I/o wiring, Grounding – IDEC SX5L Series User Manual

Page 33

3: I

NSTALLATION

AND

W

IRING

3-2

SX5L C

OMMUNICATION

T

ERMINAL

U

SER

’

S

M

ANUAL

I/O Wiring

Applicable Wires

For power and input wiring, use AWG18 or AWG16 (0.75 to 1.25 mm

2

) solid or stranded wires. When connecting two

wires together, use wires of the same size.

Terminal Tightening Torque

Tighten the I/O terminals to a toque of 0.6 to 1.0 N·m. Also tighten unused I/O terminals.

Wire Termination

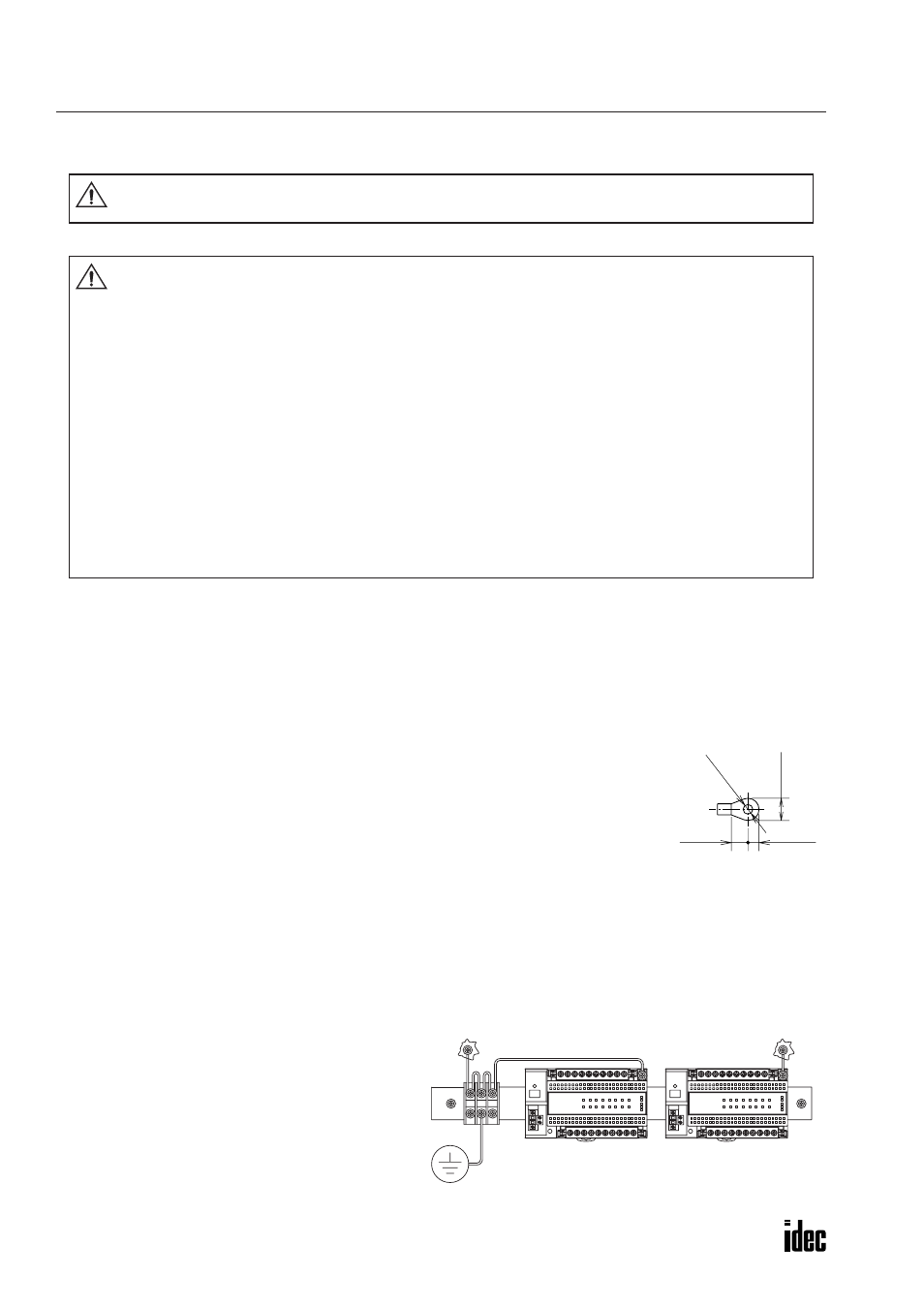

When using crimping terminals for wire termination, be sure to use an insulation tube on

the crimping terminal. One or two crimping terminals can be connected to one screw termi-

nal. Dimensions of an applicable crimping terminal are shown at right.

When wiring without using crimping terminals, strip the wire as long as the terminal clamp

plate (approx. 6 mm), and insert the wire until the wire insulation touches the end of the ter-

minal clamp plate.

Optional Jumper

When using the analog input module or Pt100

Ω input module, be sure to interconnect input terminals of each unused

channel using a wire or optional ring or spade type jumper. Otherwise an error may exceeds the rated value.

Grounding

The upper-right mounting hole has a FG terminal. Connect the FG terminal and control box as shown in the figure below.

Use a UL1007 AWG16 wire to connect the FG terminal to the ground (grounding resistance 100

Ω at the maximum).

The FG terminal is supplied with an M4 screw and

an embedded nut for ground connection when

mounting on a DIN rail. When mounting the SX5L

directly on a panel, prepare a proper screw for

grounding.

Remove paint from the panel surface for grounding

to make sure of electrical connection.

Warning

• Turn off the power to the SX5L before wiring the I/O and network cable. Failure to turn power off

may cause electrical shocks or fire hazard.

Caution

• Prevent metal fragments and pieces of wire from dropping inside the SX5L housing. Put a cover

on the SX5L module during wiring the I/O and network cable. Ingress of such fragments and

chips may cause fire hazard, damage, or malfunction.

• Run the power supply wiring as far away possible from motor lines to prevent malfunction.

• Use wires of an appropriate size to meet the voltage and current requirements. Using inappropri-

ate wires may cause overheat, resulting in possible fire hazard.

• Make sure of correct connection. Incorrect connection may cause overheat, resulting in possible

fire hazard.

• Do not run the I/O wiring in parallel with or in the vicinity of motor lines. Keep the I/O wiring

away from noise sources. Check for loose connection periodically. Loose connection may cause

overheat, resulting in possible fire hazard.

• Keep the power voltage and frequency within the rated values, otherwise the SX5L may be dam-

aged.

• Keep the input signal within the rated values, otherwise the SX5L may be damaged.

ø3.2 min.

5.2 min.

6.0 max.

3.0 max.

SERVICE

REQUEST

LON

SERVICE

REQUEST

LON