Troubleshooting, Pressure w asher t roub leshooting guide – Shark HPB-3520 User Manual

Page 16

97-6068, 97-6131 • REV. 3/06

PRESSURE

W

ASHER

T

roub

leshooting Guide

16

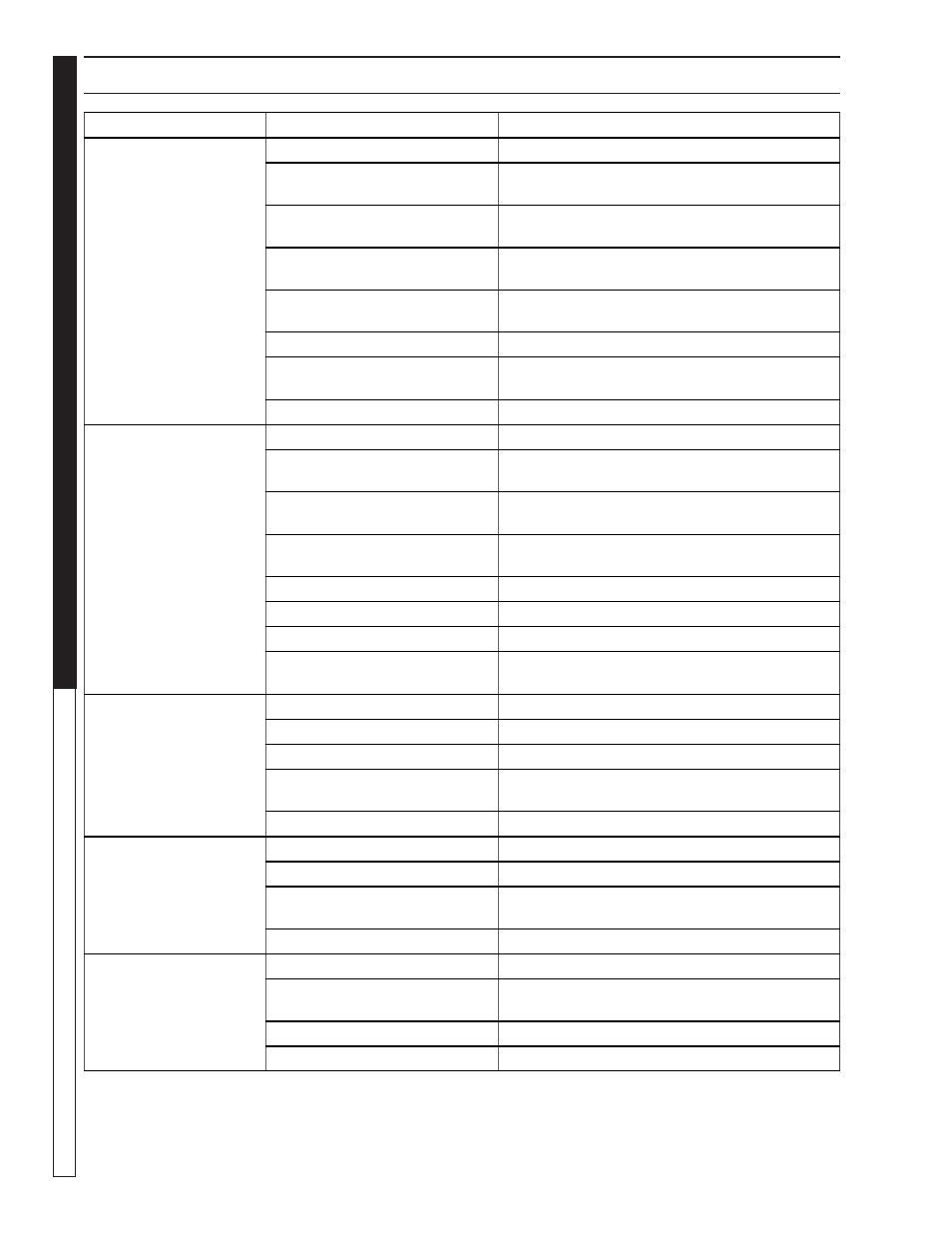

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

LOW OPERATING

PRESSURE

Faulty pressure gauge

Install new gauge.

Insufficient water supply

Use larger garden hose; clean filter washer at water

inlet.

Old, worn or incorrect spray nozzle Match nozzle number to machine and/or replace

with new nozzle.

Plumbing or hose leak

Check plumbing system for leaks. Retape leaks with

teflon tape.

Faulty or misadjusted unloader

valve (where applicable)

Adjust unloader for proper pressure. Install repair kit

when needed.

Worn packing in pump

Install new packing kit.

Fouled or dirty inlet or discharge

valves in pump

Clean inlet or discharge valves.

Worn inlet or discharge valves

Replace with valve kit.

DETERGENT NOT

DRAWING

Air leak

Tighten all clamps. Check detergent lines for holes.

Valve in the injector head may be

blocked, dirty or damaged

Clean or replace valve in injector.

Filler screen on detergent suction

hose plugged

Clean or replace.

Dried up detergent plugging

metering valve

Disassemble and clean thoroughly.

High viscosity of detergent

Dilute detergent to specifications.

Hole in detergent line(s)

Repair hole.

Low detergent level

Add detergent if needed.

Discharge water temperature

above 180

o

F.

Lower discharge water temperature.

PUMP RUNNING

NORMALLY BUT

PRESSURE LOW ON

INSTALLATION

Pump sucking air

Check water supply and possibility of air seepage.

Valves sticking

Check and clean or replace if necessary.

Unloader valve seat faulty

Check and replace if necessary.

Nozzle incorrectly sized

Check and replace if necessary (See serial plate for

proper size).

Worn piston packing

Check and replace in necessary.

FLUCTUATING

PRESSURE

Valves worn

Check and replace if necessary.

Blockage in valve

Check and replace if necessary.

Pump sucking air

Check water supply and air seepage at joints in

suction line.

Worn piston packing

Check and replace if necessary.

PUMP NOISY

Air in suction line

Check water supply and connections on suction line.

Broken or weak inlet or discharge

valve springs

Check and replace if necessary.

Excessive matter in valves

Check and clean if necessary.

Worn bearings

Check and replace if necessary.