Theory of operation – Lincoln Electric PIPELINER 200 User Manual

Page 66

THEORY OF OPERATION

E-4

E-4

PIPELINER® 200

BATTERY, STARTER, ENGINE

ALTERNATOR, OIL, & TEMPERATURE

SWITCH CIRCUITS

The 12VDC battery powers the starter motor and,

through the ignition switch, the engine ignition circuitry

(gas models only), the engine alternator, the engine

control protection modules and associated circuits.

See the appropriate block diagram. These engine con-

trol and protection modules monitor engine oil pres-

sure, coolant temperature and engine RPM. The sys-

tem shuts the engine down in the event of a sudden

low oil pressure or high coolant temperature. A warn-

ing light on the control panel provides fault codes, or on

some models the engine fault light will glow.

The engine idle control (solenoid, throttle plates or

actuator) is mechanically connected to the engine.

When welding current or auxiliary power (120VDC) is

drawn through the current sensing P.C. board a small

voltage signal is sent to the engine control circuitry.

This signals the engine control circuitry to increase the

engine RPM. This is accomplished in a variety of

methods depending upon the engine and con-

trol/protection being used.

When the welding or auxiliary load is removed a preset

time delay of about 15 seconds starts. After approxi-

mately 15 seconds of “no load” the engine con-

trol/protection circuitry returns the engine to low idle

RPM.

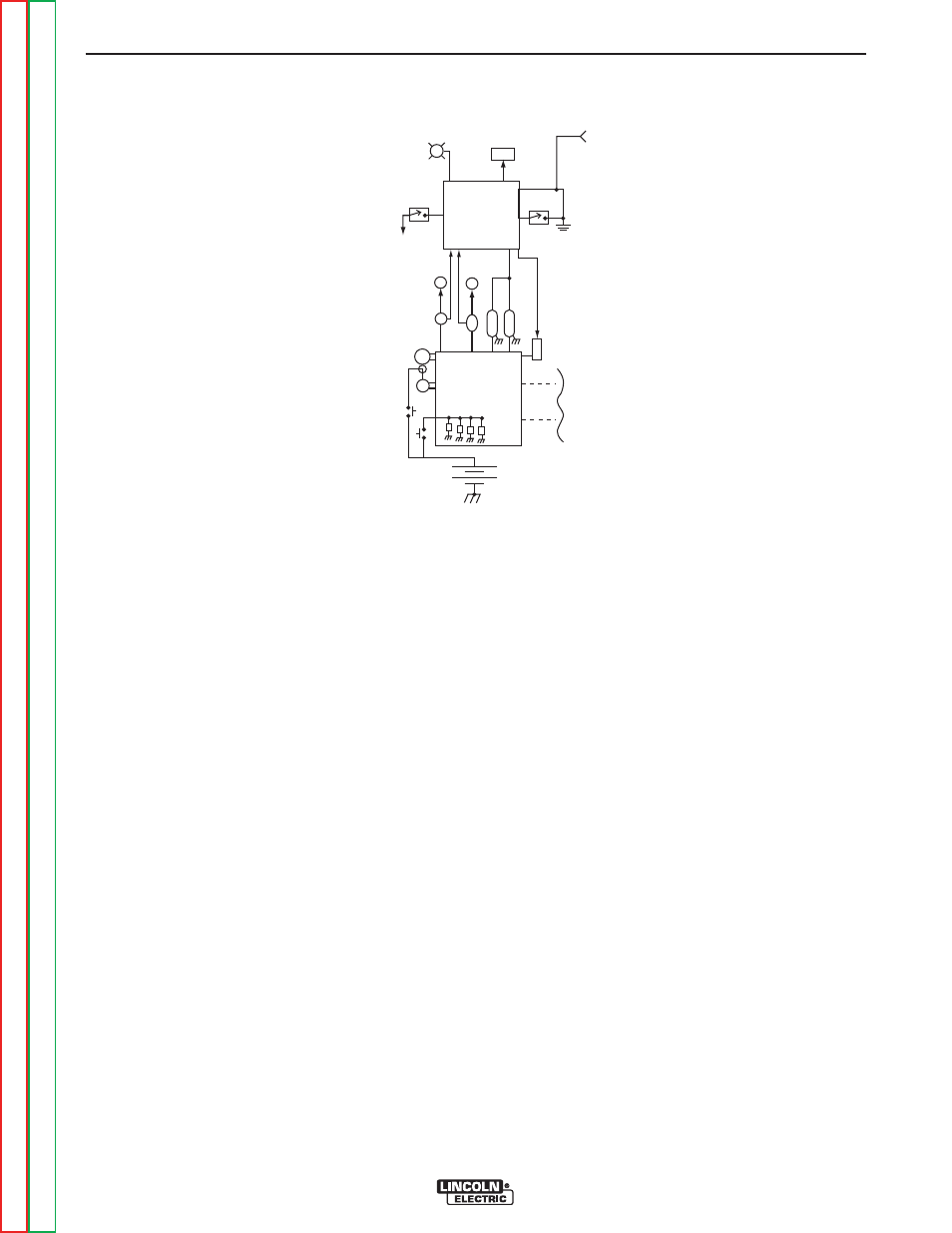

FIGURE E.4 — ENGINE CONTROL

ENGINE

IDLER

SOLENOID

12 VOLT

BATTERY

ENGINE

PERKINS DIESEL

FROM CURRENT

SENSING P.C. BOARD

IDLER

SWITCH

IDLER/ENGINE

PROTECTION

P.C. BOARD

ENGINE

FAILURE

LAMP

ENGINE

HOUR

METER

FUEL

PUMP

FUEL

SOLENOID

OIL

GAUGE

OIL

SENSOR

SWITCH

TEMP.

SENSOR

SWITCH

TEMP.

GAUGE

STARTER

MOTOR

ENGINE

ALTERNATOR

GLOW PLUGS

TO

BATTERY

IGNITION

SWITCH

COUPLED TO

GENERATOR