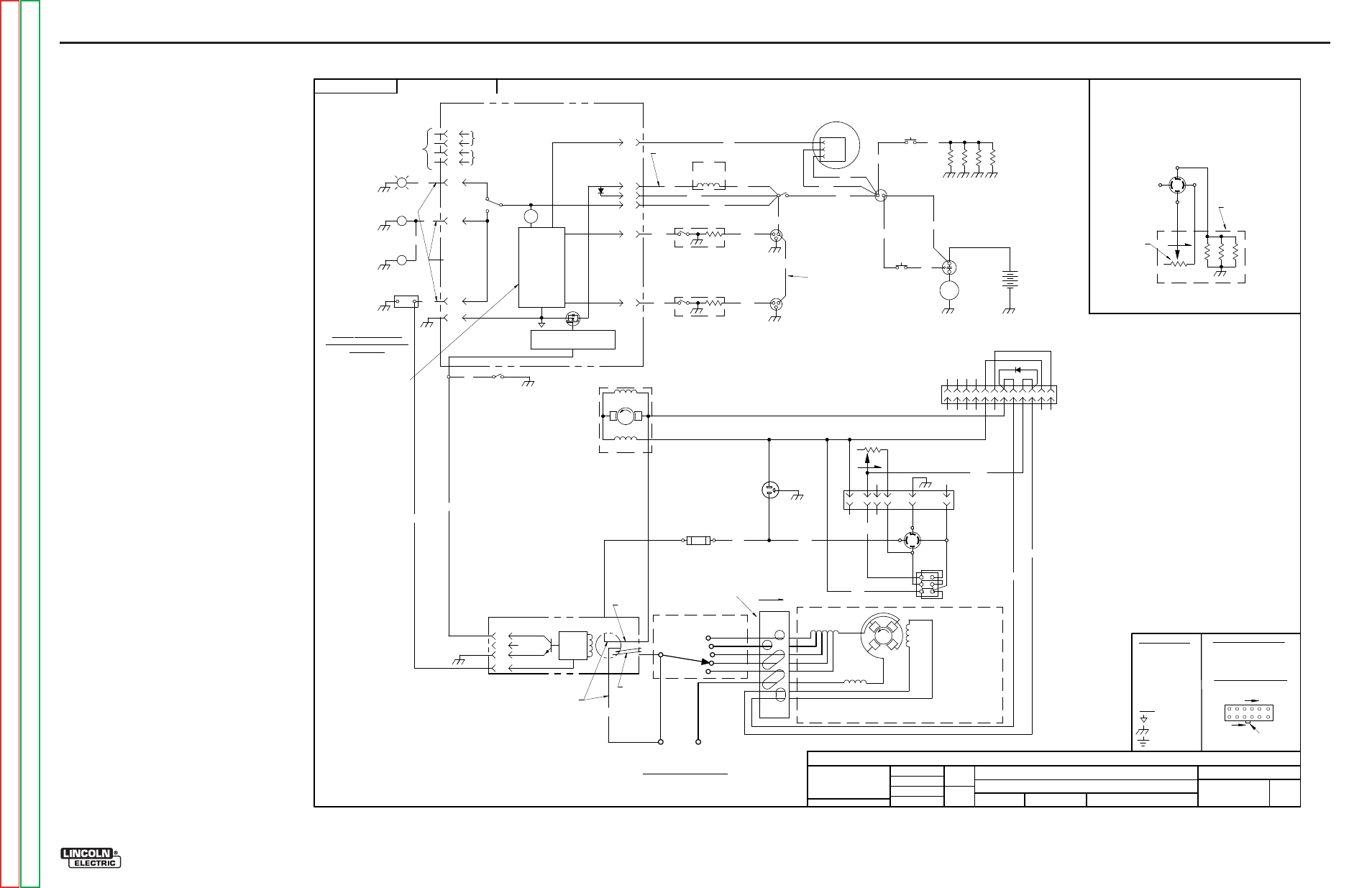

Electrical diagrams, K924-5 remote control (optional), Pipeliner® 200 – Lincoln Electric PIPELINER 200 User Manual

Page 141: Idler / engine protection pc board, Current sensing pc board, Welding generator dc exciter

ELECTRICAL DIAGRAMS

G-7

PIPELINER® 200

SCHEMATIC -COMPLETE MACHINE - CODE 10929 - (L12020)

L12020

PIPELINER 200D

MACHINE SCHEMATIC

NA

L11946

JRS

JRS

UNLESS OTHERWISE SPECIFIED TOLERANCE

MANUFACTURING TOLERANCE PER E2056

ON 2 PLACE DECIMALS IS ± .02

ON 3 PLACE DECIMALS IS ± .002

ON ALL ANGLES IS ± .5 OF A DEGREE

WITH PUBLISHED STANDARDS.

MATERIAL TOLERANCE (" ") TO AGREE

t

DO NOT SCALE THIS DRAWING

DRAWN BY:

DESIGN INFORMATION

ENGINEER:

APPROVED:

REFERENCE:

EQUIPMENT TYPE:

SUBJECT:

SCALE:

L12020

MATERIAL

DISPOSITION:

APPROVAL

DATE:

PROJECT

NUMBER:

UF

CRM33528

1

PAGE ___ OF ___

1

ENGINEERING CONTROLLED

MANUFACTURER:

No

DOCUMENT

NUMBER:

DOCUMENT

REVISION:

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OWNED BY LINCOLN GLOBAL, INC. AND MAY NOT BE DUPLICATED, COMMUNICATED

TO OTHER PARTIES OR USED FOR ANY PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF LINCOLN GLOBAL, INC.

PROPRIETARY & CONFIDENTIAL:

A

12/09/2002

Released A.01 from "X"

CHANGE DETAIL:

LEAD COLOR CODE:

B-BLACK OR GRAY

G-GREEN

O-ORANGE

R-RED OR PINK

U-BLUE

W-WHITE

Y-YELLOW

COMPONENT VALUE UNITS:

CAPACITOR: MFD/VOLTS

RESISTOR: OHMS/WATTS

CONNECTOR PIN NUMBERS:

VIEW OF CONNECTOR ON PC BOARD

1 2

6

7

12

LATCH

EX. 12 PIN CONNECTOR

LABELS:

COMMON

FRAME GROUND

EARTH GROUND

OIL PRESSURE SWITCH / SENDER

TEMPERATURE SWITCH / SENDER

+

BATTERY

STARTER

MOTOR

STARTER

SOLENOID

W

G

GLOW PLUG

SWITCH

START SWITCH

IGNITION

SWITCH

TEMPERATURE

GAUGE

S

I

G

OIL PRESSURE

GAUGE

S

I

G

AMMETER

+

-

BRUSH POSITION SHOWN AS

VIEWED FROM CONTROL PANEL

IDLER / ENGINE PROTECTION PC BOARD

J1-2

J1-1

J1-3

J1-6

J1-7

J1-8

J1-9

J1-5

J1-4

RED ENGINE

PROTECTION

LIGHT

J2-1

J2-2

J2-3

J2-4

R

IDLER SWITCH

J1-10

ALTERNATOR

WK

G

DC AUXILIARY

RECEPTACLE

NEGATIVE OUTPUT TERMINAL

POSITIVE OUTPUT TERMINAL

CURRENT SENSING PC BOARD

J3-4

J3-1

J3-3

J3-2

SERIES FIELD

SHUNT FIELD

-

+

GENERATOR LEAD BLOCK

SHOWN AS VIEWED WITH

ENGINE IN THIS DIRECTION

-

-

+

+

INTERPOLE

COILS

SHUNT

FIELD

SERIES FIELD

J2 CONNECTOR IS NOT

USED ON THIS MACHINE

TYPICAL CURRENT DRAW

IS 40 +/- 3 AMPS

TYPICAL CURRENT

DRAW IS .98 AMPS

TYPICAL CURRENT

DRAW IS .56 AMPS

+

HOUR METER

8.8+/-.88 OHMS

TYPICAL CURRENT

DRAW IS 1.25 AMPS

12 11 10 9 8 7 6 5 4 3 2 1

P10

J5

SWITCH CLOSES

AT 6+/-2 PSI

SENDER OPERATION:

0 PSI -> 10+/-5 OHMS

40PSI -> 105+/-5 OHMS

80 PSI -> 187+/-5 OHMS

SHOWN IN "AUTO

IDLE" POSITION

FJW-5AR COIL PAIR:

22.5+/-.5 OHMS EACH

FLYBACK DIODE PREVENTS

VOLTAGE SPIKES IN SHUNT FIELD

FROM DAMAGING LOCAL/REMOTE

TOGGLE SWITCH WHEN SWITCHED

FDW-5M EXCITER COIL:

SHUNT COIL WINDINGS ARE 65+/-1.5 OHMS EACH

SERIES COIL WINDINGS ARE .143 +/-.005 OHMS EACH

SHOWN IN LOCAL

POSITION

3 TURNS

1 TURN

SENSOR GROUNDS LEAD TO

IDLER / ENGINE PROTECTION

BOARD ON SENSE OF WELD OR

AUXILIARY LOAD

Y

RHEOSTAT

W

G

X

REMOTE

RECEPTACLE

LOCAL / REMOTE

SWITCH

15 AMP

SWITCH CLOSES

AT 230

v

+/-6

v

F

SENDER OPERATION:

140

v

F -> 134+/-13.5 OHMS

194

v

F -> 51.2+/-4.3 OHMS

212

v

F -> 38.5+/-3 OHMS

P9

J8

4

6

5 3

1

2

64+/-6.4 OHMS MAX

THESE LEADS MUST BE ROUTED

THRU CURRENT SENSOR IN

SAME (CURRENT FLOW) DIRECTION

AS SHOWN

FUSE

BRUSH POSITION SHOWN AS

VIEWED FROM CONTROL PANEL

+

_

12 VOLT - NORMALLY OFF

SHOWN IN "OFF"

POSITION

53

50B

52

50

50A

51G

51

51A

59

57

56

53B

56A

54D

200

54

54B

212A

212B

61

58

58H

58A

70

841

844

N

U

67

602B

720

761

602

130

SELECTOR SWITCH

90-MIN

130-80

190-120

240-160

220-MAX

WELDING

GENERATOR

DC EXCITER

CCW

-40 TO 40 AMPS

AMMETER SHOWS FULL

DISCHARGE WHILE PRESSING

GLOW PLUG SWITCH

55 AMP / 12 VOLT

BAT

BAT

FLASH

GLOW PLUGS

N.C.

N.O.

ENGINE

SHUTDOWN

ENGINE

RUNNING

CR1

CR1

ENGINE PROTECTION AND

ALTERNATOR FLASHING DELAY

TIMER LOGIC

UPON RECIEVEING POWER,

CIRCUIT TO FLASH

ALTERNATOR IS OPENED AND

ENGINE PROTECTION IS

BYPASSED. AFTER TIME

DELAY, ALTERNATOR FLASHING

CIRCUIT IS CLOSED AND

ENGINE PORECTION IS

ENABLED. NOTE: AFTER TIME

DELAY WHEN ENGINE

PROTECTION IS ENABLED, IF

THE ENGINE IS NOT STARTED

THE OIL PRESSURE WILL BE

LOW AND THE MACHINE WILL

SHUT DOWN BECAUSE OF THE

ENGINE PROTECTION CIRCUIT.

12.6 VOLTS MIN

AT REST

14-14.5 VOLTS

WHILE RUNNING

ENGINE

PROTECTION

AND

ALTERNATOR

FLASHING

DELAY TIMER

(SEE BELOW

FOR LOGIC)

IDLER DELAY TIMER CIRUITS

Q2 ON FOR HIGH IDLE

INJECTION

PUMP

SOLENOID

FUEL PUMP

UNUSED

USED FOR TOROID IN AC

AUXILIARY MACHINES

SCHEMATIC L10826

FLYBACK DIODE

Q2

IDLE

SOLENOID

LEFT SIDEOF ENGINE(ASVIEWED

FROM CONTROL PANEL)

BACK OF MACHINE

(ASVIEWED FROM

CONTROL PANEL)

JUMPER PLUG IS

WIRE-TIED UPBEHIND

LOCAL / REMOTE

SWITCH ON RIGHT

SIDEOF MACHINE (AS

VIEWED FROM

CONTROL PANEL)

JUMPER PLUG IS FOR

CONNECTION TO WIRE

FEED MODULE

DC EXCITER USES RESIDUAL

MAGNETISM TO FLASH

LOCATED BEHIND UPPER PORTION OF CONTROL PANEL

LOCATED BEHIND UPPER

PORTION OF CONTROL PANEL

TYPICAL OCV (WARM MACHINE):

88-98 VOLTS AT MAX RHEOSTAT

47-60 VOLTS AT MIN RHEOSTAT

DRIVER

CIRCUITS

12 VOLT SUPPLY

JUMPER PLUG IS

WIRE-TIED UPBEHIND

LOCAL / REMOTE

SWITCH ON RIGHT

SIDEOF MACHINE (AS

VIEWED FROM

CONTROL PANEL)

SENDER IS APPROX.

500 OHMS AT 70

v

F

K924-5 REMOTE CONTROL

(OPTIONAL)

RHEOSTAT

REMOTE CONTROL BOX

25+/-1.25 OHMS EACH

64+/-6.4 OHMS MAX

CCW

Y

W

G

X

REMOTE CONTROL PLUG

3 AMP CURRENT LIMIT

NO OVER

CURRENT

PROTECTION

G-7

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.