Long-term storage slag-screen cleaning – Grizzly G0649 User Manual

Page 25

g0649 Welding downdraft table

-23-

figure 20. Conveyor drive chain.

oil

Conveyor

drive Chain

if this machine needs to be stored for a long

period of time, make sure that the following condi-

tions are met:

•

remove and manually clean the vibrating

filters and the hEpa filter.

•

Clean and lubricate the drive chains.

•

place the machine in a dry area where the

humidity range will not vary beyond 30% to

95% and the storage temperature will not

vary beyond -13° to 158°F.

•

place a moisture-absorbing desiccant bag in

the control panel box with a note to remove

when the machine is put back in operation.

•

Cover the machine to protect it from dust

and moisture.

Long-Term Storage

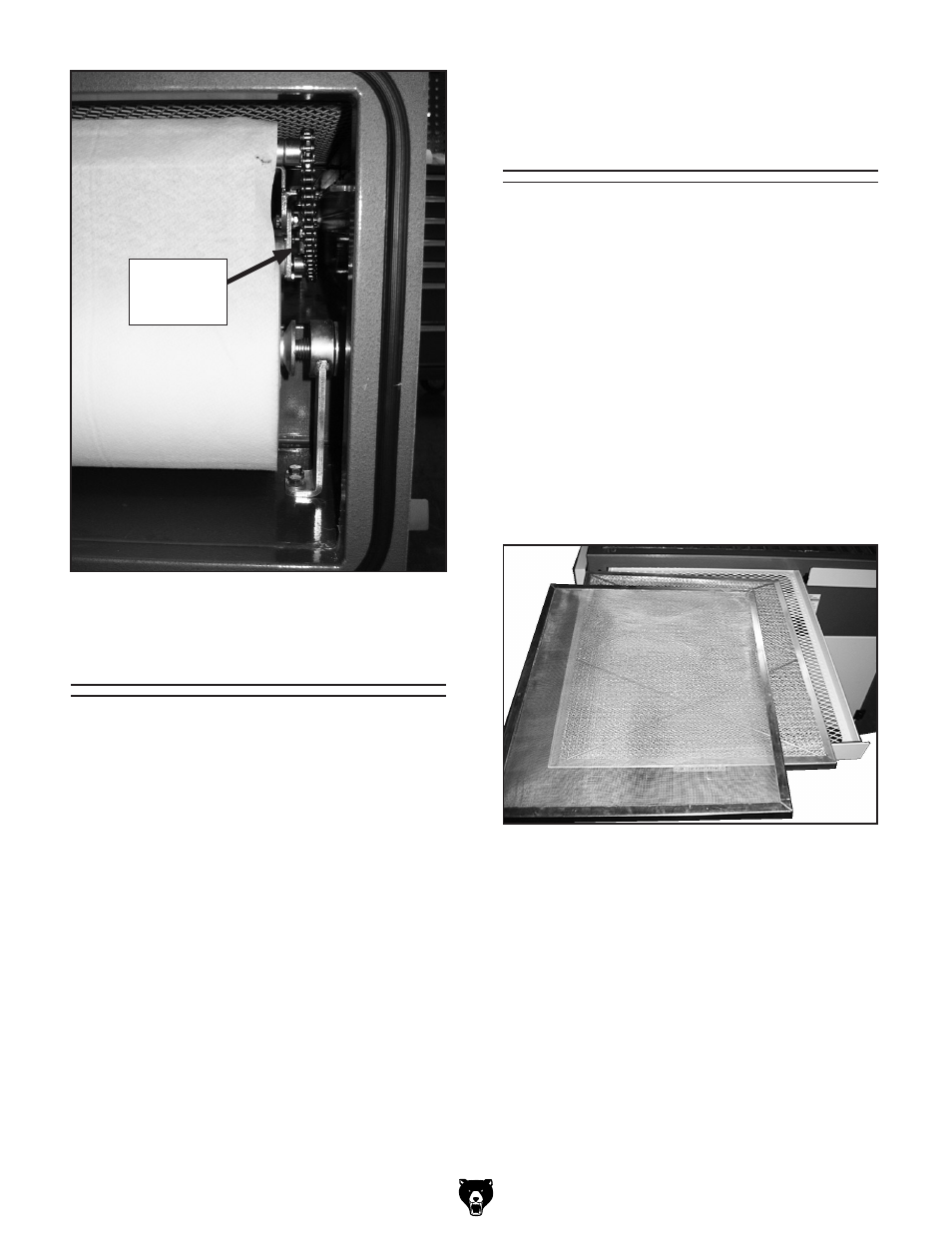

Slag-Screen

cleaning

Make sure that you clean the slag screen often

and inspect for holes or damage. under correct

use, this screen should last for years.

Tools needed

Qty

Soft Brass Wire Brush ....................................... 1

oSha approved respirator .............................. 1

Shop Vacuum .................................................... 1

To perform this procedure:

1. unplug thE MaChinE!

2. put on your respirator, unlock and remove

the slag drawer, and then the screen (

figure

21).

3. inspect the drawer face seal for evidence of

leaks or tears. reseal as required.

4. Carefully use a wire brush and tap the screen

to remove the built up dust and slag. if a piece

of solder or slag has welded to the screen, do

not pry it off or you may tear a hole in the

screen.

5. Vacuum up the loose dust and reinstall the

screen and the slag drawer.

figure 21. Slag-screen.