Maintenance – Tiger Products Co., Ltd CNH T6010-80 User Manual

Page 134

MAINTENANCE

Boom

Maintenance Section 4-14

©2011 Alamo Group Inc.

MAINTENANCE

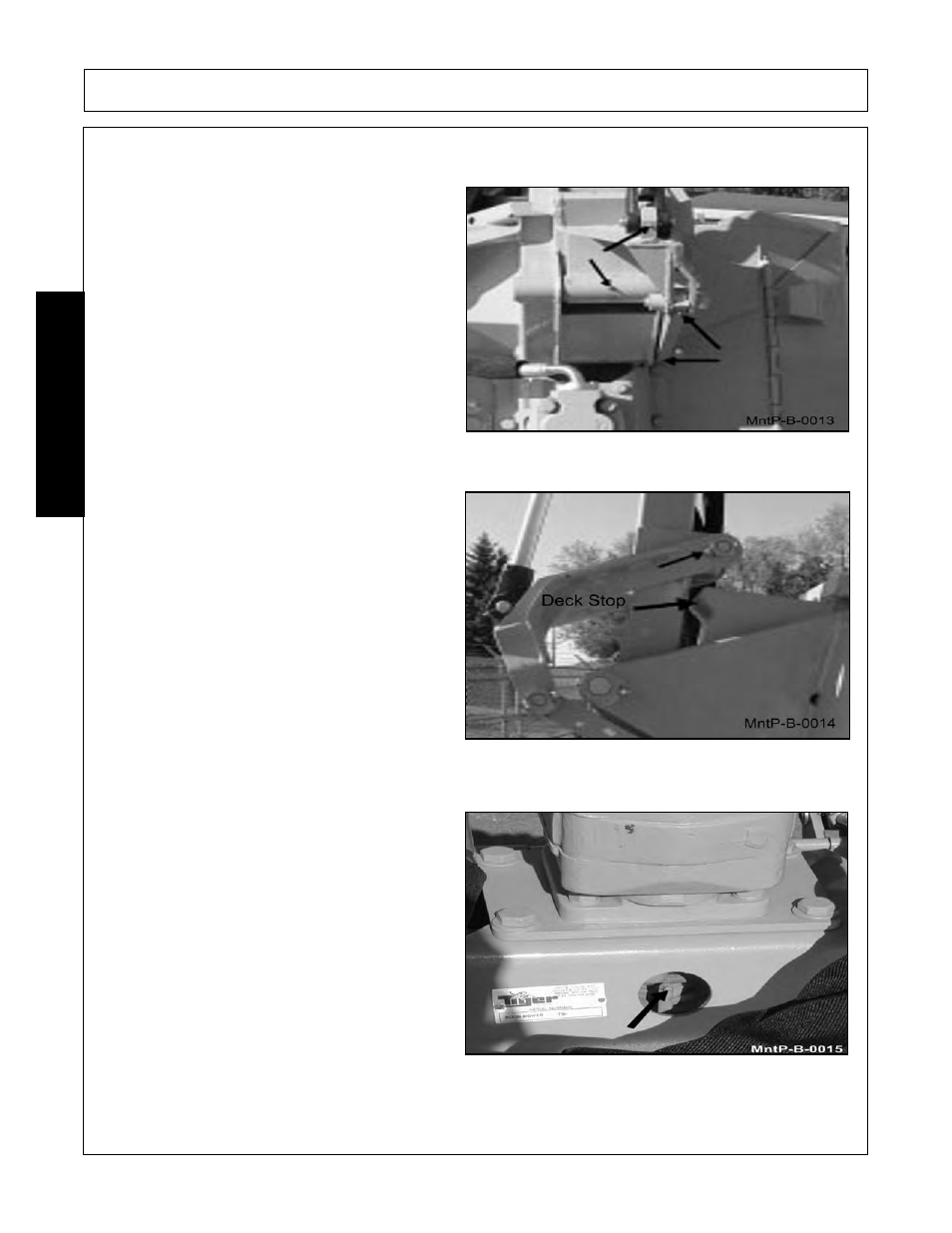

GREASING POINTS ON BOOM AND PIVOT

Locate grease zerks on deck pivot ssembly, on the

deck end of secondary boom, at main/secondary

boom joint, and at swivel end of main boom. Inject

Lithium-Complex Extreme Pressure grease

conforming to NLGI2-ISO 320 specifications until

grease begins to protrude from ends.

DECK STOP ADJUSTMENT

On boom flail, loosen locking nut. Turn adjustment

bolt in, and run deck cylinder out to full extension.

Adjust bolt out until the head just touches the boom,

and tighten lock nut. NOTE: Bolt should not hit

boom before cylinder reaches full travel.

GREASING SPINDLE

Locate grease fitting on inside of deck housing.

Inject Tiger Spindle Lubricant, part number

06540000 into spindle housing. Fill with lubricant

until lubricant weeps out of top spindle seal.

Lubricate spindle weekly or every 40 hours of use.