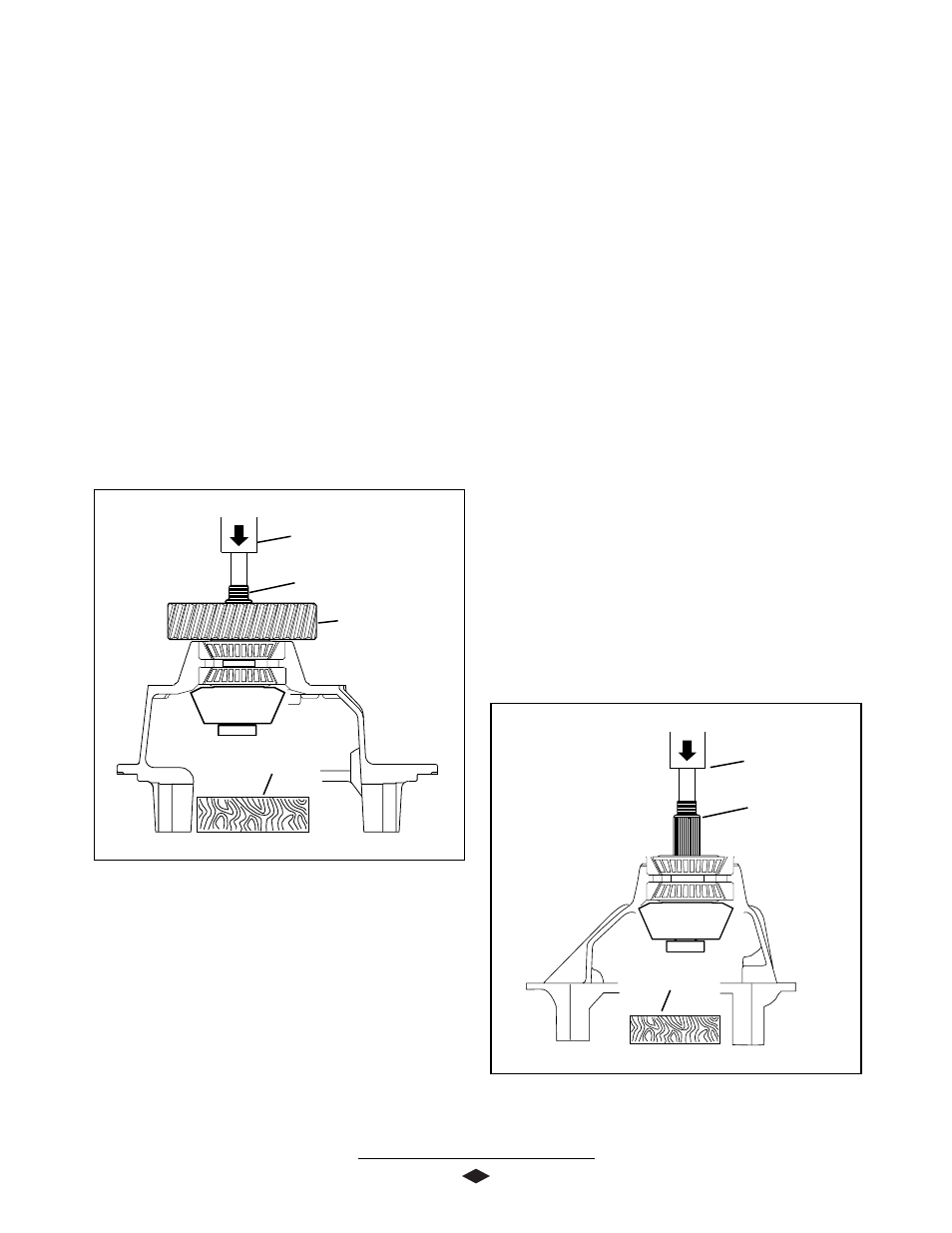

PINION DISASSEMBLY

1. Remove flanged hex nut.

NOTE: Use of a torque multiplier is recommended.

Torque flanged hex nut to 900-1,200 Lb-Ft (1,220-

1,627 N-m).

2. Remove end yoke on the rear rear axle using a

suitable puller. Refer to

RECOMMENDED

SERVICE TOOLS, pgs. 29-30).

3. Remove the oil seal on the rear rear axle and

discard.

4. Remove the four pinion pilot bearing support bolts.

5. Remove the pinion pilot bearing support.

6. Place carrier in press with threaded end of pinion

face up.

See Figure 10 and 10A.

7. Place a wooden block under pinion to avoid damage

of gear teeth during removal.

8. Pinion removal -

•

On the

Forward Rear, press the pinion through

the helical driven gear and inner and outer

bearing cones.

See Figure 10.

•

On the

Rear Rear, press the pinion through the

inner and outer bearing cones.

See Figure 10A.

9. Remove the pinion from the bottom of the carrier.

10. Remove bearing preload spacer and save for use in

reassembly.

11. If the gearset is to be reused, remove inner pinion

bearing with a suitable puller at this time. If the

gear set is to be replaced new bearings must be

installed.

12. If bearings are to be replaced, press bearing cups

out of carrier casting at this time.

13. Remove pinion pilot bearing with a suitable puller.

Pinion Disassembly Complete

Press

Pinion

Driven Gear

Wood Block

FFFFFigur

igur

igur

igur

igure 1

e 1

e 1

e 1

e 10

0

0

0

0

14

Press

Pinion

Wood Block

FFFFFigur

igur

igur

igur

igure 1

e 1

e 1

e 1

e 10A

0A

0A

0A

0A