Start-up – Lochinvar Kight XL 400-801 User Manual

Page 34

34

7

Start-up

Outdoor Knight XL Installation & Operation

Manual

Check for gas leaks

Before starting the boiler, and during

initial operation, smell near the fl oor and

around the boiler for gas odorant or any

unusual odor. Remove the top access

panel and smell the interior of the boiler

enclosure. Do not proceed with startup

if there is any indication of a gas leak.

Use an approved leak detection solution.

Repair any leaks at once.

DO NOT adjust gas valve outlet pressure.

The gas valve is factory set for the correct

outlet pressure. This setting is suitable

for natural gas and propane, requiring

no fi

eld adjustment. Attempting to

alter the gas valve outlet pressure could

result in damage to the valve, causing

potential severe personal injury, death, or

substantial property damage.

Propane boilers only – Your propane

supplier mixes an odorant with the propane

to make its presence detectable. In some

instances, the odorant can fade, and the

gas may no longer have an odor. Before

startup (and periodically thereafter), have

the propane supplier verify the correct

odorant level in the gas.

Check thermostat circuit(s)

1. Disconnect the two external wires connected to each

of the heat/loop demand terminals on the connection

board.

2. Connect a voltmeter across these two incoming wires.

Close each thermostat, zone valve, and relay in the

external circuit one at a time and check the voltmeter

reading across the incoming wires.

3. There should NEVER be a voltage reading.

4. If a voltage does occur under any condition, check and

correct the external wiring. (This is a common problem

when using 3-wire zone valves.)

5. Once the external thermostat circuit wiring is checked and

corrected if necessary, reconnect the external thermostat

circuit wires to the connection board. Allow the boiler to

cycle.

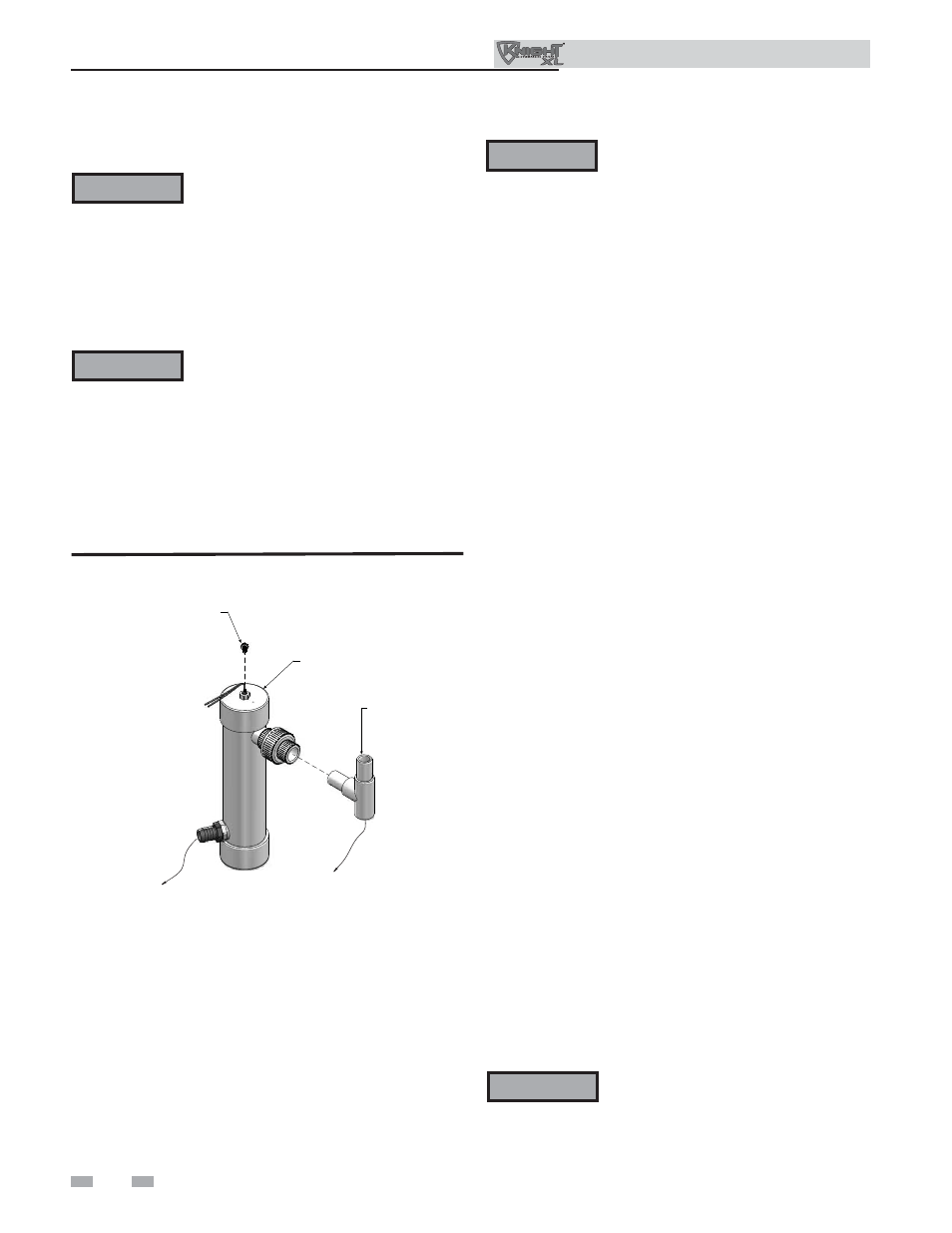

Inspect/fi ll condensate system

Inspect/check condensate lines and fi ttings

1. Inspect the condensate drain line, condensate PVC

fi ttings and condensate trap.

Fill condensate trap with water

1. Remove the PVC cap retaining screw from the PVC cap

(FIG. 7-1).

2. Remove the 2 inch PVC cap with the switch located at the

top of the trap (FIG. 7-1).

3. Fill with fresh water until the water begins to pour out of

the drain.

4. Replace the cap. Press the cap onto the trap until the cap

makes contact with the drain.

5. Replace the retaining screw.

The condensate trap (FIG. 7-1) must be

fi lled with water during all times of boiler

operation to avoid fl ue gas emission from

the condensate drain line. Failure to fi ll

the trap could result in severe personal

injury or death.

PVC TEE ASSEMBLY

(FACTORY SUPPLIED)

TO FLOOR

DRAIN

2” PVC CAP WITH

BLOCKED DRAIN SWITCH

RETAINING

SCREW

CONDENSATE FROM

HEAT EXCHANGER

Figure 7-1 Condensate Trap

ƽ WARNING

ƽ WARNING

ƽ WARNING

ƽ WARNING