Ouput shaft assembly, Output shaft assembly – Spicer Tandem Drive Axles Service Manual S400 User Manual

Page 22

20

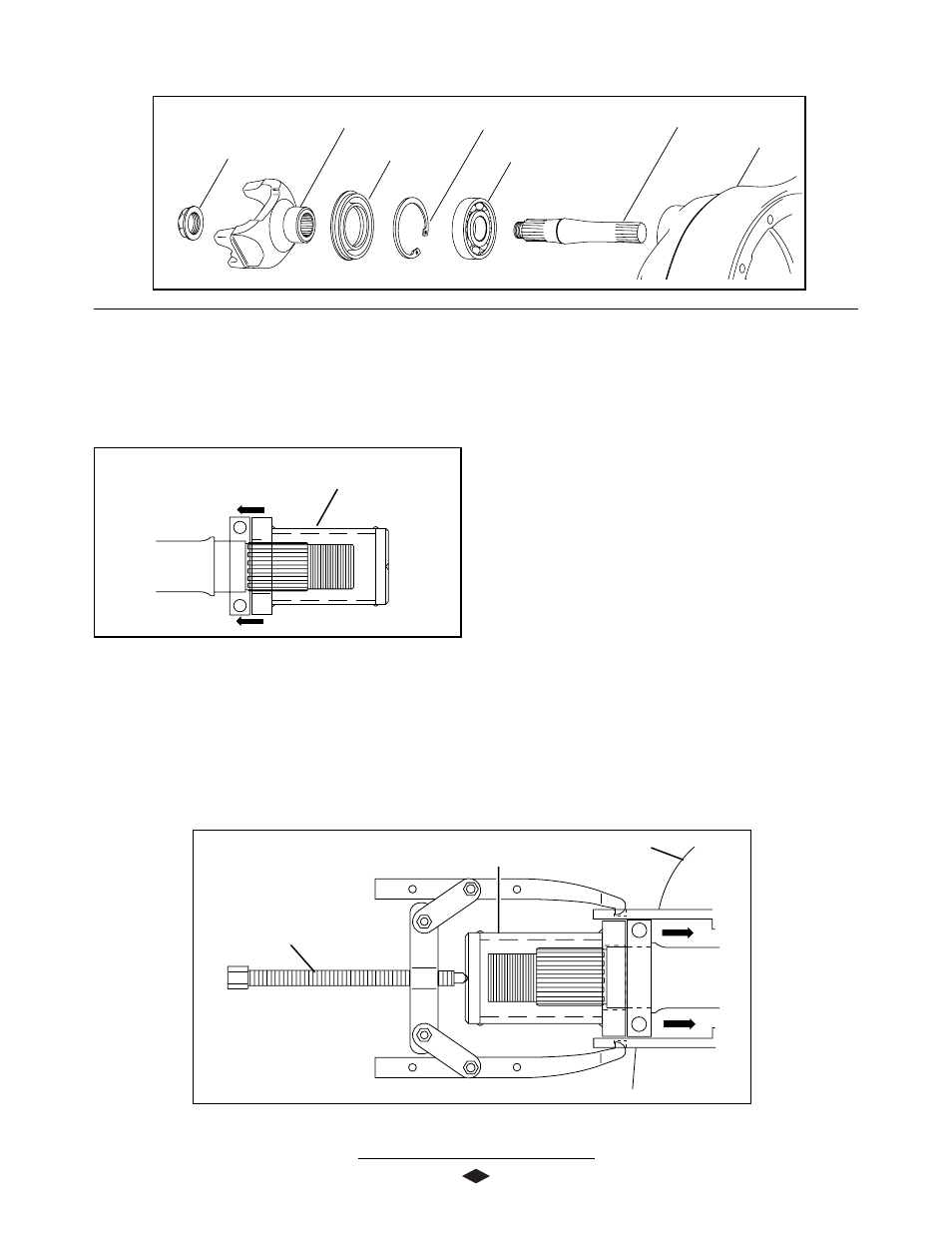

OUTPUT SHAFT ASSEMBLY

Bearing Installer

Service Tool

Housing

Output Shaft

Flanged Hex Nut

(900-1,200 Lb-Ft)

(1,220-1,627 N-m)

End Yoke

Output Oil Seal

Beveled Retaining Ring

Output Shaft Bearing

Housing

1. Press new bearing onto shaft using output shaft

bearing installer service tool.

See Figure 19.

NOTE: Clean bore of housing to remove old Loctite

and oil.

2-Jaw Puller

F

F

F

F

Figur

igur

igur

igur

igure 2

e 2

e 2

e 2

e 20

0

0

0

0

2. Apply a thin layer of Loctite #620 to the outside

diameter of the bearing before assembly into

housing.

NOTE: Care must be taken to keep Loctite out of

bearing.

Bearing Installer

Service Tool

FFFFFigur

igur

igur

igur

igure 1

e 1

e 1

e 1

e 19

9

9

9

9

3. Install output shaft and bearing assembly into

housing using bearing installer service tool withad-

equate 2 jaw puller.

See Figure 20.

4. Seat bearing completely in housing and remove

excess Loctite.

5. Install beveled retaining ring in housing with bevel

facing to the rear of the axle. Be certain the

retainer ring is fully seated. Clean and dry threads

on output shaft.

6. Lubricate bearing with hypoid axle lube.

7. Install oil seal using proper service tools.

8. Install end yoke using yoke installer service tool.

9. Apply Loctite #680 to threads before installing new

flanged hex nut.

10. Use torque multiplier and torque flanged hex nut to

900-1,200 Lb-Ft (1,220-1,627 N-m).

Output Shaft Installation Complete