60(86) control keypad – Nx Networks NX series User Manual

Page 60

60(86)

Control keypad

7

7.3.4.2 Fault

codes

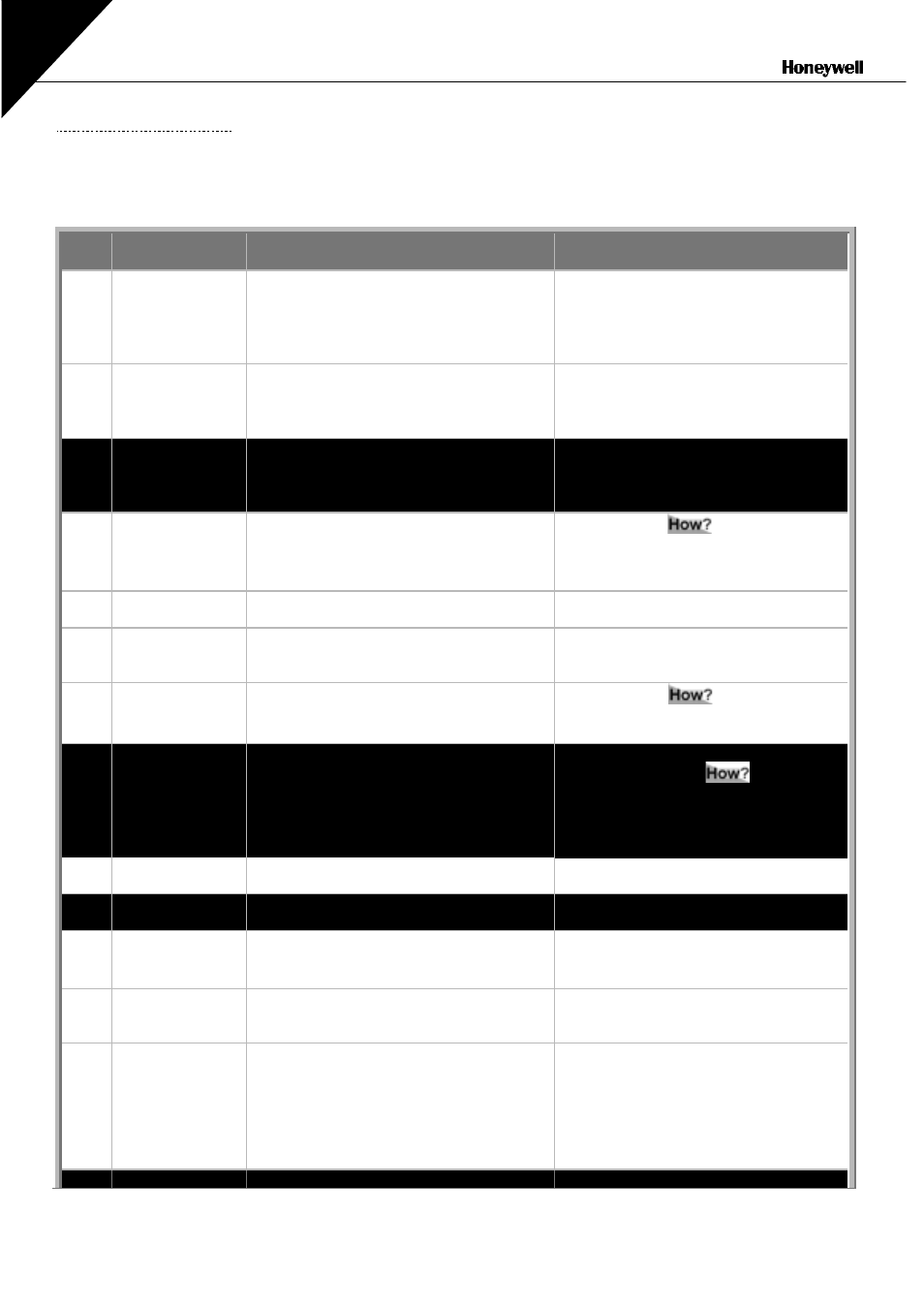

The fault codes, their causes and corrective actions are presented in the table below. The

shadowed faults are A faults only. The faults written in white on black background may appear as

both A and F fault.

Fault

code

Fault

Possible cause

Correcting measures

1

Overcurrent

Frequency converter has detected too

high a current (>4*I

n

) in the motor cable:

−

sudden heavy load increase

−

short circuit in motor cables

−

unsuitable

motor

Check loading.

Check motor.

Check cables.

2

Overvoltage

The DC-link voltage has exceeded the

limits defined in Table 4-1.

−

too short a deceleration time

−

high overvoltage spikes in supply

Make the deceleration time longer. Use

brake chopper or brake resistor

(available as options)

3

Earth fault

Current measurement has detected that

the sum of motor phase current is not

zero.

−

insulation failure in cables or motor

Check motor cables and motor.

5

Charging switch

The charging switch is open, when the

START command has been given.

−

faulty

operation

−

component

failure

Reset the fault

and restart.

Should the fault re-occur, contact your

nearest distributor..

6

Emergency

stop

Stop signal has been given from the

option board.

7

Saturation trip

Very high overload

Defective component

Cannot be reset from the keypad.

Switch off power. If this does not help

contact your nearest distributor.

8

System fault

The frequency converter troubleshooting

system is unable to locate the fault.

Reset the fault

and restart.

Should the fault re-occur, contact your

nearest distributor.

9

Undervoltage

DC-link voltage is under the voltage limits

defined in.

−

most probable cause: too low a

supply voltage

−

frequency converter internal fault

In case of temporary supply voltage

break reset the fault

and restart

the frequency converter. Check the

supply voltage. If it is adequate, an

internal failure has occurred.

Contact your nearest distributor.

10

Input line

supervision

Input line phase is missing.

Check supply voltage and cable.

11

Output phase

supervision

Current measurement has detected that

there is no current in one motor phase.

Check motor cable and motor.

12

Brake chopper

supervision

−

no brake resistor installed

−

brake resistor is broken

−

brake chopper failure

Check brake resistor.

If the resistor is ok, the chopper is faulty.

Contact your nearest distributor..

13

Frequency

converter under-

temperature

Heatsink temperature is under –10

°

C

14

Frequency

converter over

temperature

Heatsink temperature is over 90

°

C.

Over temperature warning is issued when

the heatsink temperature exceeds 85

°

C.

Check the correct amount and flow of

cooling air.

Check the heatsink for dust.

Check the ambient temperature.

Make sure that the switching frequency

is not too high in relation to ambient

temperature and motor load.

15

Motor stalled

Motor stall protection has tripped.

Check motor.