Control panels – Grizzly G0649 User Manual

Page 19

g0649 Welding downdraft table

-17-

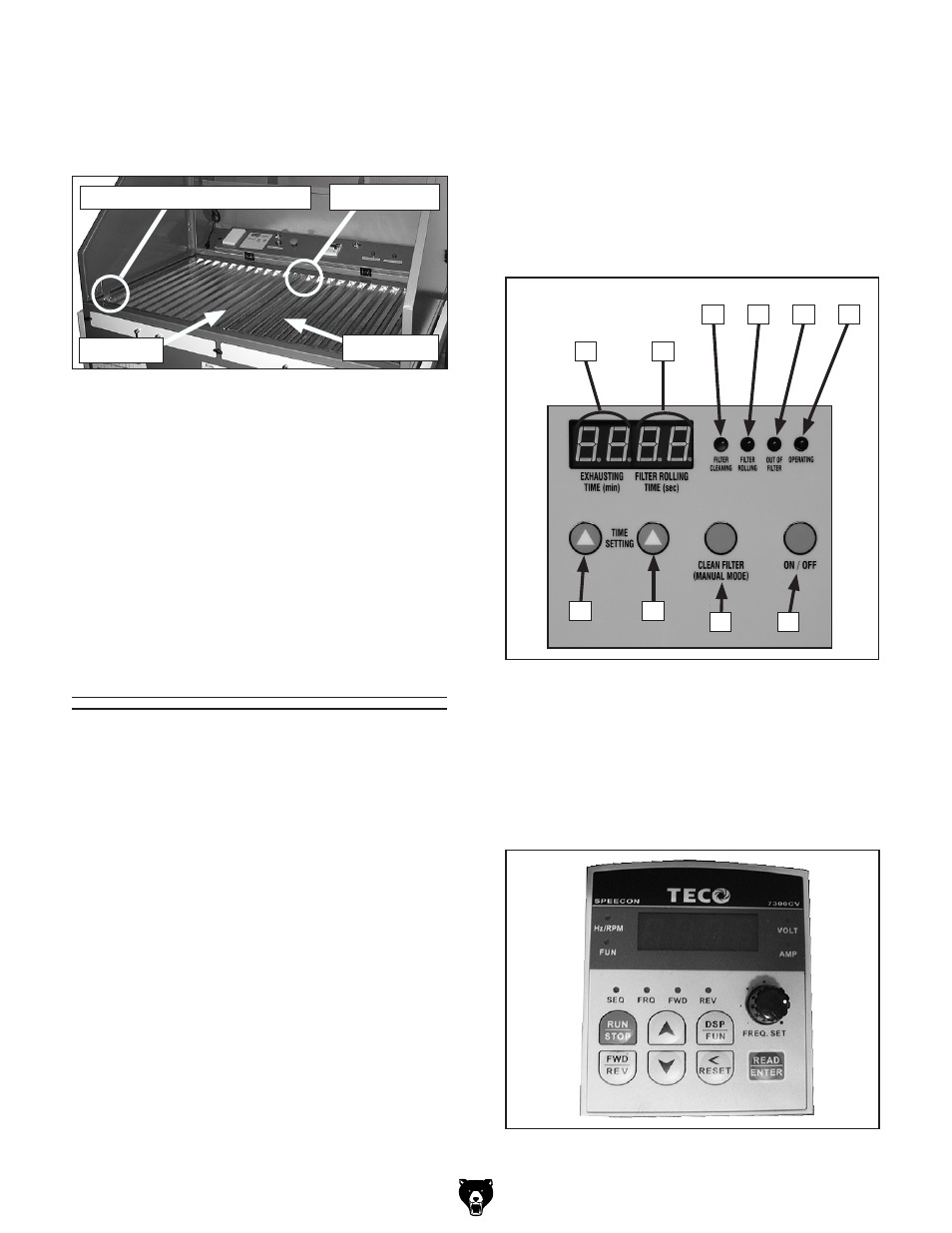

figure 8. Frequency drive control panel.

a

B

C

d

E

F

g

h

i

J

figure 7. digital control panel.

A. EXhAuSTinG TiME (min): displays in min-

utes, how much welding time is allotted

before new filter paper is exposed.

b. fiLTER ROLLinG TiME (sec): displays in

seconds, the duration of roller-filter advance.

c. fiLTER cLEAninG: lamp lights when the

vibrating-type filter is being de-caked.

D. fiLTER ROLLinG: lamp lights when the

roller-type filter is advancing.

E. OuT Of fiLTER: lamp lights when the

roller-type filter has run out and needs chang-

ing.

f. OPERATinG: lamp lights indicating that the

machine is running.

G. SETTinG TiME (Left button): allows for

changing the

EXhAuSTinG TiME.

control Panels

4. Connect welding ground cable to the ground

stud on the left-hand corner of the table and

make sure the ground strap is connecting

both left and right work tables (

figure 6).

h. SETTinG TiME (Right button): allows for

changing the

fiLTER ROLLinG TiME.

i. cLEAninG fiLTER (MAnuAL MODE)

button: When the machine is OFF, press

this button to de-cake vibrating filter.

J. On/Off button: toggles machine operation

ON and OFF.

K. fREQuEncy DRivE cOnTROL PAnEL:

allows you to adjust the fan motor supply

voltage frequency which in turn changes the

suction CFM. this is an important adjustment

if you want to maintain the flux gas atmo-

sphere around the point of welding.

figure 6. grounded welding work tables.

Welding Cable ground Stud

ground Strap

note: Under both work tables exists a plas-

tic frame that insulates the machine digital

circuitry from welding current fluctuations.

The ground strap shown above must con-

nect both left and right tables. If this ground

strap is missing, loose, or is disconnected,

and the welding cable ground is connected

to the welding ground stud, the right table

will be poorly grounded and be an insufficient

ground required for quality welding results.

left table

right table