V-belt replacement, Gap insert removal & installation – Grizzly G0709 User Manual

Page 72

-70-

Model G0709 (Mfg. Since 5/11)

v-belt Replacement

Tools Needed

Qty

phillips screwdriver #2 ...................................... 1

Wrench 17mm.................................................... 1

To replace the v-belts on the lathe:

1. disConneCt lAthe FroM poWer!

2. remove the headstock gear cover.

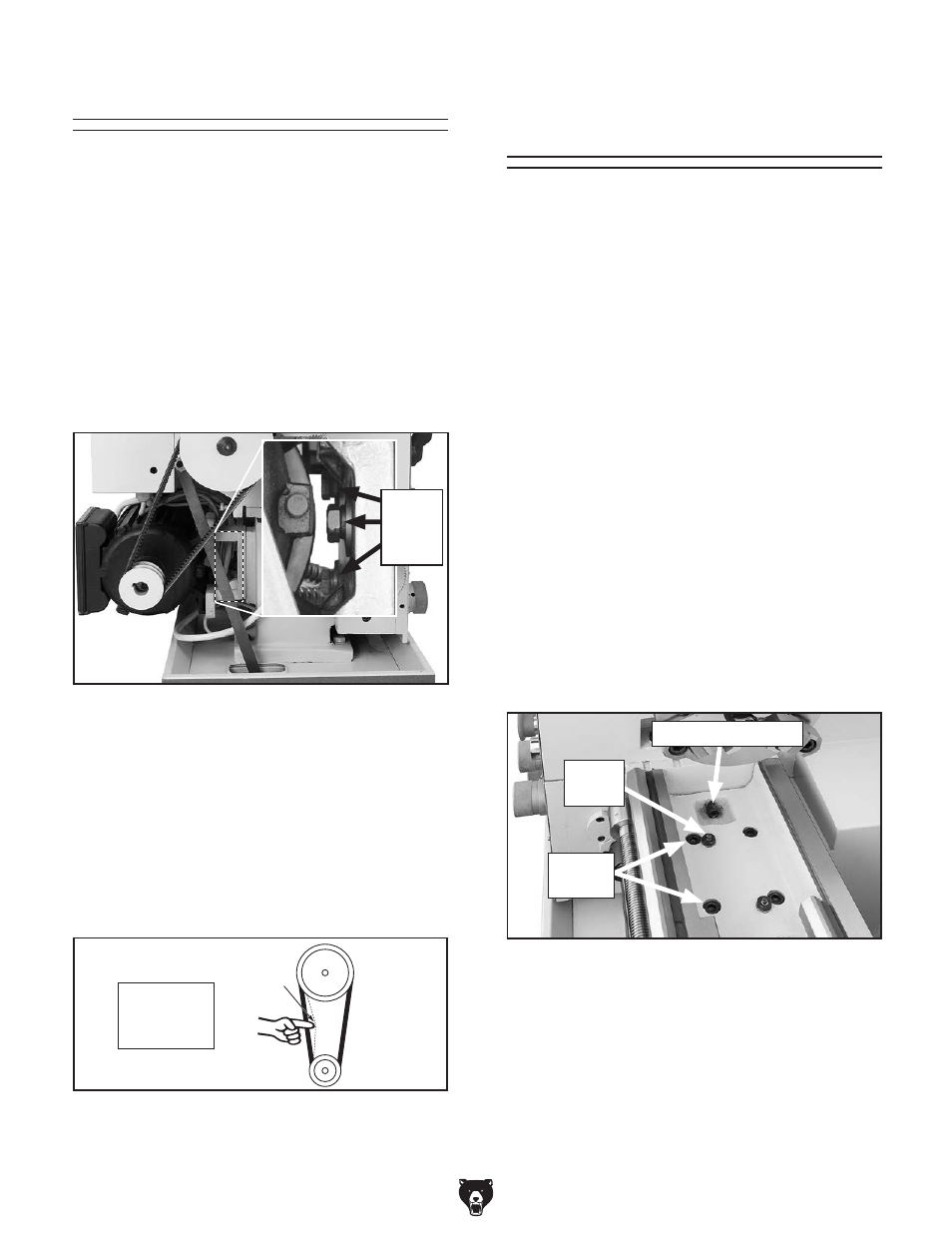

3. loosen the motor mount bolts shown in

figure 113, and slide the motor up, remove

the belts.

figure 113. location of motor mount bolts.

Motor

Mount

Bolts

Gap Insert Removal

& Installation

this lathe is equipped with a removable gap

insert that will allow for turning large diameter

workpieces. the gap was seated, pre-loaded,

and then ground for precise mating and alignment

at the factory. removing the gap can cause the

lathe insert to slightly spring out of shape. When

re-installed, there is no guarantee that original

alignment and flush mating will be the same. For

this reason, removing the gap is considered a

permanent alteration to the lathe, even if it is later

re-installed.

Tools Needed

Qty

open end Wrench 14mm .................................. 1

hex Wrench 8mm .............................................. 1

heavy dead Blow hammer ............................... 1

Miscellaneous C-Clamps ................ As required

Wooden Blocks ............................... As required

To remove the gap:

1. disConneCt lAthe FroM poWer!

2. remove the four cap screws that secure the

gap to the bed (see

figure 115).

figure 115. gap retaining fasteners.

Cap

screws

dowel

pin

preload set screw

3. tighten the dowel-pin jack nut (see figure

115) to draw the pins from the gap.

4. install the new belts as a matched set so they

equally share the load.

5. push down on the motor with one hand to

tension the belts.

6. tighten the motor mount bolts and check the

belt deflection, as shown in

figure 114, and

re-adjust if necessary.

figure 114. Belt deflection.

Spindle

Pulley

Deflection

Motor

Pulley

deflection

should be

Approx.

1

⁄

4

"

7. replace the headstock gear cover.