Toshiba RAV-SM800XT-E User Manual

Page 40

– 38 –

CAUTION

•

Do not apply excess torque. Otherwise, the nut

may crack depending on the conditions.

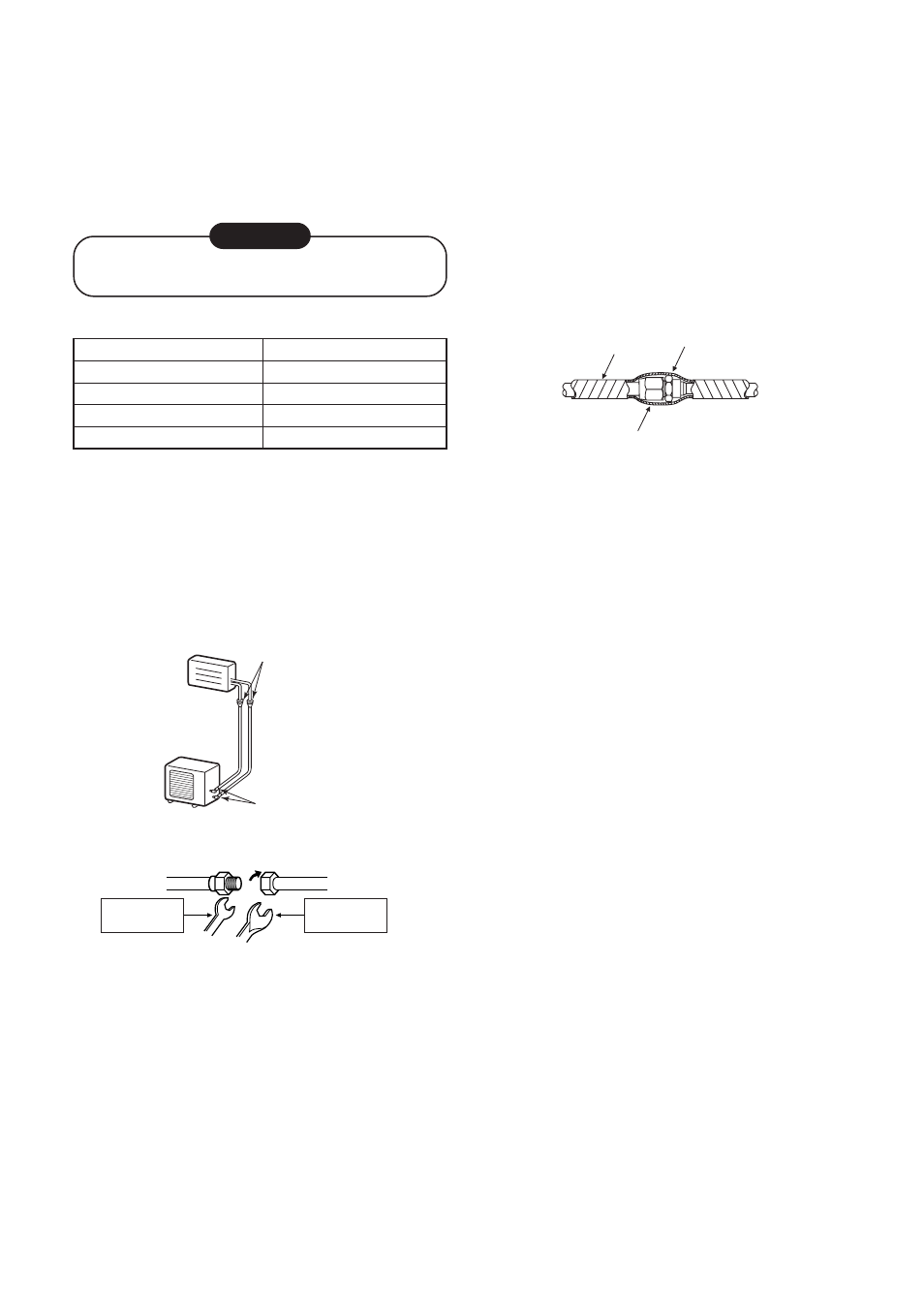

Align the centers of the connecting pipes and tighten

the flare nut as far as possible with your fingers. Then

tighten the nut with a spanner and torque wrench as

shown in the figure.

(Unit : N•m)

Outer diam. of copper pipe

Tightening torque

6.35 mm (diam.)

14 to 18 (1.4 to 1.8 kgf•m)

9.52 mm (diam.)

33 to 42 (3.3 to 4.2 kgf•m)

12.7 mm (diam.)

50 to 62 (5.0 to 6.2 kgf•m)

15.9 mm (diam.)

63 to 77 (6.3 to 7.7 kgf•m)

Flare at

indoor unit side

Flare at

outdoor unit side

Flare nut

Half union

Use a wrench to secure.

Use a torque wrench to tighten.

Externally

threaded side

9-7-3. Pipe Shield for Flare Nut Connection

Joints in liquid and gas pipes of the indoor unit should

be insulated with an attached Pipe shield

$

.

1. Cut the Pipe shield

$

to appropriate length.

2. Set the Pipe shield

$

.

3. In case of a ceiling installation, orient the slit at the

top of the pipe.

4. Fix the Pipe shield

$

with vinyl tape.

Fig. 9-7-5

$

$

$

$

$

Pipe shield

Vinyl tape

Slit

Internally

threaded side

•

Tightening torque of flare pipe connections

Pressure of R410A becomes higher than that of

R22. (Approx. 1.6 times) Therefore, using a torque

wrench, tighten firmly the flare pipe connecting

sections which connect the indoor and outdoor units

up to the specified tightening torque.

Incorrect connections may cause not only a gas

leakage, but also a trouble of the refrigeration cycle

or compressor damage.

Fig. 9-7-3

Fig. 9-7-4