Schedule, Lubrication, Cleaning – Grizzly G0649 User Manual

Page 24

-22-

g0649 Welding downdraft table

SEcTiOn 6: MAinTEnAncE

Always disconnect power

to the machine before

performing maintenance.

failure to do this may

result in serious person-

al injury.

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

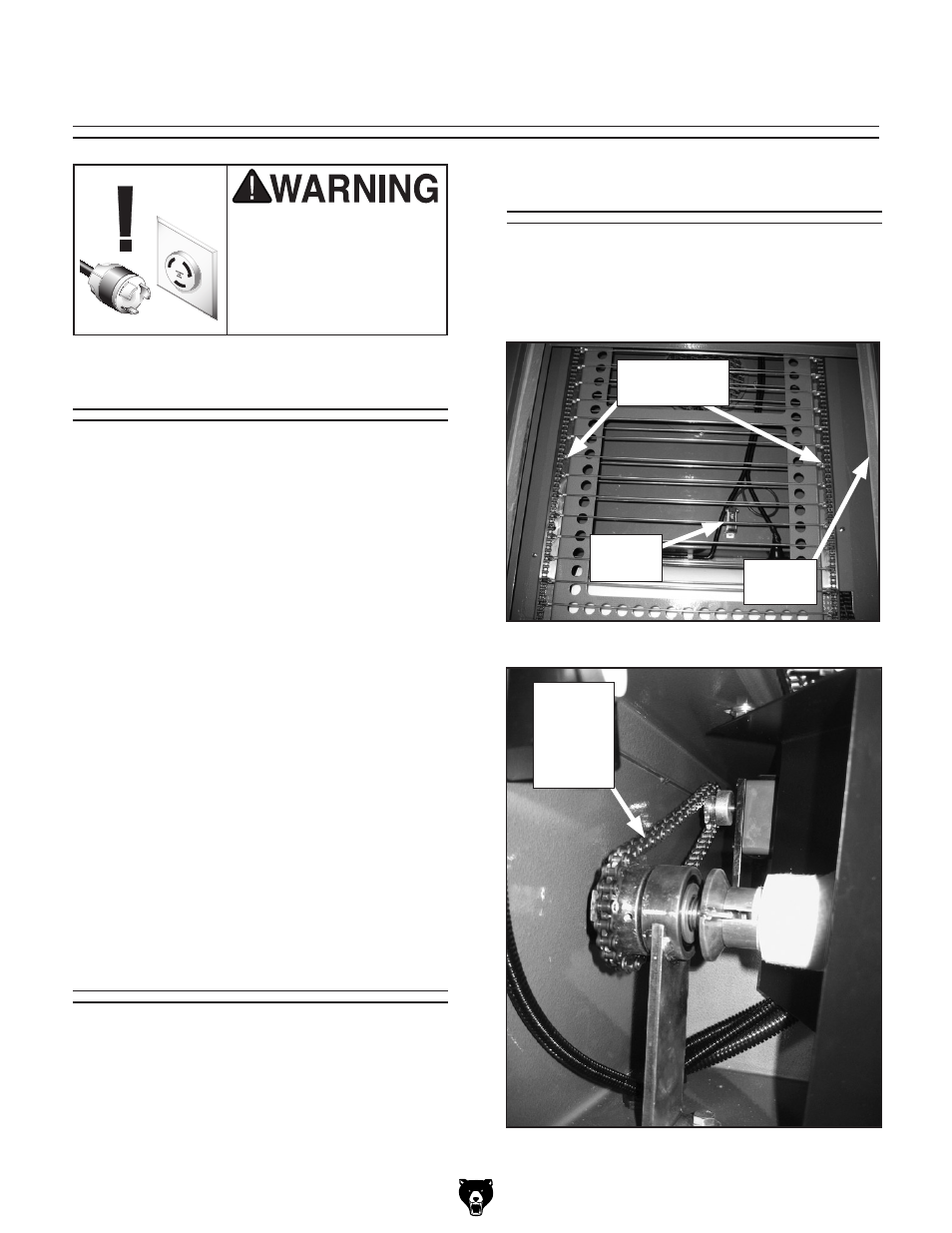

Daily check/Maintenance:

•

leaking seals or ducting.

•

Worn or damaged power cord.

•

Worn or missing plastic work table insulators

on the table support ledges (

figure 18).

•

Clean slag screens, and empty dust drawer.

•

Correct for any other unsafe condition.

Weekly check/Maintenance:.

•

Carefully wipe off any dust caked on the elec-

tronic eye lens (see

figure 18 for location).

Monthly check/Maintenance:

•

disconnect from power and vacuum and

wipe out any dust buildup from the inside of

the control box and filter cabinets. do not use

compressed air close to the filters or electri-

cal components.

•

once a month, lubricate the drive chains.

Schedule

figure 19. recovery axle drive chain.

use a dry rag to wipe all drive chains and sprock-

ets clean; then brush the chain links with a thin

coat of light machine oil. refer to

figures 18–20

for locations.

Lubrication

Cleaning the Model g0649 is relatively easy. put

on an oSha approved respirator and vacuum

excess dust, and wipe off the remaining dust with

a damp cloth. do not use harsh detergents or sol-

vent on the cabinet, and never spray compressed

air close to filters or electrical components.

cleaning

Electric

Eye

figure 18. Conveyor system.

oil

recovery

axle

drive

Chain

oil Conveyor

Chains

plastic

insulator