Engine top end, Air suction valve inspection, Valve clearance inspection – Kawasaki STX-15F User Manual

Page 39: Special tool

PERIODIC MAINTENANCE 2-15

Periodic Maintenance Procedures

Engine Top End

Air Suction Valve Inspection

•

Remove the air suction valve (see Engine Top End chap-

ter).

•

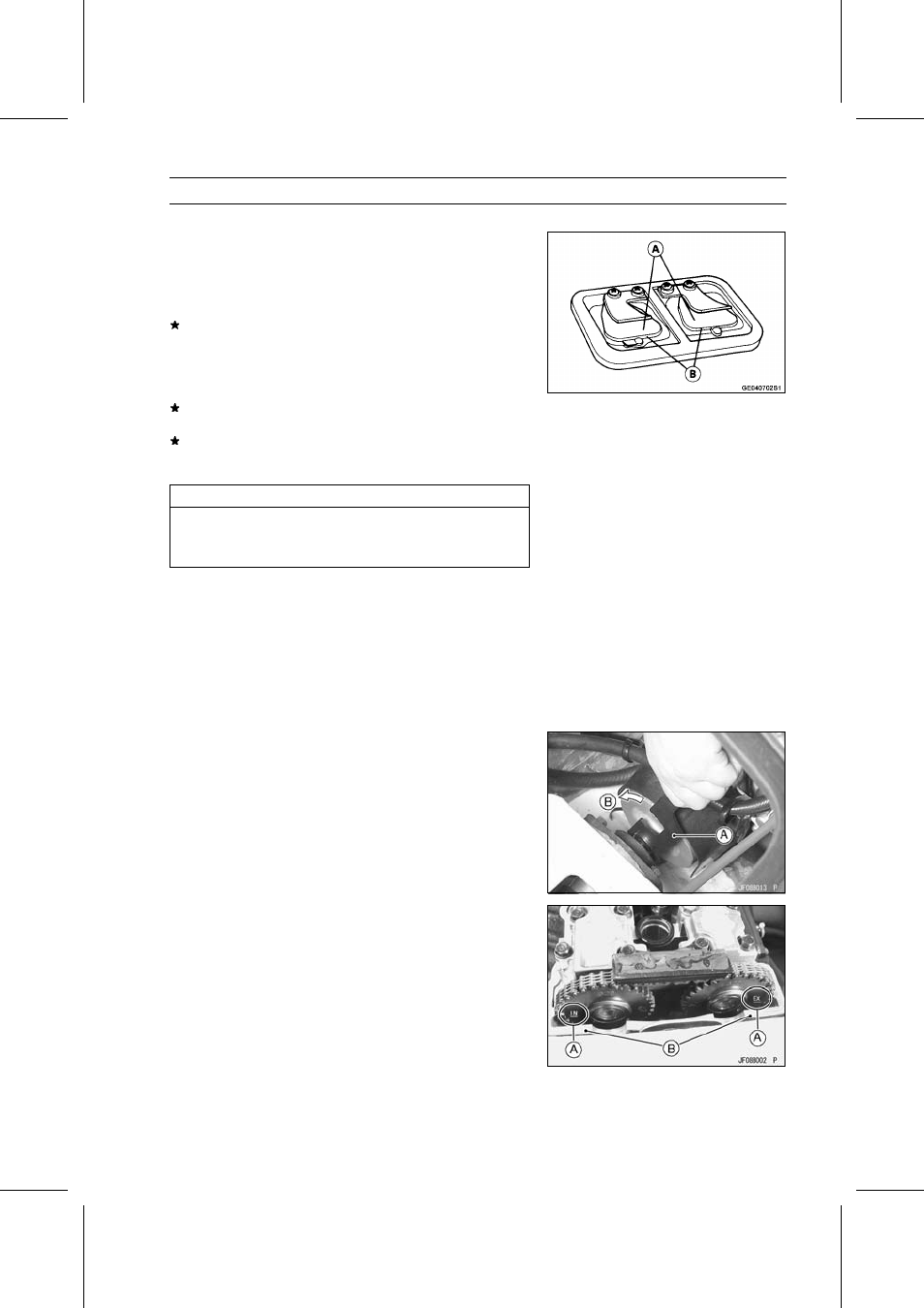

Visually inspect the reeds [A] for cracks, folds, warps,

heat damage, or other damage.

If there is any doubt as to the condition of the reed, replace

the air suction valve as an assembly.

•

Check the reed contact areas [B] of the valve holder for

grooves, scratches, any signs of separation from the

holder, or heat damage.

If there is any doubt as to the condition of the reed contact

areas, replace the air suction valve as an assembly.

If any carbon or other foreign particles have accumulated

between the reed and the reed contact area, wash the

valve assembly with a high-flash point solvent.

CAUTION

Do not scrape off the deposits with a scraper as this

could damage the rubber, requiring replacement of

the suction valve assembly.

Valve Clearance Inspection

NOTE

○

Valve clearance must be checked and adjusted when

the engine is cold (at room temperature).

•

Remove:

Seat (see Hull/Engine Hood chapter)

Cylinder Head Cover (see Engine Top End chapter)

•

Position the crankshaft at #1, #4 piston TDC as follows.

○

Using the shaft wrench [A], turn the crankshaft counter-

clockwise [B] and set the crankshaft at #1, 4 piston TDC.

Special Tool - Shaft Wrench: 57001-1551

○

The timing marks [A] must be aligned with the cylinder

head upper surface [B] as shown.