Warning, Operation – John Deere rhino pd54 User Manual

Page 24

- 24 -

3. OPERATION

For satisfactory operation, the following oil

conditions apply:

1. Accurate level readings can be checked

only when the fluid is cold.

2. If the natural color of the fluid has become black

or milky, it is possible that an overheating or

water contaminant problem exists.

3. Do not mix hydraulic fluids. Mobil 424 is

recommended for the hydraulic system.

CAUTION: After a new unit has run 5 hours, the

oil filter should be changed. This is to rid the

system of any trapped contamination from the wear-

in of the parts. Refer to Maintenance for hydraulic

filter change.

3.7 ENGINE COOLANT

CHECK COOLING SYSTEM CAREFULLY.

EXPLOSIVE RELEASE OF FLUIDS FROM

PRESSURIZED COOLING SYSTEM CAN

CAUSE SERIOUS BURNS.

To check coolant level:

1. Shut off engine, allow to cool.

2. Only remove filler cap when cool enough to

touch with bare hands. Slowly loosen cap to

first stop to relieve pressure before removing

completely.

3. Remove cap, coolant level should just touch the

bottom of radiator filler neck. If coolant is

required, see Adding Coolant in the

Maintenance section of this manual.

IMPORTANT: Do not overfill radiator. Refer to

Coolant Maintenance if additional coolant is

required. Never pour cold liquid into a hot

engine, as it may crack cylinder head or block.

DO NOT operate engine without coolant for even

a few minutes. If coolant leaks or abnormal

temperature is detected, contact a service

technician immediately.

NOTE:It is normal for a small amount of leakage to

occur as the engine cools down and parts contract.

Excessive coolant leakage may indicate the need to

replace the water pump seal. Contact your engine

distributor or servicing dealer for repairs.

3.8 VISUAL INSPECTION

Make a thorough inspection of the engine compartment

daily. Look for oil or coolant leaks, worn fan belt,

loose connections and trash build-up. Remove trash

build-up and have repairs made as needed if leaks are

found.

NOTE:Wipe all fittings, caps, and plugs before

performing any maintenance to reduce the chance of

system contamination.

Air intake system hoses and connections for

cracks and loose clamps.

Fan belt for cracks, breaks, or other damage.

Water pump for coolant leaks.

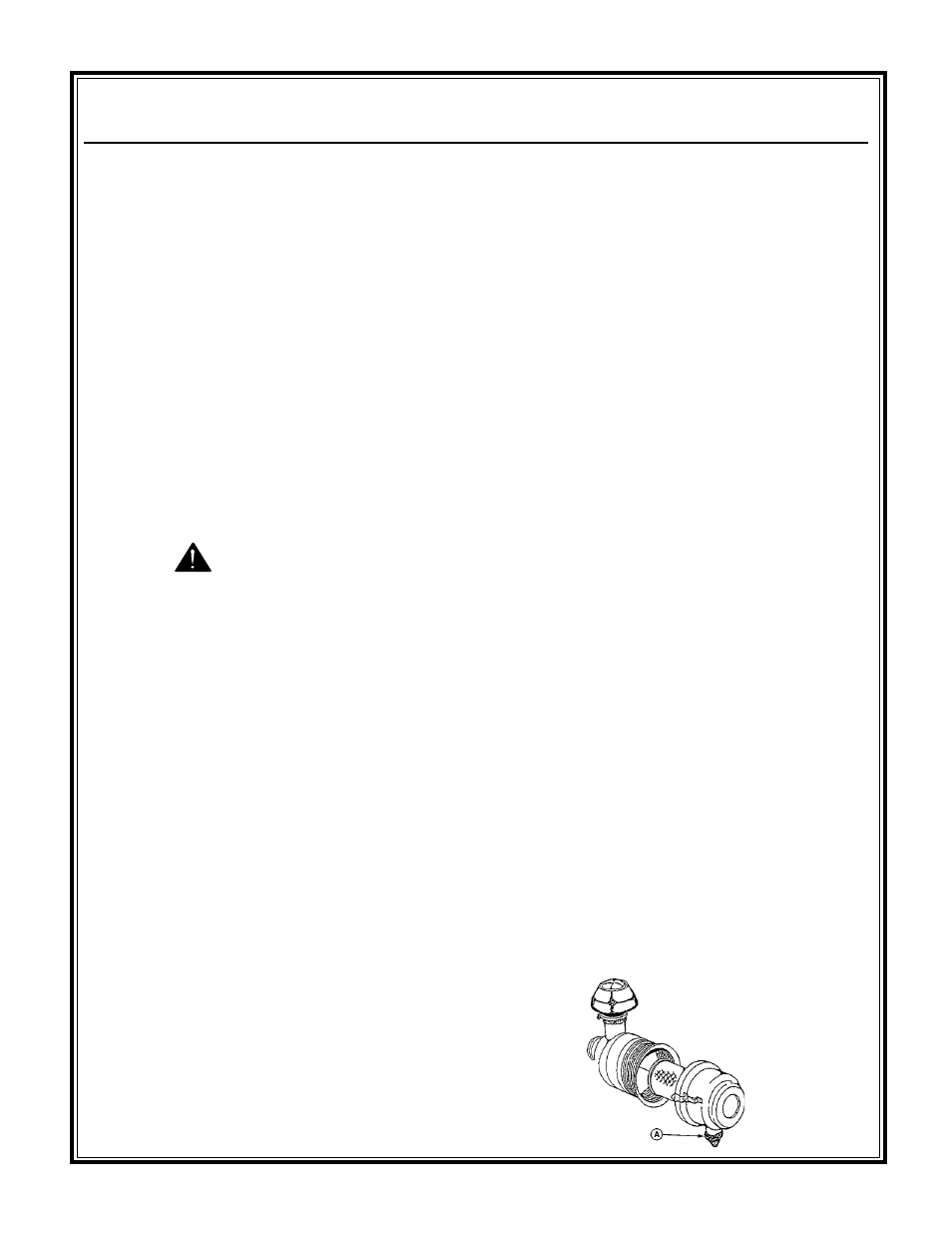

3.9 AIR CLEANER

IMPORTANT: The air intake system must not leak.

Any leak, no matter how small, may result in engine

failure due to abrasive dirt and dust entering the

intake system.

1. Inspect all intake hoses (piping) for cracks.

2. Check clamps on piping which connect the air

cleaner and engine.

3. Squeeze dust unloader valve (A) on air cleaner

assembly to remove dust deposits. If clogged,

remove and clean the dust unloader valve. Replace

if damaged.

IMPORTANT: Do not operate engine without the

dust unloader valve.

WARNING