Miter slot to blade parallelism – Grizzly G0651 User Manual

Page 73

model g0651/g0652 (mfg. since 1/10)

-71-

Miter Slot to Blade

parallelism

Tools Needed

Qty

adjustable square ............................................. 1

metal shim stock .............................. as needed

marker ............................................................... 1

your table saw will give the best results if the

miter slot is parallel with the blade. if these com-

ponents are not exactly parallel with each other,

your cuts and your finished work will be lower in

quality, but more importantly, the risk of kickback

will be increased.

To adjust the blade parallel to the miter slot:

1. disConneCt saW From poWer!

2. tilt the blade to 90°.

3. measure from the miter slot to a carbide tip

on the blade, as shown in

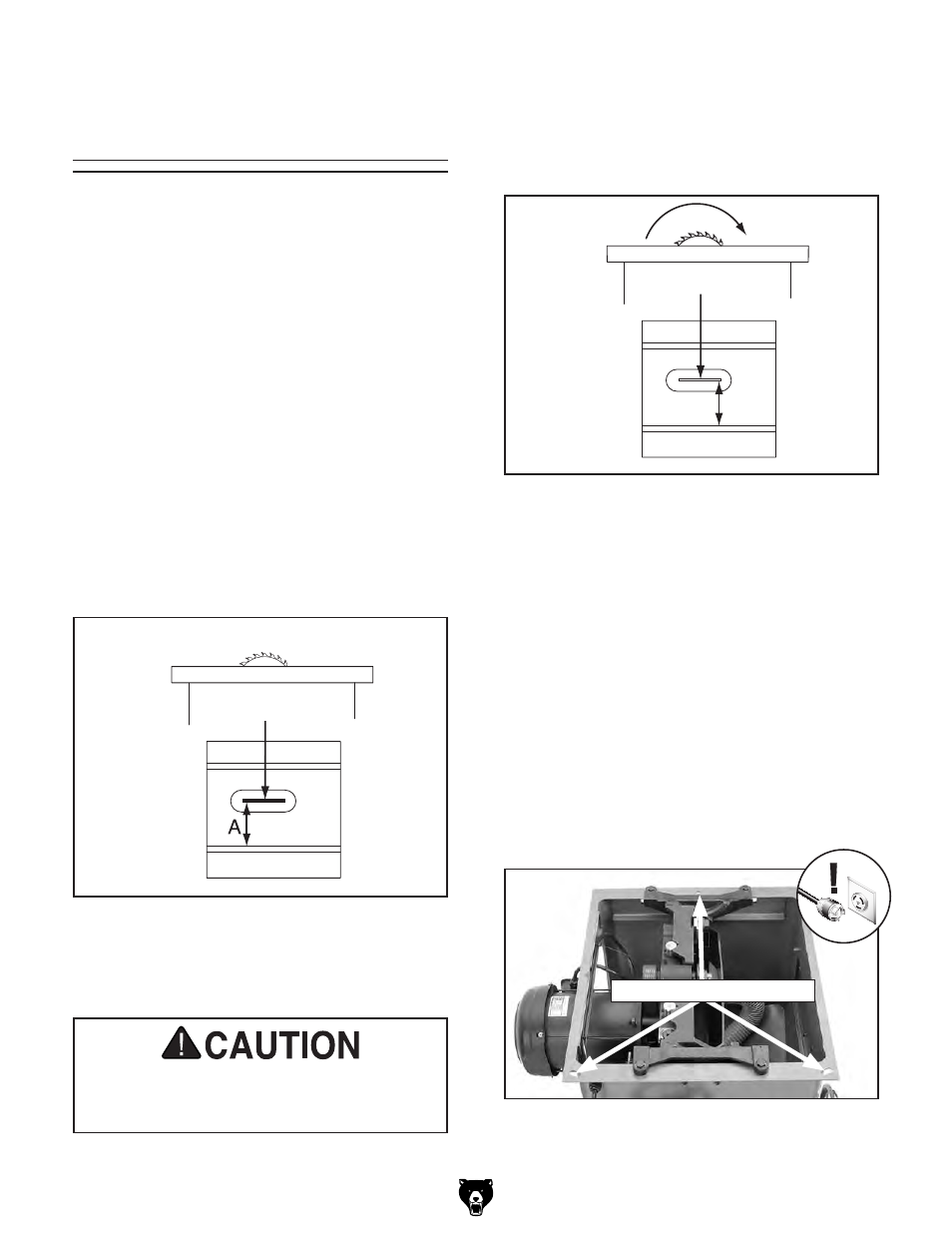

Figure 119.

4. mark the carbide tip with a marker where you

made this measurement.

The saw blade is dangerously sharp. use

extra care or wear gloves when handling

the blade or working near it.

Figure 119. measuring distance from miter slot

to carbide tip of blade.

7aVYZi^aiZYid.%§

;gdci

HI:E6

5. rotate the marked blade tip to the other end

of the table insert.

6. Compare the distance from the marked blade

tip to the miter slot, as shown in

Figure 120.

Figure 121. table mounting bolt holes (table top

removed for clarity).

—

if the distance between the blade tip and

the miter slot is not the same on both sides

of the table insert, the table will need to be

adjusted. proceed to

Step 7.

—if the blade tip measurement is the same

on both sides, go to

Step 8.

7. to adjust the table, loosen the three bolts

in the table mounting locations (see

Figure

121) and lightly tap the table in the direc-

tion needed to square the table to the blade.

repeat

Steps 2-6 until the blade and miter

slot are parallel. do not forget to tighten the

table mounting bolts when finished.

7aVYZi^aiZYid.%§

;gdci

7

HI:E7

Figure 120. measuring distance from miter slot

to carbide tip on opposite side of table insert.

table mounting locations