York DNH018 User Manual

Page 28

036-21233-002-A-0903

28

Unitary Products Group

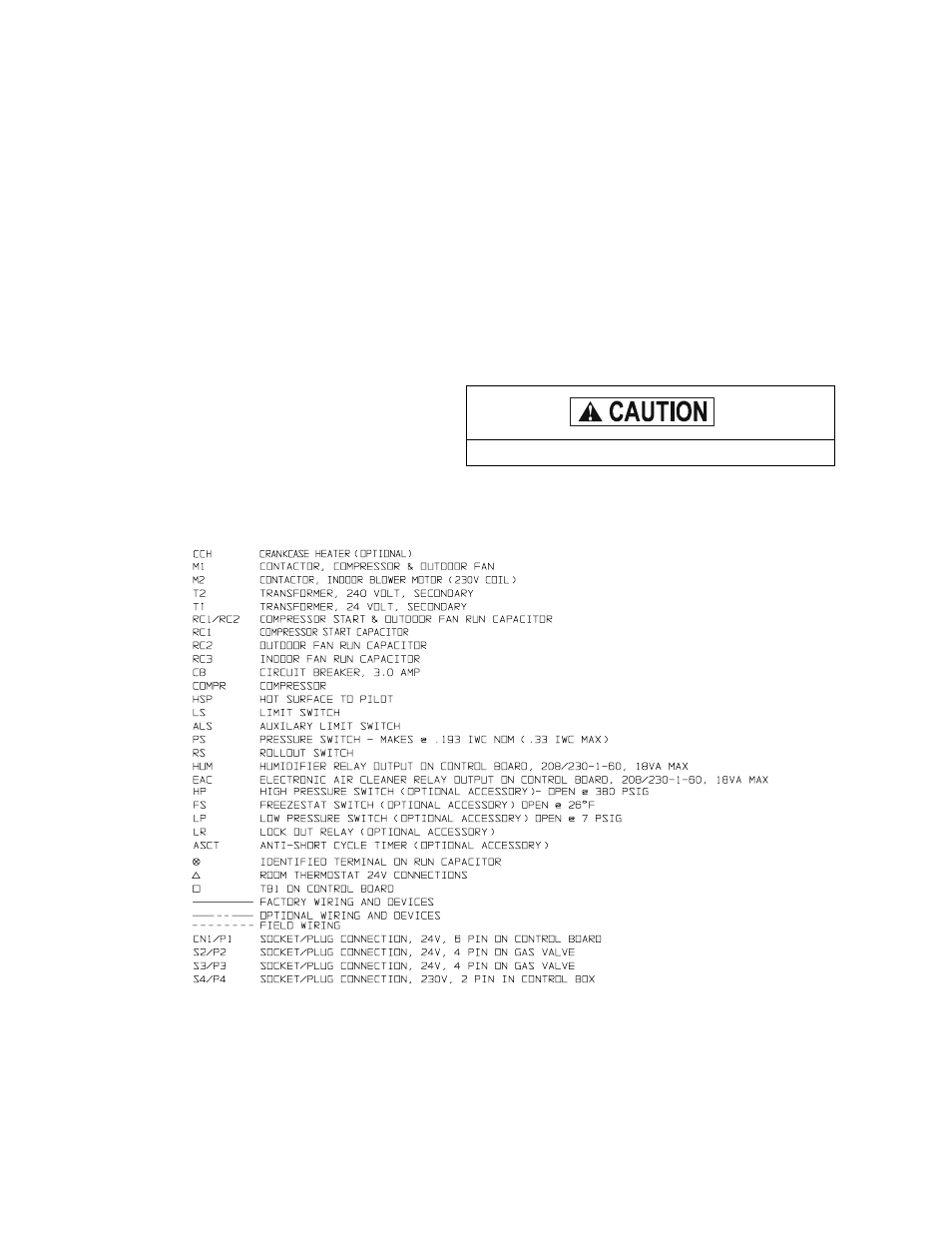

TYPICAL WIRING DIAGRAM NOTES

1.

All field wiring to be accomplished following city, local

and/or national codes in effect at time of installation of

this unit.

2.

Caution: Label all wires prior to disconnection when ser-

vicing controls. Wiring errors can cause improper and

dangerous operation if any of the wire as supplied with

this unit must be removed it must be replaced with type

105°C, 600V wire or equivalent clearly renumbered for

identification. Verify proper operation after servicing.

3.

Motors are inherently protected.

4.

See unit nameplate for maximum fuse size and minimum

circuit ampacity.

5.

Unit factory wired for low or medium speed indoor blower

operation to change motor speed connect speed tap

wires from indoor blower motor per Detail B (Figure 18)

tape unused speed tap wires to prevent shorting and

secure near M2 contactor.

6.

Select indoor blower speed to remain within the temper-

ature rise range on the nameplate in heating and to

obtain approximately 400 CFM/Ton in cooling.

7.

If both LR and ASCT are present, wire 801/BL and 805/

BL are connected to ASCT-3 if LR only is present wire

801/BL and 805/BL are connected to M1 coil. If ASCT

only is present wire 202/Y is connected to ASCT-3. If

neither LR or ASCT are present, Wire 202/Y is connect

to M1 coil.

8.

Shunt contact also used with crankcase heater.

(Optional).

FIGURE 17 - TYPICAL WIRING DIAGRAM LEGEND

1

Open all disconnects before servicing this unit.

(ALTERNATE)

(ALTERNATE)

1. See Figures 13, 14, 15 and 16.