Notice – Grizzly G0709 User Manual

Page 70

-68-

Model G0709 (Mfg. Since 5/11)

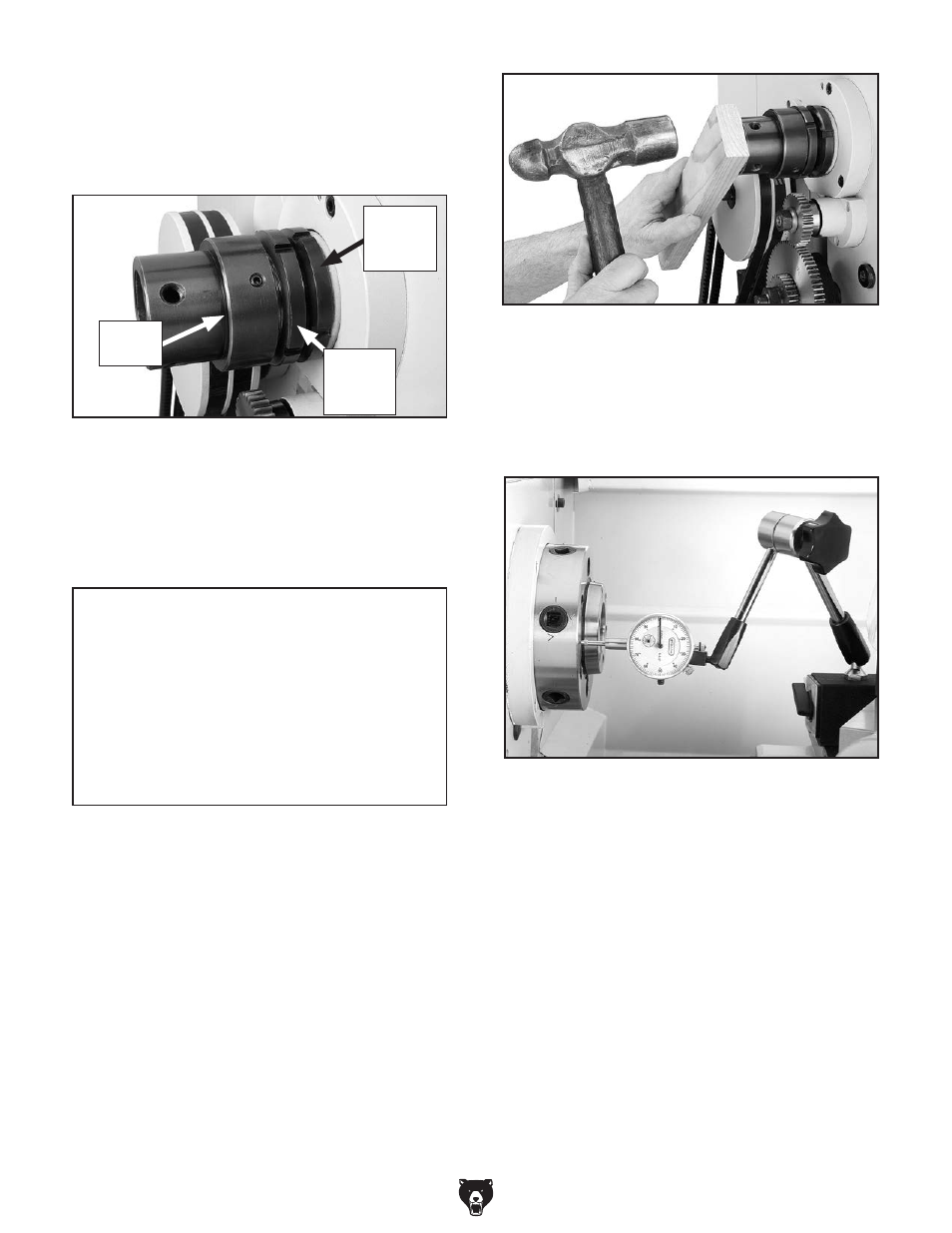

4. place the chuck wrench in the cam-lock

socket to keep the spindle from rotating, and

loosen the outer spanner nut (see

figure

109) two turns. removing the spider hub is

not necessary.

figure 109. spindle spanner nuts.

inner

spanner

nut

outer

spanner

nut

spider

hub

5. loosen the inner spanner nut one turn. if

the spanner nut is too difficult to break loose

easily, you may have to tap on the outboard

spindle tube as explained in

Step 6 to help

unseat the spindle bearings.

NOTICE

for the next step, DO NOT strike the wood-

en block with excessive force. If you do,

you can cause the tapered roller bearings

to indent the mating races. If this dam-

age occurs, one or more spindle bearings

will have to be replaced, as this damage

will generate vibration at higher spindle

speeds.

6. since the spindle bearings may unseat eas-

ily without great force, hold a wood block

against the outboard end of the spindle, and

tap the block a few times with a three or four

pound hammer (see

figure 110). your goal

is to slide the spindle forward just enough to

introduce spindle end-play that can be heard

or felt by hand.

figure 110. un-seating spindle bearings to intro-

duce spindle end-play.

7. place a dial indicator on the cross slide and

move the carriage toward the headstock until

the contact point of the indicator touches the

spindle face (see

figure 111).

figure 111. dial indicator setup.

8. Move the carriage an additional 0.100" toward

the headstock, and zero the dial indicator.