Feed direction lever, Feed selection lever – Grizzly G0709 User Manual

Page 48

-46-

Model G0709 (Mfg. Since 5/11)

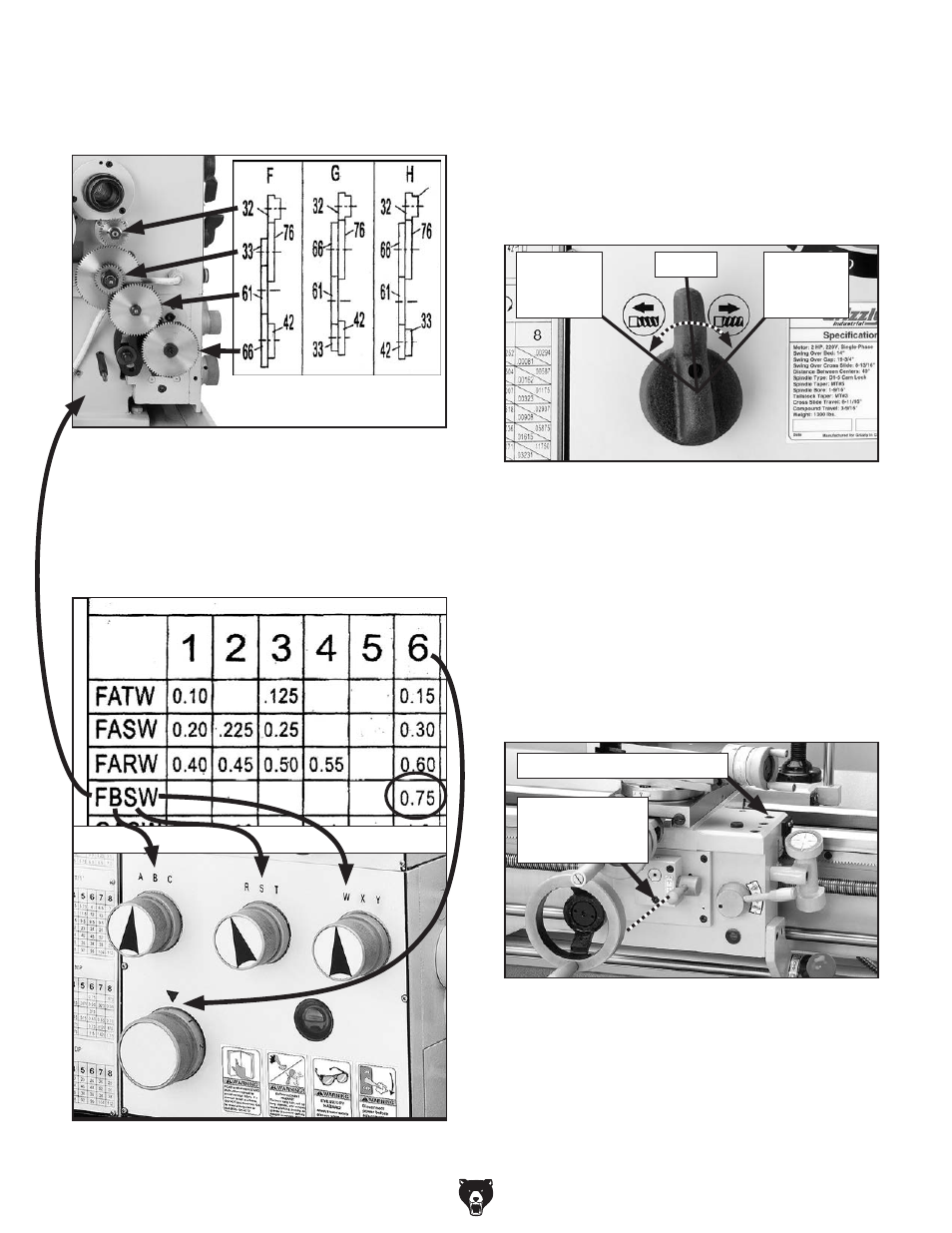

4. leaving 0.003"–0.005" backlash between

gear teeth, arrange the change gears to

match the order under "F" (see

figure 55).

5. rotate the spindle by hand to verify no bind-

ing exists, and re-install the gear cover.

6. Move the threading dials to the combination

of

fbSW6, as shown in figure 56.

figure 56. thread control settings for 0.75 pitch.

figure 55. Change gear and chart relationship.

feed Direction Lever

When threading, the feed direction lever (see

figure 57) moves the carriage to the left toward

the headstock (forward), and moves the carriage

to the right toward the tailstock (reverse). the

leadscrew will not turn when the feed direction

lever is in the neutral position.

feed Selection Lever

to prevent apron and drive system damage, the

apron is equipped with an internal lockout, mean-

ing that in order to engage the half nut for thread-

ing, this lever

(see figure 57) must be moved to

the central or the disengaged position. Also keep

in mind that just as with longitudinal feed opera-

tions, before any threading operation. you must

first verify the carriage lock (see

figure 57) is

disengaged, or the feed system may be damaged.

figure 58. Feed selection lever disengaged.

lever Centered

to disengage

Feed

Carriage lock disengaged

figure 57. Feed direction controls for threading.

Carriage

Feeds to

the right

Carriage

Feeds to

the left

neutral