Battery construction – Power-Sonic Sealed Lead Acid Batteries - Technical Manual User Manual

Page 4

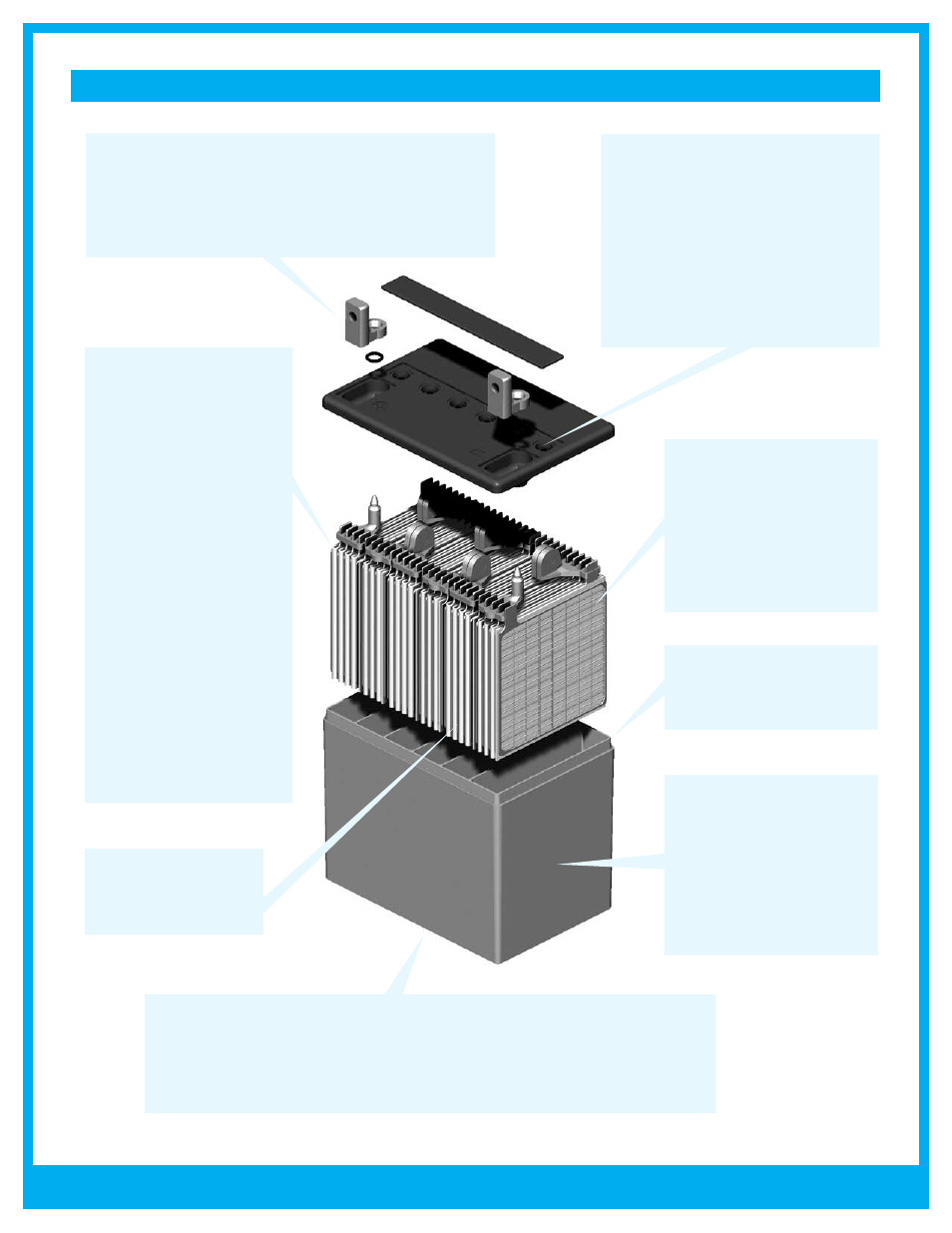

Battery Construction

Relief valve

In case of excessive gas pressure build-up

inside the battery, the relief valve will open

and relieve the pressure. The one-way valve

not only ensures that no air gets into the

battery where the oxygen would react with

the plates causing internal discharge, but

also represents an important safety device in

the event of excessive overcharge.

Vent release pressure is between 2-6 psi; the

seal ring material is neoprene rubber

.

Terminals

Depending on the model, batteries come either with AMP Faston type

terminals made of tin plated brass, post type terminals of the same

composition with threaded nut and bolt hardware, or heavy duty flag

terminals made of lead alloy.

A special epoxy is used as sealing material surrounding the terminals.

Electrolyte

Immobilized dilute sulfuric

acid: H

2

S0

4

.

Separators

Power-Sonic separators are made

of non-woven glass fiber cloth

with high heat and oxidation

resistance. The material further

offers superior electrolyte

absorption and retaining ability,

as well as excellent ion

conductivity.

Plates (electrodes)

Power-Sonic utilizes the latest

technology and equipment to

cast grids from a lead-calcium

alloy free of antimony. The

small amount of calcium and

tin in the grid alloy imparts

strength to the plate and

guarantees durability even in

extensive cycle service. Lead

dioxide paste is added to the

grid to form the electrically

active material.

In the charged state, the

negative plate paste is pure

lead and that of the positive

lead dioxide. Both of these are

in a porous or spongy form to

optimize surface area and

thereby maximize capacity. The

heavy duty lead calcium alloy

grids provide an extra margin of

performance and life in both

cyclic and float applications and

give unparalleled recovery from

deep discharge.

Leakproof Design & Operational Safety

The leak proof construction of Power-Sonic batteries has

ensured that our batteries have been approved for

shipment by air, both by D.O.T. and I.A.T.A. Copies of

these approvals are available on our website:

www.power-sonic.com.

U.L’s component recognition

program for emergency lighting and

power batteries lists Power-Sonic

under file number MH20845

Case Sealing

Depending on the model the case

sealing is ultrasonic, epoxy or

heat seal.

Container

Case and lid material is ABS,

high impact, resin with high

resistance to chemicals and

flammability. Case and cover are

made of non-conductive ABS

plastic to UL94-HB or UL94 V-O.

This case has molded-in dividers

for each 2 volt cell.