Installation instructions – Siemens SED2 VFD Electronic Bypass Option 125-3208 User Manual

Page 25

Installation Instructions

Siemens Building Technologies, Inc.

17

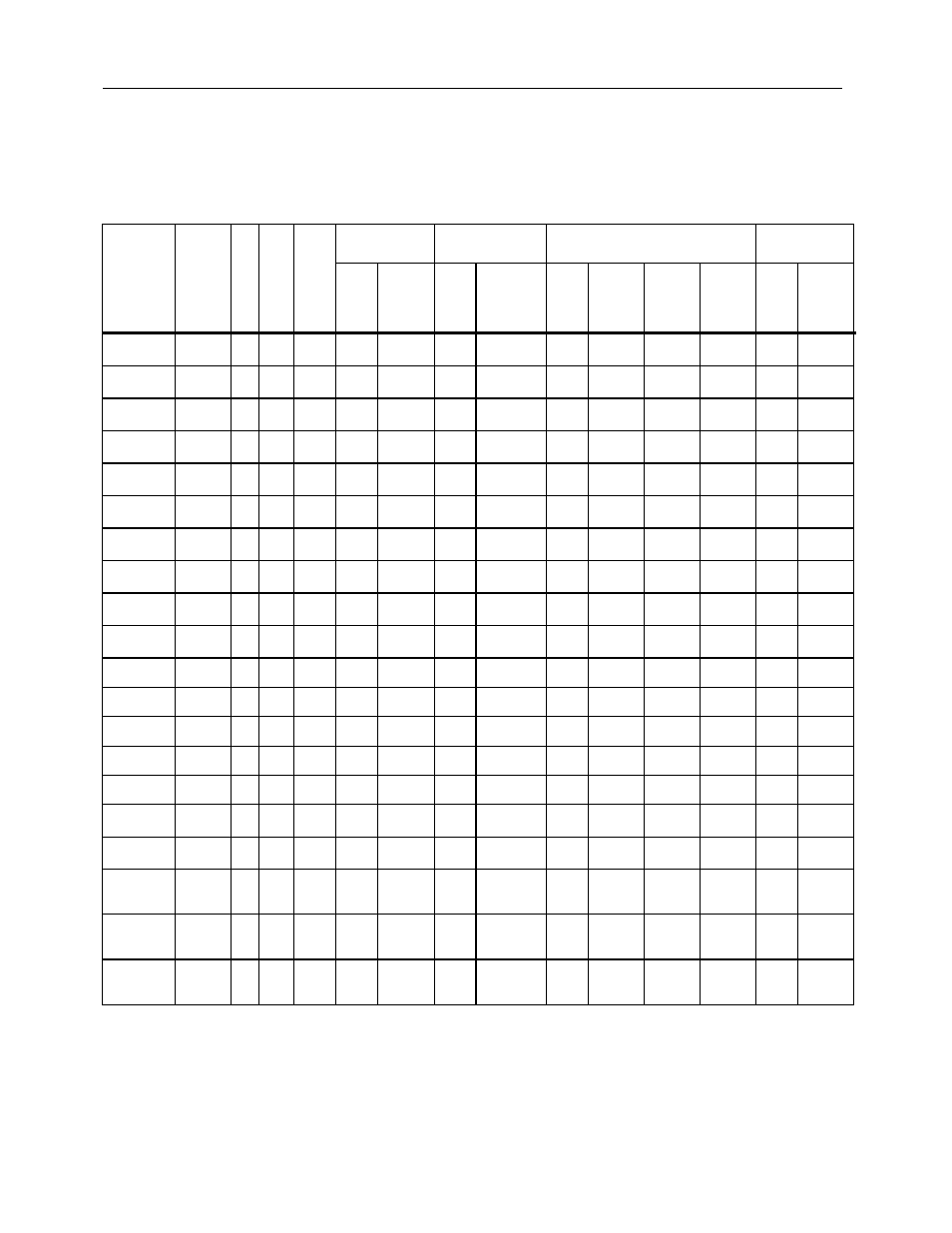

Table 3. Wire Sizes and Tightening Torques for E-Bypass with 380V to 480V Drive.

Circuit Breaker

Disconnect

Switch

Overload Ground

Lug

Part

Number

Bypass

Frame

Size

HP kW Amps

Wire

Size *

Torque,

lb-in

(Nm)

Wire

Size *

Torque,

lb-in

(Nm)

Wire

Size *

Torque,

lb-in

(Nm)

Range,

Amps

Max

Backup

Fuse,

Amps

Wire

Size*

Torque,

lb-in

(Nm)

VBE30.5---- A 0.5

0.37

1.1

14-10

Cu

32 (3.6)

18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(8 - 1.2)

.7 - 1.0

4 14-2

35

(4)

VBE30.7---- A 0.7

0.55

1.6

14-10

Cu

32 (3.6)

18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(8 - 1.2)

1.1 - 1.6

6 14-2

35

(4)

VBE31.0---- A 1.0

0.75

2.1

14-10

Cu

32 (3.6)

18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(8 - 1.2)

1.4 - 2.0

8 14-2

35

(4)

VBE31.5---- A 1.5

1.1

3.0

14-10

Cu

32 (3.6)

18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(8 - 1.2)

2.2 - 3.2

12 14-2

35

(4)

VBE32.0---- A 2.0

1.5

3.4

14-10

Cu

32 (3.6)

18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(8 - 1.2)

2.8 - 4

16 14-2

35

(4)

VBE33.0---- B 3.0

2.2

4.8

14-10

Cu

32 (3.6)

18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(8 - 1.2)

3.5 - 5

20 14-2

35

(4)

VBE35.0---- B 5.0

4.0

7.6

14-10

Cu

32 (3.6)

18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(.8 - 1.2)

7 - 10

40 14-2

35

(4)

VBE37.5---- C 7.5

5.5

11

14-10

Cu

32 (3.6)

18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(8 - 1.2)

9 - 12

45 14-2

35

(4)

VBE310---- C 10

7.5

14

14-10

Cu

32 (3.6)

18-10

13 to17

(1.5 - 1.7)

14-10

18 - 22

(2 - 2.5)

11 - 16

60 14-2

35

(4)

VBE315---- C 15

11.0

21

14-10

Cu

20 - 60

(2.2 - 6.8)

14-8

17 - 22

(1.9 - 2.5)

14-10

18 - 22

(2 - 2.5)

17 - 22

80 14-2

35

(4)

VBE320---- C 20

15.0

27

10-1/0

Cu

20 - 60

(2.2 - 6.8)

14-8

17 - 22

(1.9 - 2.5)

18-3

27 - 40

(3.1 - 4.5)

22 - 32

125 14-2 35

(4)

VBE325---- D 25

18.5

34

10-1/0

Cu

20 - 60

(2.2 - 6.8)

14-6

22 - 27

(2.5 - 3.1)

18-3

27 - 40

(3.1 - 4.5)

28 - 40

150 14-2 35

(4)

VBE330---- D 30

22.0

40

10-1/0

Cu

20 - 60

(2.2 - 6.8)

14-6

22 - 27

(2.5 - 3.1)

18-3

27 - 40

(3.1 - 4.5)

28 - 40

150 14-2 35

(4)

VBE340---- D 40

30.0

52

10-1/0

Cu

20 - 60

(2.2 - 6.8)

14-6

22 - 27

(2.5 - 3.1)

18-3

27 - 40

(3.1 - 4.5)

40 - 50

200 14-2 35

(4)

VBE350---- E 50

37.0

65

10-1/0

Cu

20 - 60

(2.2 - 6.8)

12-1

22 - 27

(2.5 - 3.1)

10-1/0

36 - 53

(4.1 - 6)

57 - 75

300 14-2 35

(4)

VBE360---- E 60

45.0

77

3-3/0

Cu

80 (9)

12-1

22 - 27

(2.5 - 3.1)

10-1/0

36 - 53

(4.1 - 6)

70 - 90

350 14-2 35

(4)

VBE375---- F 75

55.0

96

3-3/0

Cu

80 (9)

12-1

22 - 27

(2.5 - 3.1)

10-1/0

36 - 53

(4.1 - 6)

80 - 100

400 14-2/0

50

(5.6)

VBE3100---- F 100

75.0

124

6 - 350

kcmil

Cu

120 - 275

(14 - 31.1)

6 - 350

kcmil

120 - 275

(13.5 - 31.1)

6-3/0

124 - 210

(14 - 23.7)

50 - 200

800

14-2/0

50 (5.6)

VBE3125---- F 125

90.0

156

6 - 350

kcmil

Cu

120 - 275

(14 - 31.1)

6 - 350

kcmil

120 - 275

(13.5 - 31.1)

6-3/0

124 - 210

(14 - 23.7)

50 - 200

800

14-2/0

50 (5.6)

VBE3125--

HA

F —

90.0

178

6 - 350

kcmil

Cu

120 - 275

(14 - 31.1)

6 - 350

kcmil

120 - 275

(13.5 - 31.1)

6-3/0

124 - 210

(14 - 23.7) 50 - 200

800

14-2/0

50 (5.6)

* Wire size is AWG unless noted otherwise. Use Copper (Cu) wire that is rated 167°F (75°C) minimum

600 Vac.