Differential disassembly – Spicer Tandem Drive Axles Service Manual S400 User Manual

Page 15

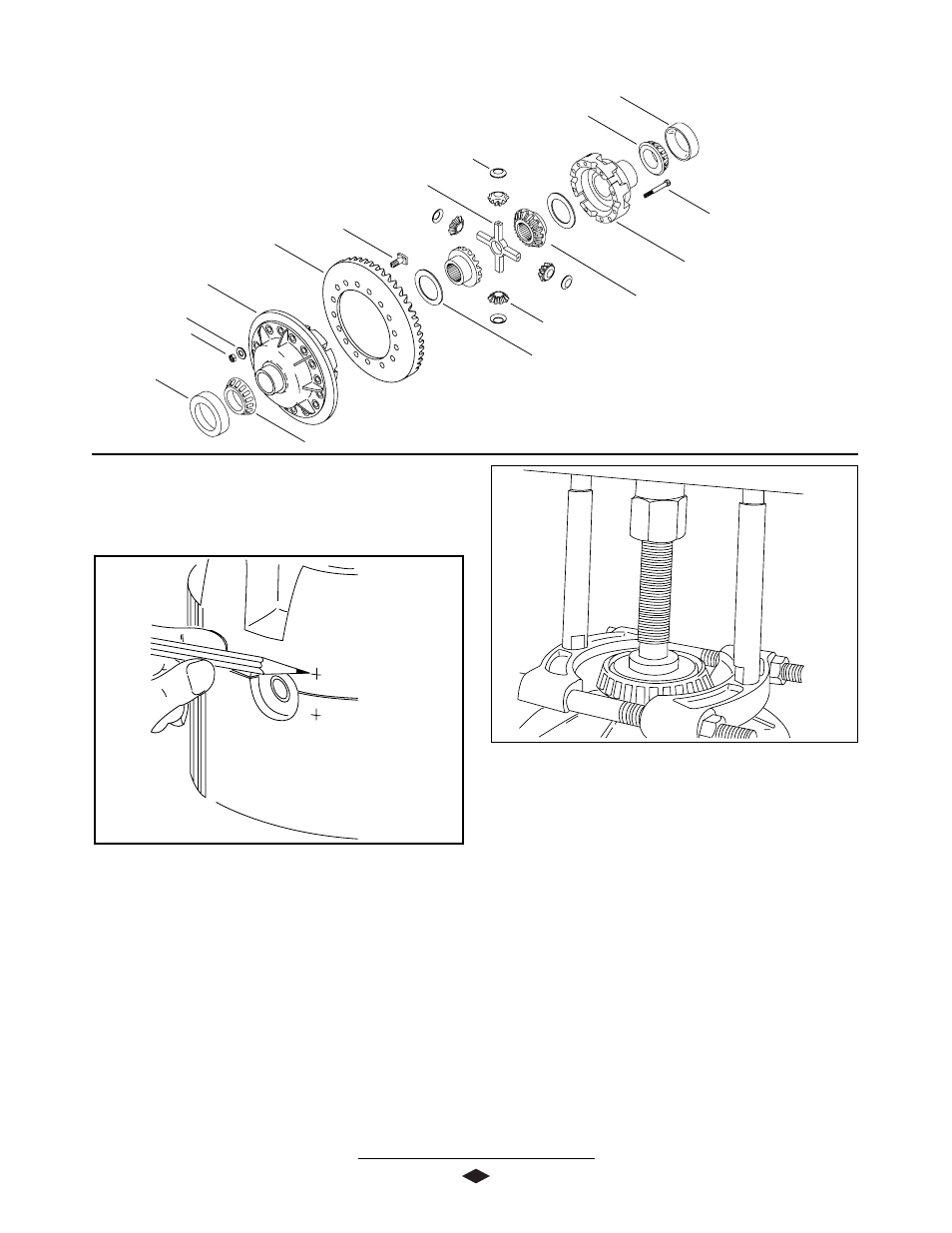

DIFFERENTIAL DISASSEMBLY

FFFFFigur

igur

igur

igur

igure 8

e 8

e 8

e 8

e 8

1. Match mark differential case halves with a punch or

chisel for correct alignment in reassembly.

See

Figure 8.

Nut

(300-320 Lb-Ft)

(407-434 N-m)

Flat Washer

Flange Half

Differential Case

Ring Gear

Differential Cross Shaft

Bearing Cone

Bearing Cup

Differential Case Bolt

(180-200 Lb-Ft)

(244-271 N-m)

Plain Half

Differential Case

Differential Pinion Mate

Gear Thrust Washer

Bearing Cone

Bearing Cup

FFFFFigur

igur

igur

igur

igure 9

e 9

e 9

e 9

e 9

NOTE: Inspect all parts including the machined

surfaces of the case itself.

IMPORTANT: If any gears are to be replaced, they

must be replaced in sets. Inspect thrust washers for

scoring and excessive wear. Replace all worn or

damaged parts.

7. When it is necessary to remove ring gear from

differential case, carefully loosen ring gear nuts with

breaker bar in an alternating pattern and remove.

IMPORTANT: Do not damage ring gear when loosening

ring gear nuts.

8. Inspect ring gear, ring gear bolts, and ring gear bolt

holes for nicks, excessive wear, and irregularities.

Differential Disassembly Complete

Pinion Mate Thrust Washer

Bolt

13

Differential Gear

2. Remove differential case bolts and lift off the

differential case half.

3. Remove thrust washer and differential gear.

4. Lift out cross shaft, pinion mates and pinion mate

thrust washers.

5. Remove second differential gear and thrust washer.

6. If differential bearings are to be replaced, remove

old bearings using a suitable puller.

See Figure 9.