Hydronic piping – Lochinvar Kight XL 400-801 User Manual

Page 15

15

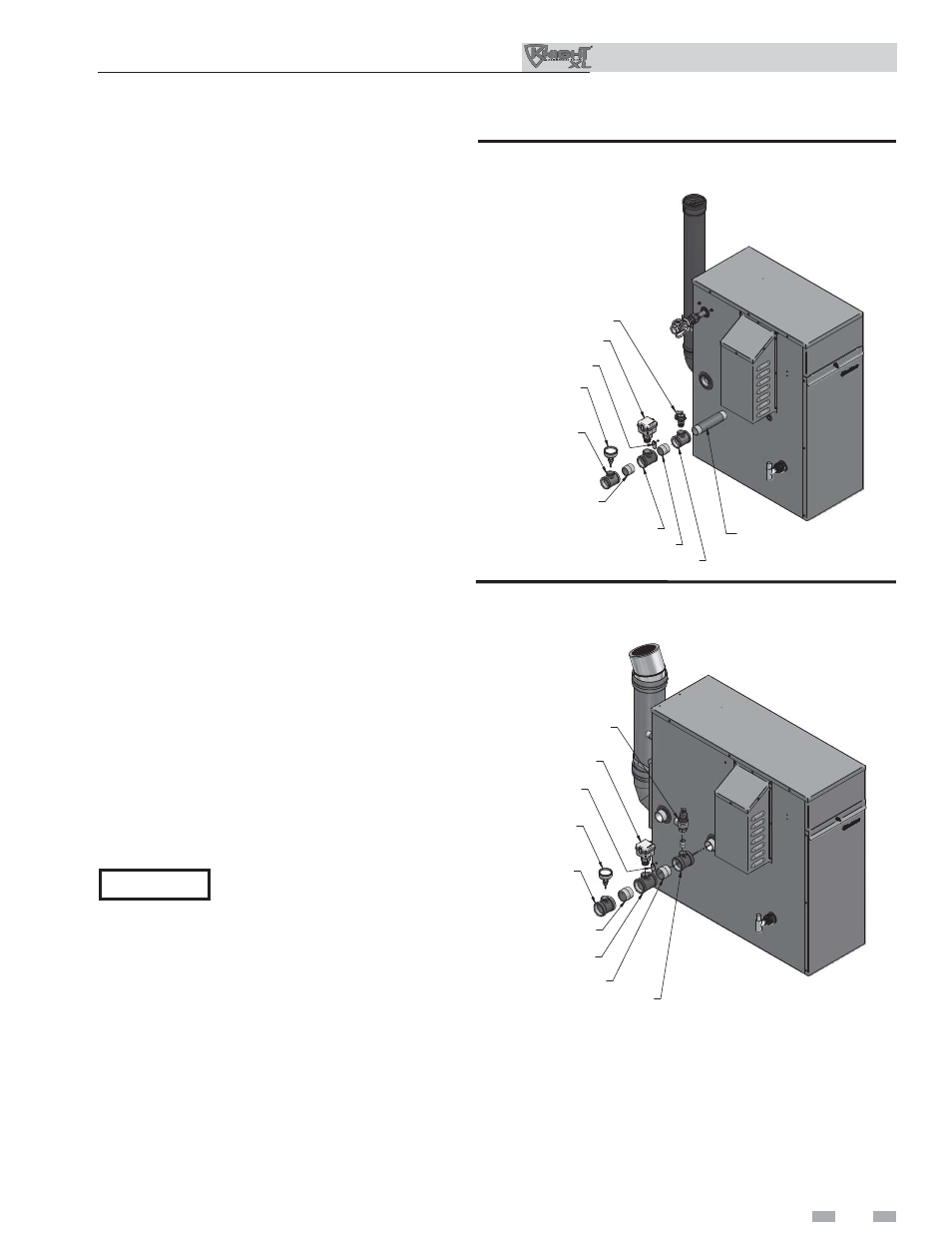

RELIEF VALVE

FLOW SWITCH

PADDLE

TEMPERATURE &

PRESSURE GAUGE

TEE WITH FITTING

(FIELD PROVIDED)

CLOSE NIPPLE

(FIELD PROVIDED)

TEE WITH 1" FITTING

ON TOP

CLOSE NIPPLE

TEE WITH 3/4"

FITTING ON TOP

IMG00389

NOTICE

Be sure to install the fl ow switch so

that the arrow on the fl ow switch is

pointing in the direction of the fl ow

(see FIG. 3-3).

Figure 3-2 Flow Switch, Relief Valve and Temperature and

Pressure Gauge Installation_Models 601 - 801

Flow switch, relief valve and temperature

and pressure gauge installation

Basic steps are listed below to guide you through the

installation of the fl ow switch, relief valve, and temperature

and pressure gauge provided with the unit.

1. For Models 400 - 501 install the close nipple on the

outlet connection of the heat exchanger. Install the tee

with the 3/4 inch fi tting positioned vertically and on

the top as shown in FIG. 3-1. For Models 601 - 801

install the tee directly to the outlet connection of the

heat exchanger with the 3/4 inch fi tting positioned

vertically and on the top (see FIG. 3-2).

2. For Models 701 - 801 install the 3/4 inch close nipple

in the tee. Install the relief valve on the 3/4 inch close

nipple (FIG. 3-2). For Models 400 - 601 install the

relief valve directly into the 3/4 inch fi tting on the tee

(FIG.

3-1).

3. Install the close nipple on the downstream side of

the relief valve tee (FIG. 3-1).

4. Install the tee with the 1 inch fi tting positioned

vertically and on the top (FIG. 3-1).

5. Attach paddle #3 to the fl ow switch per the

manufacturer’s instructions.

6. Install the assembled fl ow switch into the 1 inch fi tting

of the tee installed in Step 4 (see FIG. 3-1).

7. Install

a

fi eld provided close nipple on the downstream

side of the fl ow switch (see FIG.’s 3-1 and 3-2).

8. Install

a

fi eld provided tee with the gauge fi tting

positioned vertically and on the top (FIG.’s 3-1 and

3-2)

9. Install the temperature and pressure gauge provided

with the unit into the top fi tting of the tee (a bushing

may be necessary) installed in Step 8 (FIG.’s 3-1 and

3-2).

RELIEF VALVE

FLOW SWITCH

PADDLE

TEMPERATURE &

PRESSURE GAUGE

TEE WITH FITTING

ON TOP

(FIELD PROVIDED)

CLOSE NIPPLE

(FIELD PROVIDED)

TEE WITH 1" FITTING ON TOP

CLOSE NIPPLE

TEE WITH 3/4"

FITTING ON TOP

8' NIPPLE

(REQUIRED FOR MODELS 400 - 701)

IMG00390

Figure 3-1 Flow Switch, Relief Valve and Temperature and

Pressure Gauge Installation_Models 400 - 501

3

Hydronic piping

(continued)

Outdoor Knight XL Installation & Operation

Manual