General, Before installation, Installation – Honeywell XL 800 SERIES User Manual

Page 3: Warning

Excel 800

3

EN1B-0410GE51

R0908A

WARNING

This equipment generates, uses, and can radiate radio

frequency energy, and if not installed and used in accordance

with the instructions manual, may cause interference to radio

communications. It has been tested and found to comply with

the limits for a Class A computing device pursuant to Subpart

J of Part 15 of FCC Rules, which are designed to provide

reasonable protection against such interference when

operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause interference,

in which case the user, at his own expense, will be required to

take whatever measures may be required to correct the

interference. Any unauthorized modification of this equipment

may result in the revocation of the owner’s authority to

continue its operation.

General

The XL800 Series is designed to provide heating, ventilating

and air-conditioning control. They can operate either

standalone, or networked to Honeywell central workstations

such as EBI. These controllers can also be used for smoke

control system monitoring and control, for monitor and control

of fire (UL864), and general purpose signaling (UL2017). In

UL 2017 applications, the product can be used as a type NM

(Non-Monitored) system. It is also approved for UL916

(Energy Management Equipment.)

The XL800 Series can be used for smoke control applications

when used in conjunction with a UL listed fire alarm control

panel (FACP) and UL listed fire fighters’ smoke control station

(FSCS).

Before Installation

1. Unpack door and remove the XL800 from carton. Check

equipment and report any damage to a Honeywell

representative.

2. Verify cabinet is installed correctly.

3. Securely mount the XL800 to a rigid structural surface

using at least four sets of 1/4 in. (6 mm) mounting

hardware (supplied locally).

NOTE:

Anchoring materials must be suitable for the

mounting surface (wood, concrete, steel).

Mounting must comply with all local codes.

4. Obtain correct number and type of sheet metal screws for

subpanel. Installation of a full-size subpanel requires six

no. 10 x ½-inch (13 mm) sheet metal screws (not

supplied). Installation of a smaller subpanel requires four

no. 10 x ½-inch (13 mm) sheet metal screws (not

supplied).

5. Obtain 14505159-001 Tamper Switch per job

requirements. Installation of Tamper Switch is optional.

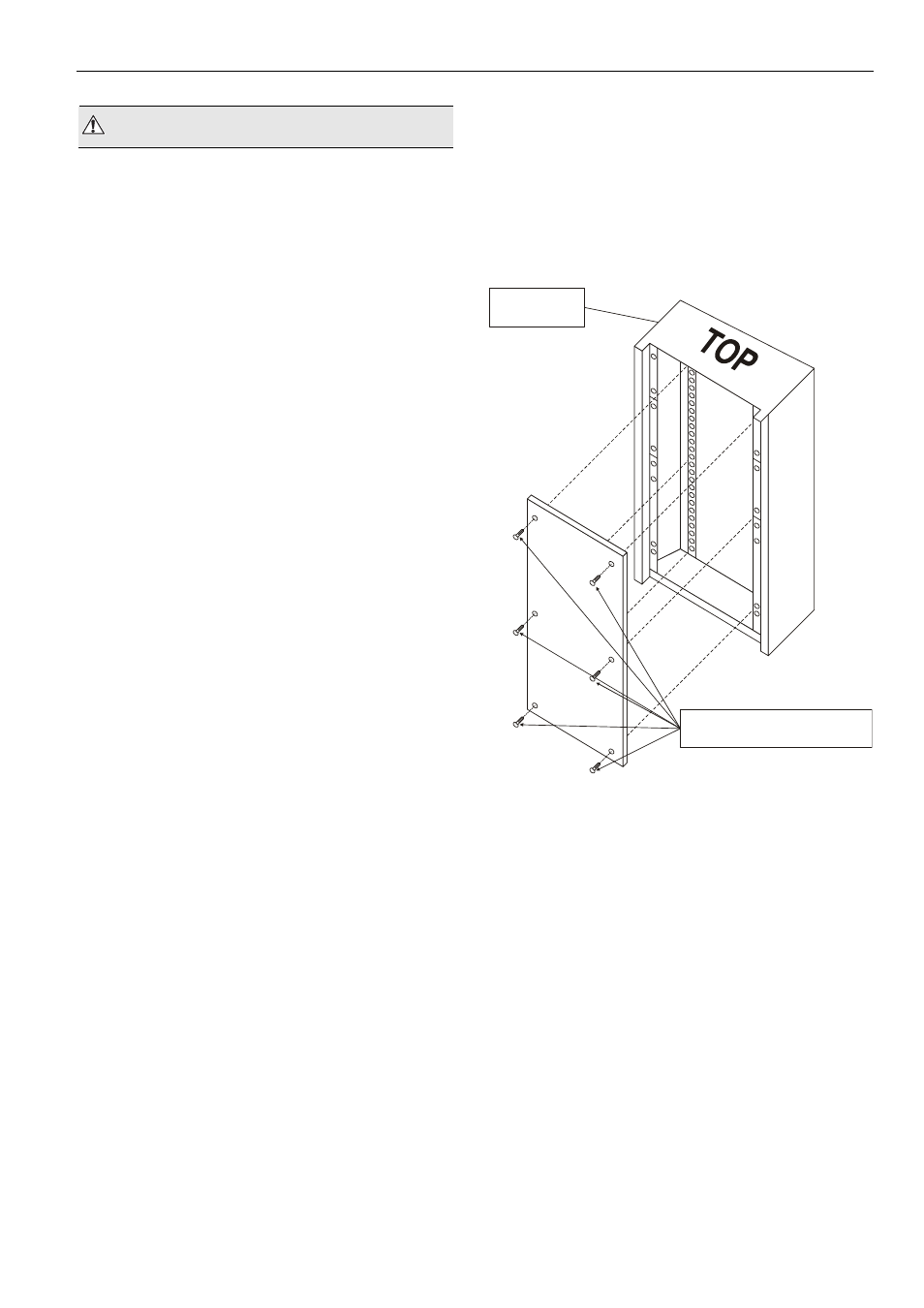

Installation

Mount controller subpanel in cabinet so all labeling is visible.

Secure full-size subpanel in place with six no. 10 x ½-inch

(13 mm) sheet metal screws (not supplied). Secure smaller

subpanel with four no. 10 x ½-inch (13 mm) sheet metal

screws (not supplied).

NOTE:

Subpanel must mount flat and should not bulge or

recess anywhere.

FULL-SIZE

CABINET

SIX NO. 10 x ½-INCH (13 mm)

SHEET METAL SCREWS

Fig. 1. Mounting controller subpanel in cabinet (full-size

subpanel cabinet shown)