Chapter 8, Tag addresses, Chapter 8 tag addresses – MITSUBISHI ELECTRIC 2408f User Manual

Page 20: Home tab, Status tab

2408

f

& 2404

f

PROFIBUS Communications Handbook Tag Addresses

2408

f

and 2404

f

PROFIBUS Communications Handbook 8-1

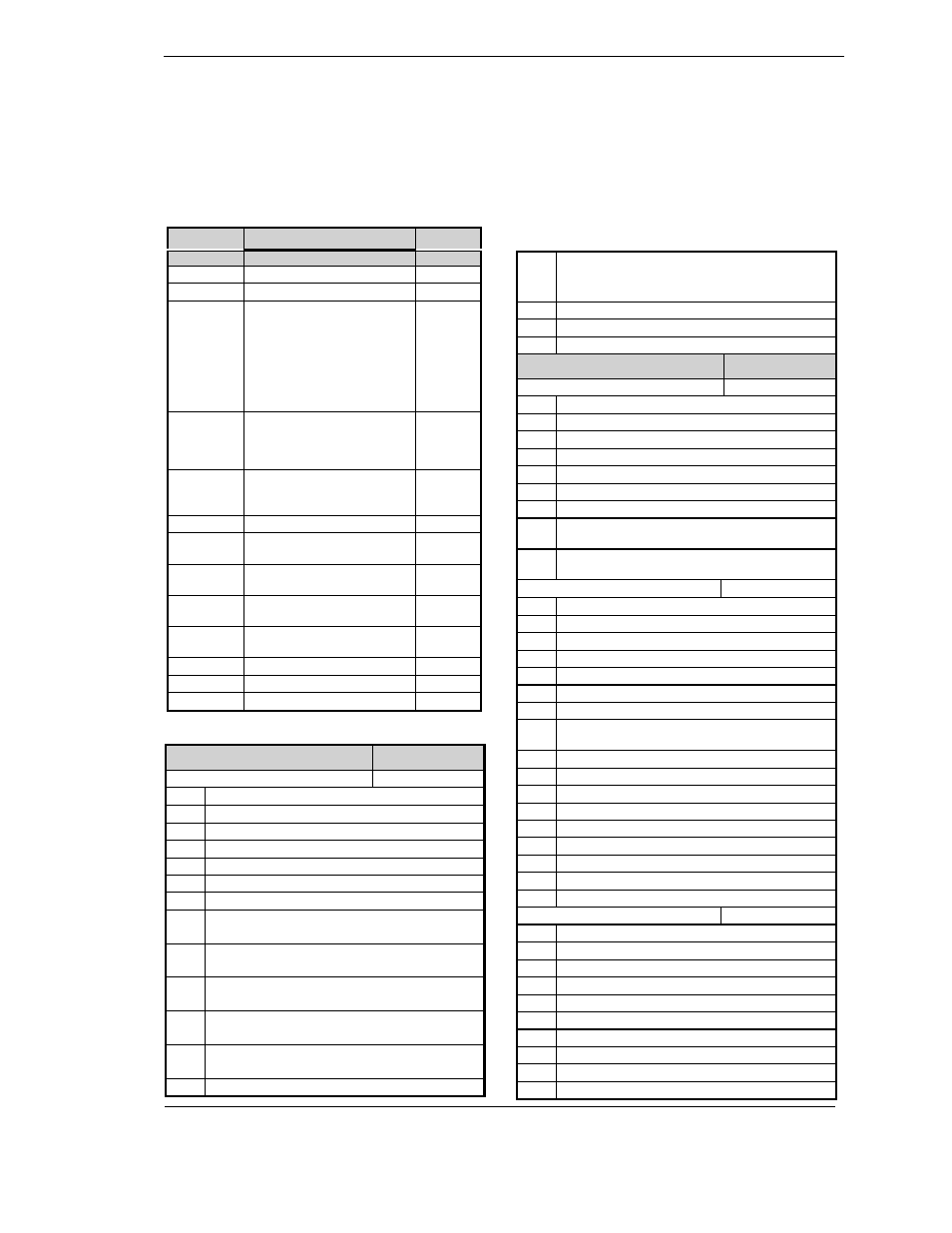

CHAPTER 8 TAG ADDRESSES

Tag addresses are used to identify parameters in the controller and are identical to the Modbus addresses which are also listed

in the Series 2000 Communications Manual, Eurotherm Part No. HA 026230. Tag addresses are used with the demand data

protcol to set up input/output data in the PLC or supervisory PC.. They are repeated here in the order in which they appear in

the GSD file.

They can also be read from the Windows Configurator by pointing to the parameter and clicking the right mouse button.

Controller

Home Tab

Tag

Display

Parameter Description

Address

Process Variable

1

0

0

Target setpoint

2

0

0

% Output power

For ON/OFF controllers the

following power levels must

be written:

Cool -100%

OFF 0%

Heat 100%

3

=D0

=D0

Working set point. Read only:

use Target set point or

currently selected set point (1

to 16) to change the value

5

,B

,B

Auto-man select

0: Auto

1: Manual

273

Pot Position

317

BB

Valve Posn (computed by

VP algorithm)

53

BB

VP Manual Output (alterable

in Man only)

60

,0

,0

Heater current (With PDSIO

mode 2)

80

DO

DO

Customer defined

identification number

629

Setpoint Span

552

Error (PV-SP)

39

Remote Input Value

26

Status Tab

Tag Address

Summary Output Status Word

75

BIT

DESCRIPTION

0

Alarm 1 State ( 0 = Safe 1 = Alarm )

1

Alarm 2 State ( 0 = Safe 1 = Alarm )

2

Alarm 3 State ( 0 = Safe 1 = Alarm )

3

Alarm 4 State ( 0 = Safe 1 = Alarm )

4

Manual Mode ( 0 = Auto 1 = Manual )

5

Sensor Break ( 0 = Good PV 1 = Sensor Broken )

6

Loop Break ( 0 = Good closed loop

1 = Open Loop )

7

Heater Fail ( 0 = No Fault

1 = Load fault detected )

8

Tune Active ( 0 = Auto Tune disabled

1 = Auto Tune active)

9

Ramp/Program Complete ( 0 = Running/Reset

1 = Complete )

10

PV out of range ( 0 = PV within table range

1 = PV out of table range )

11

DC control module fault (0= Good. 1= BAD)

12

Programmer Segment Synchronise

(0 = Waiting,

1 = Running)

13

Remote input sensor break ( 0 = Good, 1 = Bad)

14

IP1 Fault

15

Reserved

Status Tab

Tag Address

Fast Status Byte

74

BIT

DESCRIPTION

Bit 0

Alarm 1 State ( 0 = Safe 1 = Alarm )

Bit 1

Alarm 2 State ( 0 = Safe 1 = Alarm )

Bit 2

Alarm 3 State ( 0 = Safe 1 = Alarm )

Bit 3

Alarm 4 State ( 0 = Safe 1 = Alarm )

Bit 4

Manual Mode ( 0 = Auto 1 = Manual )

Bit 5

Sensor Break ( 0 = Good PV 1 = Sensor Broken )

Bit 6

Loop Break ( 0 = Good closed loop 1 = Open

Loop )

Bit 7

Heater Fail ( 0 = No Fault 1 = Load fault

detected )

Control Status Word

76

BIT

DESCRIPTION

0

Control algorithm Freeze

1

PV input sensor broken

2

PV out of sensor range

3

Self Tune failed

4

PID servo signal

5

PID debump signal

6

Fault detected in closed loop behaviour (loop

break)

7

Freezes the integral accumulator

8

Indicates that a tune has completed successfully

9

Direct/reverse acting control

10

Algorithm Initialisation flag

11

PID demand has been limited.

12

Autotune enabled

13

Adaptive tune enabled

14

Automatic Droop compensation enabled

15

Manual / Auto mode switch

Instrument Status Word

77

BIT

DESCRIPTION

0

Config/Oper mode switch

1

Disables limit checking

2

SRL ramp running (Read Only)

3

Remote setpoint active

4

Alarm acknowledge switch.

5

Reserved

6

Reserved

7

Reserved

8

Reserved