Operation – Grizzly G0649 User Manual

Page 32

-30-

g0649 Welding downdraft table

Operation

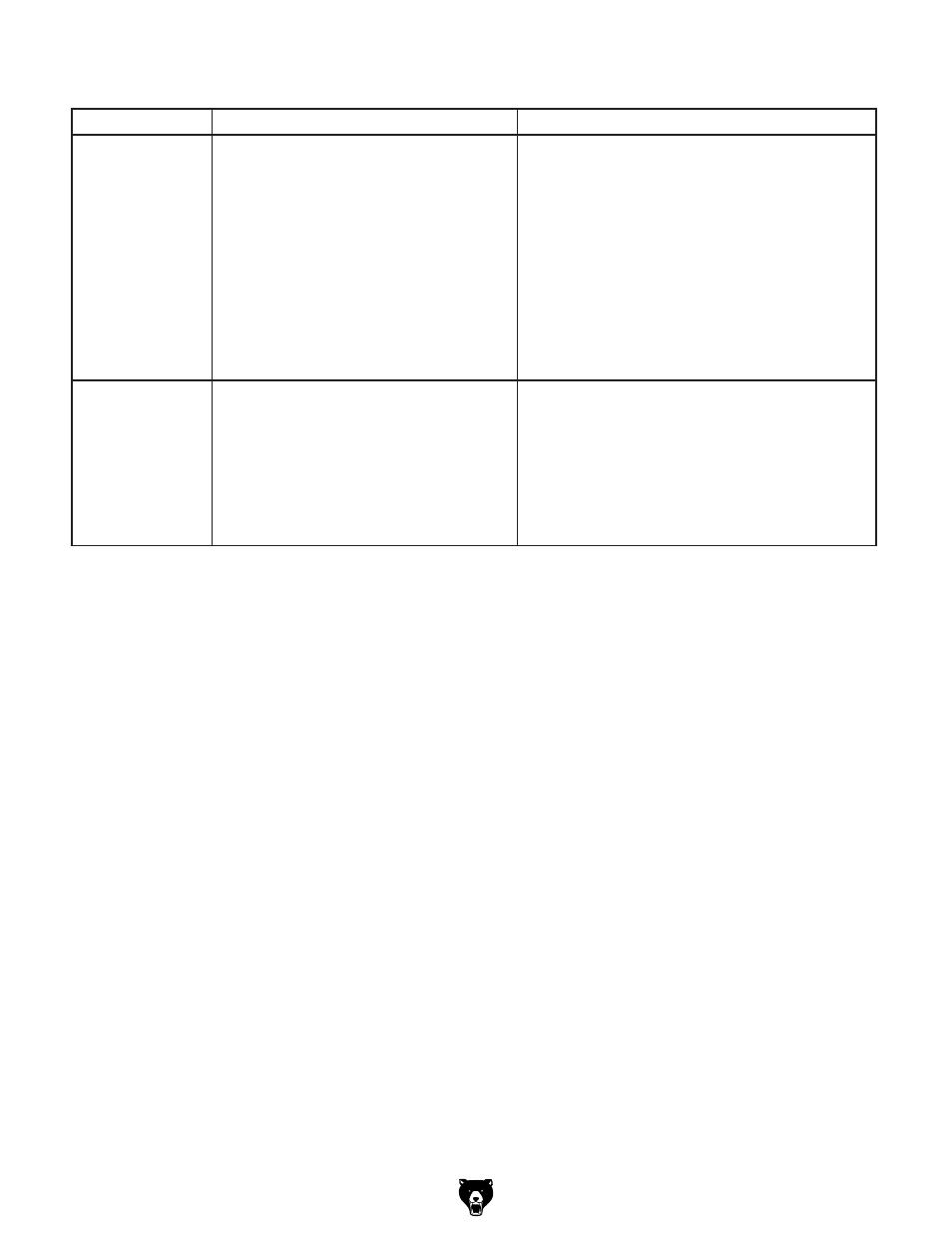

Symptom

Possible cause

Possible Solution

Suction CFM is

lower than normal.

1. door or cabinet is at fault.

2. Motor fan is turning too slow.

3. Slag screen is at fault.

4. rolling filter is at fault.

5. Vibrating filter is at fault.

6. hEpa filter is at fault.

7. Fan system is at fault.

1. Make sure that all doors are closed, seals do not

leak.

2. use the frequency drive control panel to increase

the motor supply voltage to 60hz.

3. remove slag drawer and clean slag screen.

4. increase rolling-filter advance intervals to expose

new filter paper more often to maintain CFM.

5. Manually clean the vibrating filter or replace.

6. Manually clean the hEpa filter or replace.

7. Fan motor has lost rpM, adjust/troubleshoot

frequency drive and replace motor or frequency

drive if required.

high rolling-filter

usage.

1. incorrect machine usage at fault.

2. rolling filter advance timing at fault.

3. Workpiece preparation at fault.

1. Eliminate idle time. do not let machine run between

welding jobs, shift changes, or breaks.

2. Clean all filters. delay rolling-filter advance tim-

ing and/or decrease amount of new filter that is

exposed during advance cycles.

3. reduce smoke and fumes. grind, scrape, strip or

sandblast away workpiece coatings to a minimum

of 4" away from location to be heated.