Notice, Chuck & faceplate installation – Grizzly G0709 User Manual

Page 30

-28-

Model G0709 (Mfg. Since 5/11)

To install the chuck or face plate:

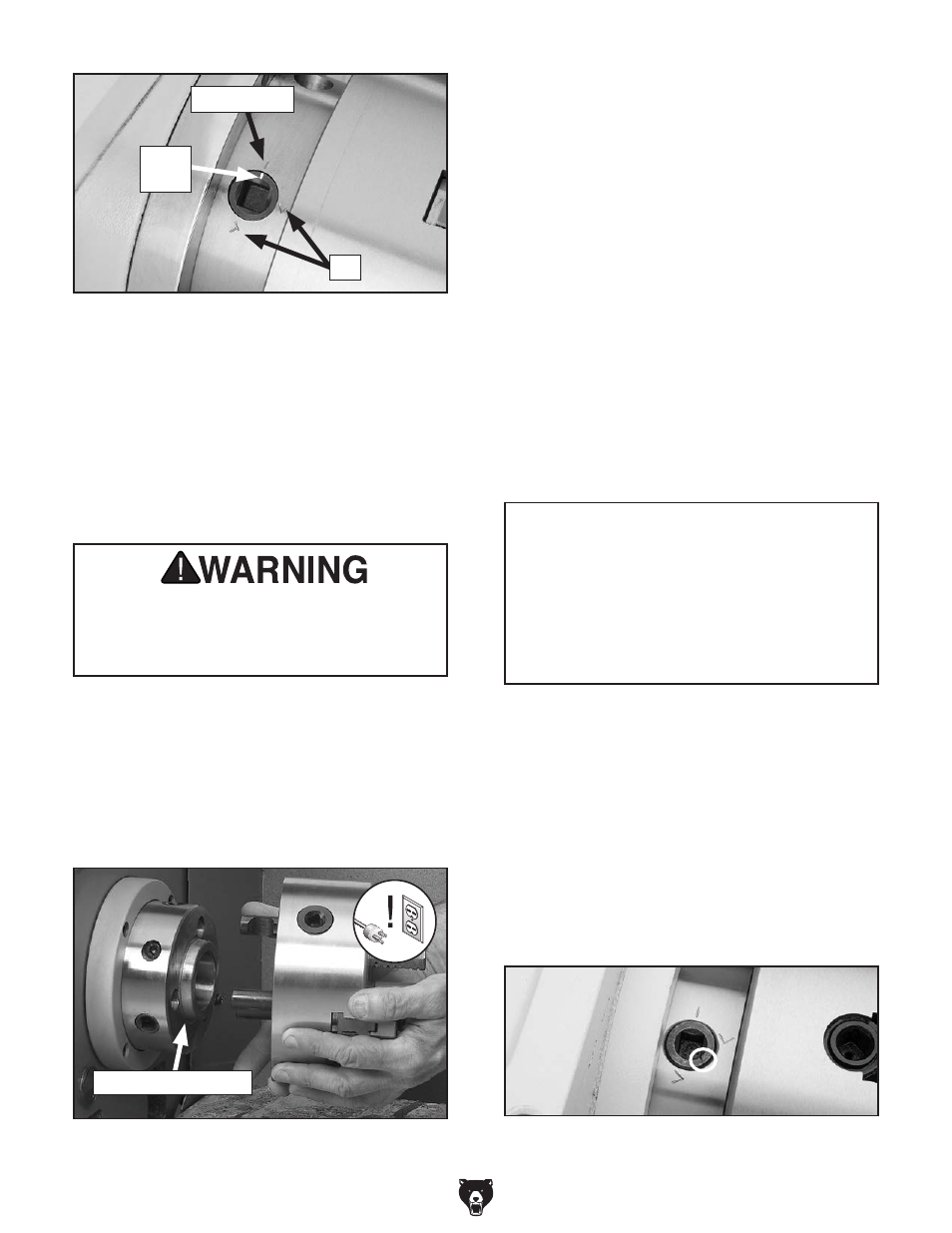

figure 21. indicator arrows.

spindle line

Cam

line

v's

4. using a dead blow hammer or other soft mal-

let, lightly tap around the outer circumference

of the chuck body to break the chuck free

from the cam-locks and from the spindle nose

taper.

cAUTION: The chuck may come off at this

point, so it is important you are ready to

support its weight.

Large chucks are very heavy. Always get

assistance when removing or installing

large chucks to prevent personal injury or

damage to the chuck or lathe.

5. use a rocking motion to carefully remove the

chuck from the spindle (see

figure 22).

—if the chuck does not immediately come off,

rotate the spindle approximately 60˚ and

tap again. Make sure all the marks on the

cams and spindle are in proper alignment.

chuck & faceplate Installation

1. disConneCt lAthe FroM poWer!

2. place a piece of plywood across the lathe

ways just under the chuck, and use a chuck

cradle if desired.

3. Make sure the chuck taper and spindle taper

mating surfaces are perfectly clean.

4. inspect and make sure that all camlock studs

are undamaged, are clean and lightly oiled,

and that the camlock stud cap screws are in

place and snug.

—if the camlock studs have not yet been

installed in the chuck or faceplate, com-

plete the

camlock Stud Installation on

the next page

.

NOTICE

Never install a chuck or faceplate without

having the camlock cap screws in place

or fully tightened. If you ignore this notice,

once installed the chuck may never be able

to be removed since the camlock studs will

turn with the camlocks and never release.

5. Align the chuck-to-spindle timing marks (see

figure 24), and slide the chuck onto the

spindle.

6. turn a camlock with the chuck wrench until

the cam mark falls between the "v" marks as

shown in

figure 23.

— if the cam lock mark stops outside of the

“v” marks, remove the chuck and adjust

the cam stud height of the offending studs

one full turn up or down (see

figure 23).

figure 23. Cam-lock in the locked position.

figure 22. installing and removing a typical

camlock style chuck.

spindle nose taper