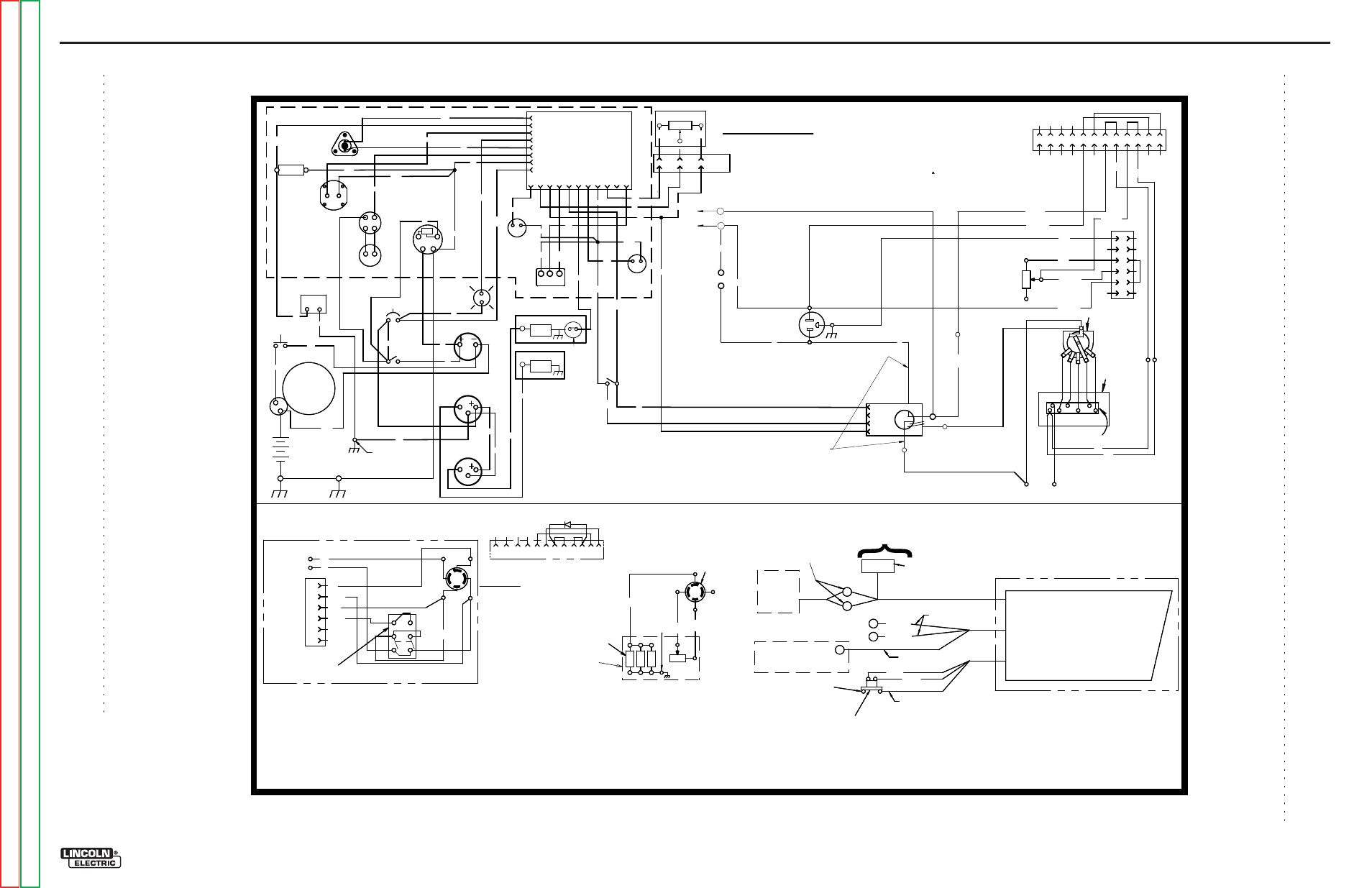

Pipeliner 200g wiring diagram, Wire feed module (optional) wire feed module, K924-4 remote control (optional) – Lincoln Electric PIPELINER 200 User Manual

Page 136: Electrical diagrams

ELECTRICAL DIAGRAMS

G-2

PIPELINER® 200

WIRING DIAGRAM - CODE 10660 - (L11402)

A

5 4 3 2 1

NEGATIVE

SELECTOR

SWITCH

WELDER

LEAD BLOCK

42

602A

U

1

2

3

4

5

6

600A

41

GENERATOR

N

600B

610

602B

J5

P9

J8

POSITIVE

P10

N

U

RHEOSTAT

(CC-)

(CC+) & (CV+ WITH W.F.M.)

Y

B

W

G

PLUG FOR

REMOTE CONTROL

POTENTIOMETER

B

*

P8

1

2

3

4

5

6

X

41

600

42

602

W

R

BELOW

SEE

*

SWITCH FOR LOCAL OR REMOTE CONTROL

SHOWN IN LOCAL POSITION.

REMOTE CONTROL RECEPTACLE & SWITCH

X

Y

#2 HEAVY LEAD

WIRE FEED MODULE (OPTIONAL)

WIRE FEED

MODULE

W.F.M.

CONTROL

PANEL

NEG.

POS.

OUTPUT TERMINALS

CONNECT TO POS. & NEG.

{

CONNECT TO NEG.

BRUSH HOLDER

608

609

#2 HEAVY LEAD

#8 LEAD

NEGATIVE CV

OUTPUT TERMINAL

PANEL

MACHINE MUST NOT BE RUNNING

WHEN MAKING THESE CONNECTIONS.

ON MACHINE, REMOVE PLUG "P10" FROM CONNECTOR "J5".

CONNECT PLUG "P5" ON W.F.M. TO CONNECTOR "J5" ON MACHINE.

PLUG

(P5)

200 AMP

THERMOSTAT

ASSEMBLY

INLINE

CONNECTORS

REMOTE CONTROL

POTENTIOMETER BOX

L11402

PIPELINER 200G WIRING DIAGRAM

CONNECT

TO CASE

'

NEUTRAL BONDED TO FRAME

NEUTRE RACCORDE AU BATI

A

K924-4 REMOTE CONTROL (OPTIONAL)

WITH MACHINE NOT RUNNING

, REMOVE PLUG "P9" ON MACHINE FROM CONNECTOR "J8".

THEN CONNECT PLUG "P8" ON REMOTE CONTROL TO CONNECTOR "J8" ON MACHINE.

CAUTION: DAMAGE CAN OCCUR

TO THE REMOTE CONTROL

SWITCH IF IT IS USED

WITHOUT THE "P11" PLUG

FEED MODULE INSTALLED.

IF A WIRE FEED MODULE IS INSTALLED, WITH THE MACHINE OFF, DISPOSE OF THE

UNCONNECTED PLUG "P10" (IF ONE IS ON THE MACHINE) FASTEN THE NEW PLUG "P11"

NEARBY, LEAVING IT UNCONNECTED.

IF NO WIRE FEED MODULE

IS INSTALLED, WITH THE MACHINE OFF, DISCONNECT PLUG "P10"

ON THE MACHINE FROM CONNECTOR "J5". CONNECT PLUG "P11" FROM THE REMOTE CONTROL

KIT TO CONNECTOR "J5" ON THE MACHINE.

SEE BELOW

SHOWN AS VIEWED FROM REAR.

CONTROL PANEL COMPONENTS

1

2

3

4

5

6

7

8

9

10

11

12

*

*

*

*

CURRENT

SENSOR

CAUTION

: DAMAGE CAN OCCUR TO THE REMOTE CONTROL SWITCH IF IT IS USED

WITHOUT THE "P11" PLUG INSTALLED OR A WIRE FEED MODULE INSTALLED.

ON PIPELINER 200G MACHINES, CONNECT RED AND BLACK LEADS ON REMOTE TO

E

TO

EXCITER

OUTPUT

RED AND BLACK LEADS ON MACHINE.

R

FOR

REMOTE

OPTION

B

W

3

2

1

4

RESISTORS

INSTALLED OR A WIRE

1

2

3

4

5

6

7

8

9

10

11

12

P11

E

BELOW

SEE

*

RECEPTACLE

B

ELECTRICAL SYMBOLS

LEAD COLOR CODE

PER E1537

B - BLACK

G - GREEN

N - BROWN

R - RED

U - BLUE

W - WHITE

Y - YELLOW

+

-

+

84

-

51

60

EXC

+

70

S

B

+

GROUND

TO BASE

GROUND

TO ENGINE

3

4

5

14

61

62

15

19

ZENITH THROTTLE

BODY

CONTROLLER

71

72

82

81

76

74

73

83

99E

78

99

80

89

21

22

+

-

-

WHITE

CONNECTOR

BLACK

CONNECTOR

11

9

8

5

4

3

1

17

13

-

+

96

99D

87A

WATER

TEMP.

SENSOR

A B

AIR

TEMP.

SENSOR

95

CB5

A B C

93

#

INJECTOR

THROTTLE PLATE

MOTOR

A

B

92

91

90

97

97A

99B

99C

67

2

MAP SENSOR

12

COIL

DISTRIBUTOR

IDLER

SWITCH

ALTERNATOR

IGNITION

SWITCH

STARTER

MOTOR

ENGINE

HOUR METER

ENGINE

FAILURE

LAMP

START

WATER TEMP.

GAUGE

S

A B

94

FUEL PUMP

77

OIL PRESS.

GAUGE

S

CONTROL PA NEL

GROU ND SCR EW

69

45

R

G

87

99A

97B

97C

50

87B

10 K

RPM CONTROL

4

3

1

2

3

2

1

AMMETER

SENSOR

WATER TEMP. SENDER

SENSOR

OIL PRESSURE SWITCH & SENSOR

SWITCH

WK

G

PARTS SUPPLIED

WITH ENGINE

610B

THESE LEADS MUST BE ROUTED THRU

CURRENT SENSOR IN THE SAME (CURRENT FLOW)

DIRECTION AS SHOWN.

G-2

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The wiring diagram specific to your code is pasted inside one of the enclosure panels of your machine.