MK Diamond Products MK-370EXP User Manual

Page 35

35

Lower

Screw

No gaps between

Blade and Square

Rotate Knob Counter-

clockwise to loosen

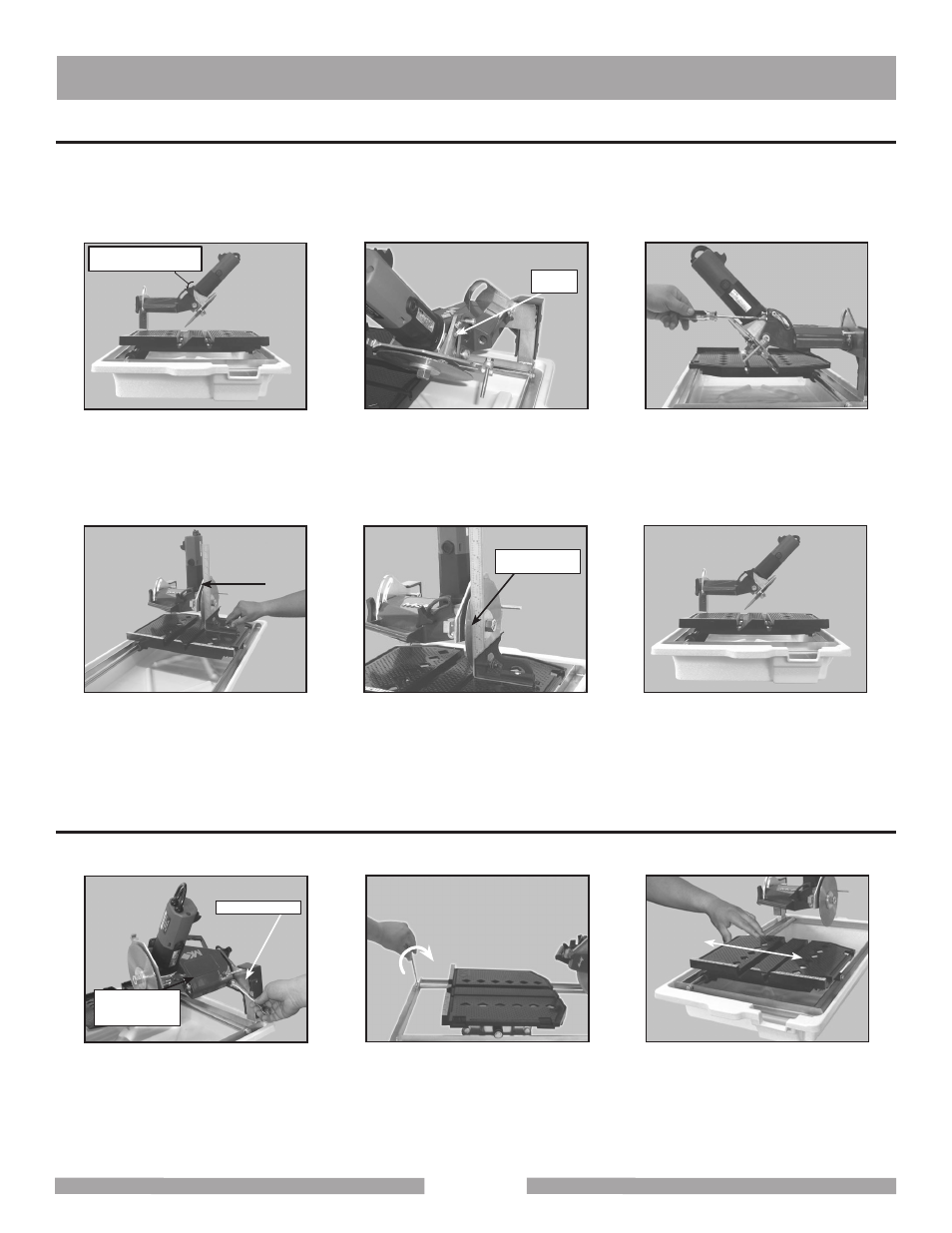

ALIGNMENT SCREW, 90° VERIFICATION

NOTES: If the blade is misaligned following this alignment procedure, return the saw to MK Diamond for

repair. The Diamond Blade must be removed and reinstalled when removing the Blade Guard.

90º- alignment verification will ensure that the blade will cut the tile straight up and down and not at an angle.

(B)

Locate the 90°

Adjustment Screw

(A)

Position the Cutting Head

to the 45° Cutting Angle

(C)

Rotate 90° Adjustment Screw

clockwise or counter-clockwise

to realign Cutting Head

(E)

Verify the Diamond Blade

is Square to the Movable

Cutting Table

(D)

Position the Square on

Movable Cutting Table

against the Diamond Blade

(F)

Repeat Steps A to E as

necessary to align the

Cutting Head

MK-370EXP

MAINTENANCE & TROUBLESHOOTING

Rotate Clockwise or

Counterclockwise to

Adjust Height

1/4-inch Wrench

HORIZONTAL ROUGH ALIGNMENT

The Horizontal alignment will ensure that straight cuts (or Rip Cuts) are made.

(B)

Loosen front and rear

Guide Bar Retaining Bolts

(A)

Position Cutting Head

to normal Cut Depth

(C)

Move Guide Rail and Table

until the Blade is centered in

Cutting Groove