Frymaster H50 Series User Manual

Page 42

1-36

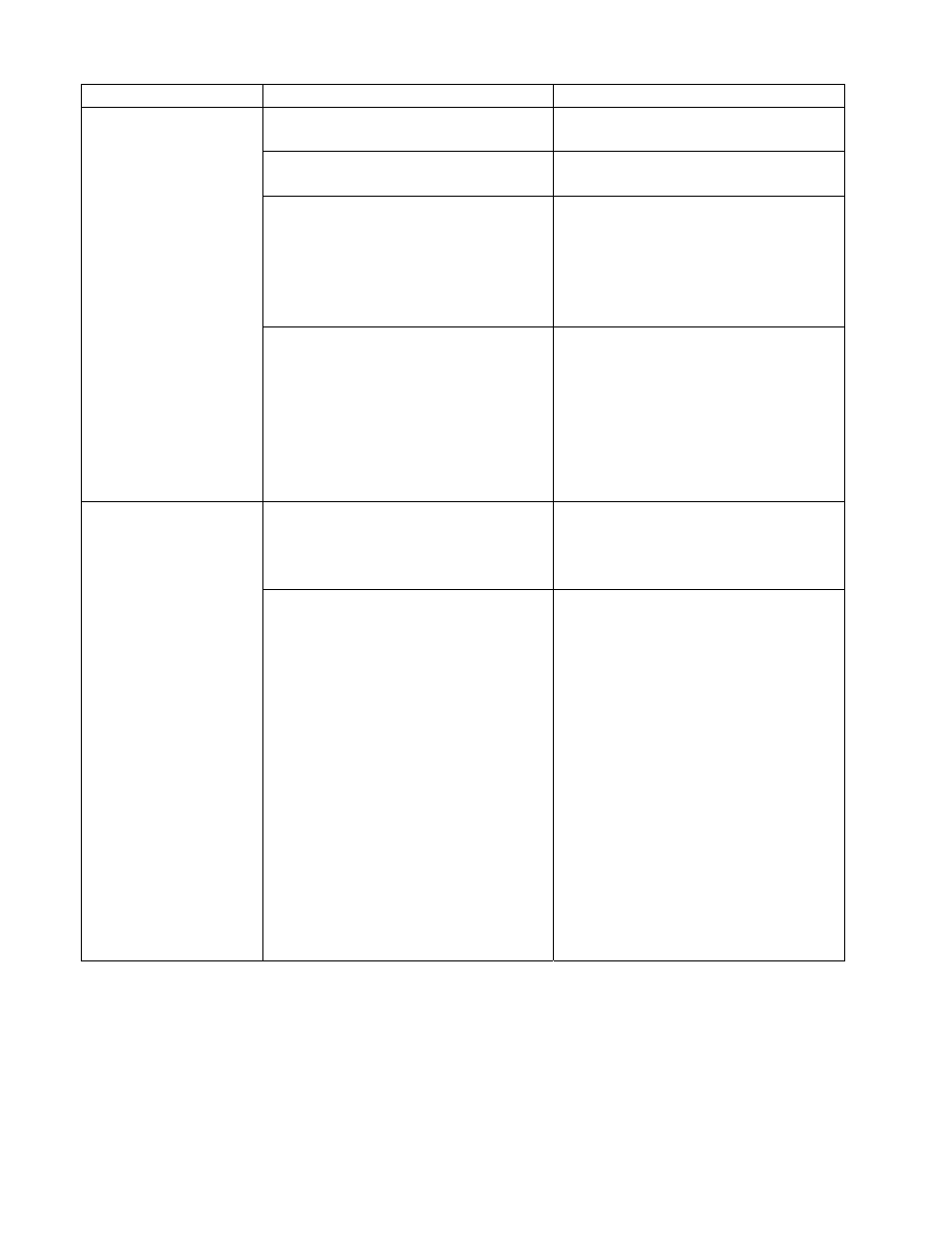

PROBLEM

PROBABLE CAUSES

CORRECTIVE ACTION

A. Gas valve in non-CE is in OFF

position.

A. Place gas valve in ON position.

B. Gas valve in non-CE is in OFF

position.

B. Place gas valve in ON position.

C. Improper incoming gas pressure.

Check: Incoming gas pressure is

in accordance with the

appropriate table on Page 1-23 of

this manual.

C. Bring incoming gas pressure into

accordance with the appropriate

table on Page 1-23 of this manual.

Gas supply or gas

valve is suspect.

D. Improper burner manifold gas

pressure.

Check: Burner manifold pressure

is in accordance with the appro-

priate table on Page 1-7 of this

manual.

D. Adjust the gas valve (see proce-

dure 1.4 of this manual) to bring

the burner manifold pressure into

accordance with the appropriate

table on Page 1-7 of this manual.

If the manifold pressure cannot be

properly adjusted, replace the gas

valve.

A. Damaged probe.

Check: While it is still in the fry-

pot, inspect the probe for damage.

A. Replace the probe if the body is

bent, dented, or cracked, or if its

wiring is burned, broken, frayed,

or kinked.

Temperature probe

is suspect.

B. Failed probe.

Check 1: Determine the tem-

perature of the oil in the frypot us-

ing a thermometer or pyrometer

placed at the tip of the probe, then

check the for a resistance through

J3 pins 2 and 6 (J1 pins 2 and 6

for the left side of a dual vat) ap-

proximately equal to that given in

the Probe Resistance Chart for the

corresponding temperature.

Check 2: Check for at least 5

megaohms of resistance through

each of the previously tested pins

to ground.

B. If probe does not test OK for both

checks, replace the probe.