Stock out adjustment, Knife square adjustment, Headlift sensor – Paxar 656 / 636 User Manual

Page 43: Full stacker sensor - jam sensor

Users Manual Model 656/636

Maintenance / Adjustments

• 37

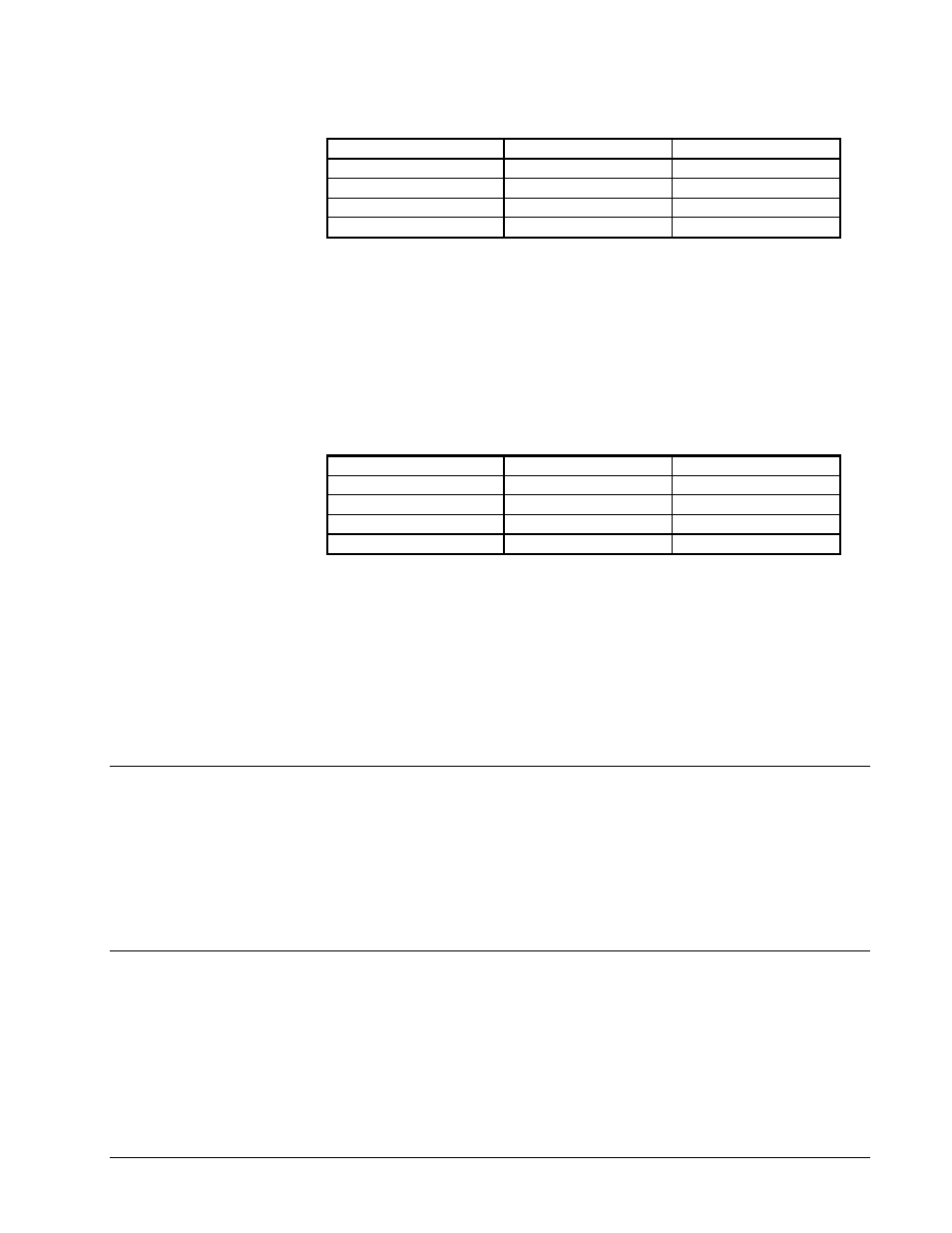

Headlift Sensor

Sensor Blocked

Sensor Not Blocked

Test Point:

TP18

TP18

Adjustment Pot

R52

R52

#7 Light Status:

On

Off

Desired Voltage:

> 3.50 VDC

< 0.75 VDC

The Headlift Sensor allows the printer to register the platen roller on 656 printers.

Begin by rotating the platen roller until the flag is blocking the sensor. The platen

roller has been slotted to accept a regular screwdriver on the front of the machine to

assist in this operation. Adjust the pot until the high value is achieved. Then rotate

the platen roller until the flag is no longer blocking the sensor. Adjust the pot until

the low level is met. The low level is the more crucial of the two adjustments.

NOTE: The same pot is used for both adjustments and a compromise value must be

achieved.

Full Stacker Sensor - Jam Sensor

Sensor Blocked

Sensor Not Blocked

Test Point:

TP11

TP11

Adjustment Pot

R48

R48

#6 Light Status:

On

Off

Desired Voltage:

> 3.50 VDC

< 0.75 VDC

The Full Stacker Sensor allows the printer to detect a full load of labels in the

stacker. The stack full condition will be detected by a switch and will stop the

machine when the stacker is full. The Jam Sensor feature will detect each cut label

as it leaves the cutter. If a cut fails to occur, the machine will stop. To adjust the

jam sensor, block the sensor and adjust the pot until the high value is achieved.

Remove the block from the sensor and adjust the pot until the low level is met. The

low level is the more crucial of the two adjustments.

NOTE: The same pot is used for both adjustments and a compromise value must be

achieved.

Stock out Adjustment

The stock out sensor has been set at the factory, however for some stocks it may be

necessary to adjust the sensor to detect stock out. With a full roll of stock loaded in

the machine, run the printer and observe how far behind the stock (to the left of the

stock) the stock out wire rod is located. This should be between 1/4 and 1/2 inch (6

to 12mm) behind the running stock. If not, loosen the set screw and rotate the wire

to the acceptable distance and re tighten.

Knife Square Adjustment

The knife has an adjustment to square the cut to the stock. To make the adjustment,

loosen the two cap screws, one on top of the knife and one below the knife, using the

3/16 ball driver in the tool kit. Move the knife in the direction desired to square the

cut and re tighten.