Crankshaft sensor resistance, Sealant, Torque – Kawasaki STX-15F User Manual

Page 364: Timing rotor removal, Special tools, Timing rotor installation, Crankshaft sensor inspection

14-38 ELECTRICAL SYSTEM

Ignition System

•

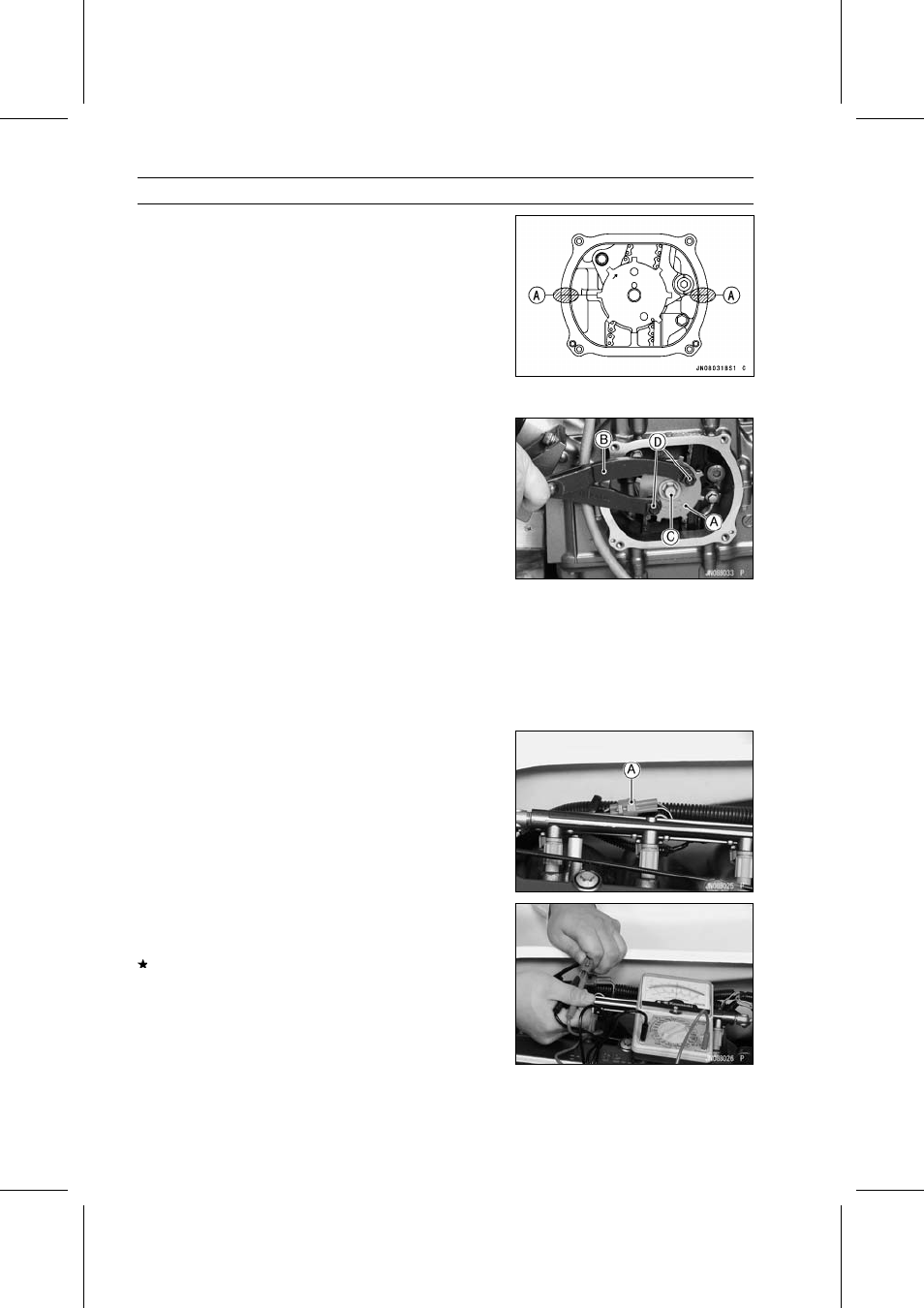

Apply grease to the O-ring and fit it in the groove of the

sensor cover.

•

Apply silicone sealant [A] to the crankcase halves mating

surface on the right and left sides of the crankshaft sensor

mount.

Sealant - Kawasaki Bond (Silicone Sealant): 56019-120

•

Install the crankshaft sensor cover.

Torque - Crankshaft Sensor Cover Bolts: 7.8 N·m (0.80

kgf·m, 69 in·lb)

•

Install the Engine (see Engine Removal/Installation chap-

ter).

Timing Rotor Removal

•

Remove the engine (see Engine Removal).

•

Remove the crankshaft sensor cover (see Crankshaft

Sensor Removal).

•

Remove the timing rotor [A].

○

Holding the timing rotor with the flywheel and pulley holder

[B] and unscrew the bolt [C].

Special Tools - Flywheel & Pulley Holder: 57001-1605

Flywheel and Pulley Holder Adapter: 57001

-1547 [D]

Timing Rotor Installation

•

Fit the rotor to the crankshaft.

•

Apply a non-permanent locking agent to the rotor bolt.

•

Tighten the rotor bolt.

Torque - Timing Rotor Bolt: 20 N·m (2.0 kgf·m, 14 ft·lb)

•

Install the crankshaft sensor cover (see Crankshaft Sen-

sor Cover Installation).

Crankshaft Sensor Inspection

•

Remove:

Seat (see Hull/Engine Hood chapter)

•

Disconnect the 2-pin crankshaft sensor leads connector

(Blue) [A].

•

Set the hand tester to the × 100 Ω range, zero it, and

connect it to the crankshaft sensor lead terminals (G and

BL) in the connector.

If there is more resistance than the specified value, the

sensor has an open lead and must be replaced. Much

less than this resistance means the sensor is shorted, and

must be replaced.

Crankshaft Sensor Resistance

Standard: 408

∼

612 Ω