Vent clearances and framing, A. pipe clearances to combustibles, B. wall penetration framing – Hearth and Home Technologies Direct Vent Gas Appliance CNXT4236IT User Manual

Page 34

Heatilator • Caliber CNXT Series • 4047-132 Rev U • 11/08

34

B*

Framing should be

constructed of 2 X 4

lumber or heavier.

The center of the

framing hole is

1 in. (25mm) above

the center of the

horizontal vent pipe.

A*

Vent framing hole.

DO NOT PACK WITH

INSULATION OR OTHER

MATERIAL.

* Measured to center

of pipe.

10 in.

12 in.

* When using SLP pipe, minimum clearances from the vent pipe to combustible materi-

als at inside wall firestops are:

Top: 2-1/2 in. (64 mm)

Bottom: 1/2 in. (13 mm)

Sides: 1 in. (25 mm)

Note: Heat shields MUST overlap by a minimum of 1-1/2 in. (38 mm).

• DVP heat shield - designed to be used on a wall 4 in. to 7-1/4 in. (102 mm to 184

mm) thick.

• If wall thickness is less than 4 in. the existing heat shields must be field trimmed.

If wall thickness is greater than 7-1/4 in. an extended heat shield will be required.

• SLP heat shield - designed to be used on a wall 4-3/8 in. to 7-5/8 in. (111 mm to 194

mm thick).

• If wall thickness is less than 4-3/8 the existing heat shields must be field trimmed.

If wall thickness is greater than 7-5/8 in. an extended heat shield will be required.

3 in. (76 mm)

top clearance *

1 in. (25 mm)

clearance

bottom & sides

Heat

Shield

Wall

Shield

Firestop

Heat

Shield

WALL

3 in. (76 mm)

top clearance *

1 in. (25 mm)

clearance

bottom & sides

Heat

Shield

Wall

Shield

Firestop

Heat

Shield

WALL

3 in. (76 mm)

top clearance

1 in. (25 mm)

clearance around

vertical sections

(DVP Pipe Shown)

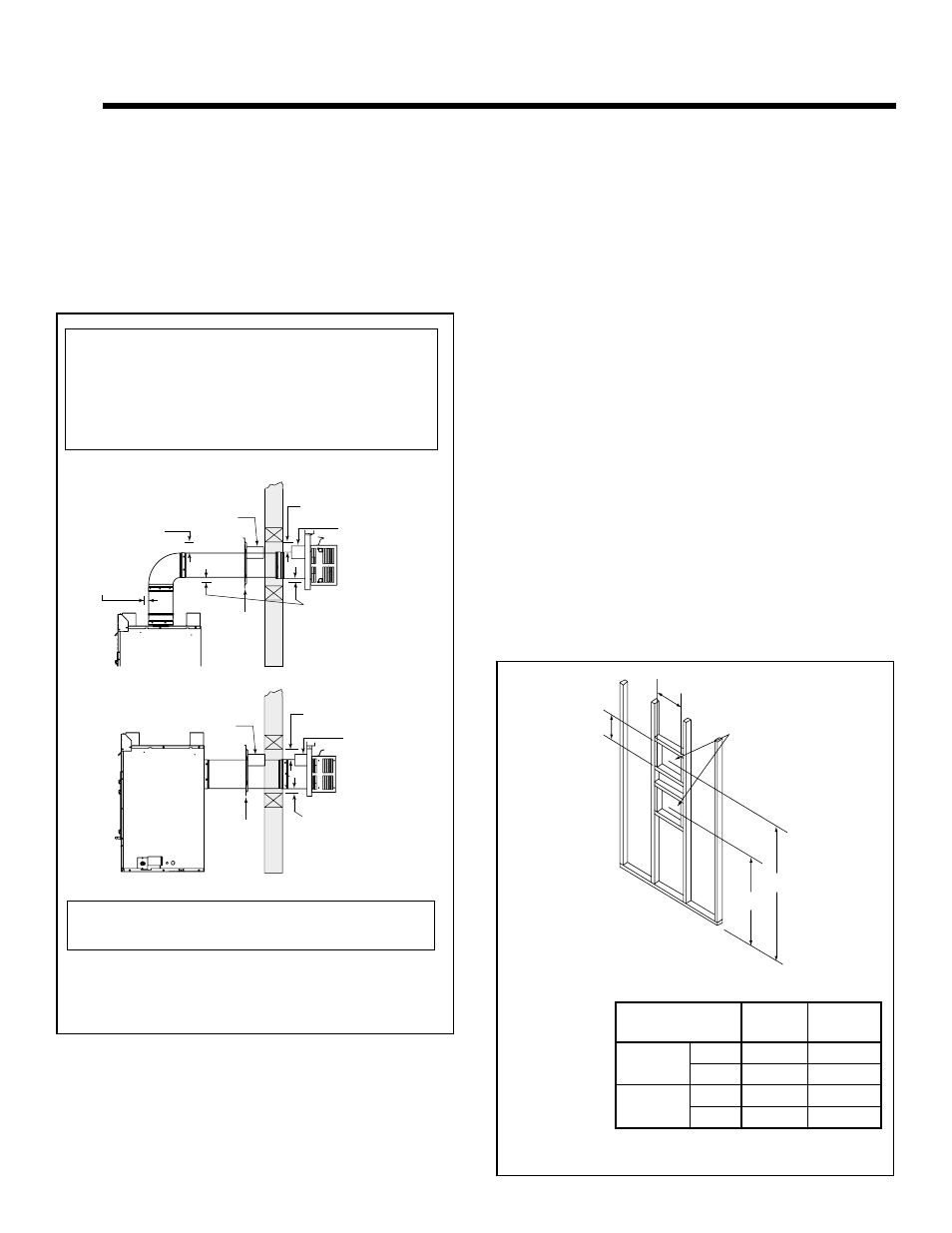

A. Pipe Clearances to Combustibles

WARNING! Risk of Fire! Maintain air space clearance to

vent. DO NOT pack insulation or other combustibles:

• Between

ceiling

fi restops

• Between wall shield fi restops

• Around vent system

Failure to keep insulation or other material away from

vent pipe may cause over heating and fi re.

8

8

Vent Clearances and Framing

B. Wall Penetration Framing

Combustible Wall Penetration

Whenever a combustible wall is penetrated, you must

frame a hole for the wall shield fi restop(s). The wall shield

fi restop maintains minimum clearances and prevents cold

air infi ltration.

• The opening must be framed on all four sides using the

same size framing materials as those used in the wall

construction.

• SLP pipe - A wall shield fi restop must be placed on each

side of an interior wall. A minimum 1 1/2 in. (38 mm)

overlap of attached heat shields must be maintained.

• DVP pipe - A wall shield fi restop is required on one side

only on interior walls. If your local inspector requires a

wall shield fi restop on both sides, then both wall shield

fi restops must have a heat shield attached to them.

• See Section 10.N. for information for regarding the

installation of a horizontal termination cap.

Non-Combustible Wall Penetration

If the hole being penetrated is surrounded by noncombus-

tible materials such as concrete, a hole with diameter one

in. greater than the pipe is acceptable.

Whenever a non-combustible wall is penetrated, the wall

shield fi restop is only required on one side and no heat

shield is necessary.

Figure 8.2 Wall Penetration

Figure 8.1 Horizontal Venting Clearances To Combustible Materi-

als

Model

A

Top Vent

B

Rear Vent

CNXT4236

inches

42 1/4

27 1/4

mm

1073

692

CNXT4842

inches

48 1/4

27 1/4

mm

1226

692