Data file set-up, Panel reset, Typical power limited circuit for xl800 – Honeywell XL 800 SERIES User Manual

Page 11: Connecting single bus controller systems, Caution

Excel 800

Description of the XCL8010AU Controller Module

11

EN1B-0410GE51

R0908A

4

Locate separate from and below all building exhaust

fans and upstream of any prevailing winds.

5

Exhaust to outside of building.

6

Locate airflow differential switch.

7

Locate UL-listed damper pressure / position indicator

per damper installation instructions.

8

Smoke control must be initiated by a listed fire alarm

control unit or in zone automatic alarm devices and not

devices located outside of the smoke control zone.

Interconnecting wiring must be within 20 ft. (6 meters)

and in conduit.

9

Refer to NFPA 92A.

10

Verify that the AC voltage source connected to the

inside of the main line voltage terminal block is from a

UL-1481 listed uninterruptible power supply. The main

line voltage terminal block maximum current draw is

0.5 A. For 220/240 VAC (60 Hz) applications, verify

that no potential between any conductor and the earth

ground exceeds 150 VAC.

11

All external L

ON

W

ORKS

bus field wiring must be limited

to 4000 ft. (1200 meters) and be terminated to

14506944-001 transient protector (35 V, 290 mA max.)

except C-Bus field wiring communicating at 1 MHZ,

which uses 14502412-014 transient protector (19 V,

500 mA).

12

Panel Bus wiring must be in the same enclosure or

less than 20 ft. to adjacent enclosure. No protection is

required.

Data File Set-Up

Generate the engineering data file for the XL800 Series

Controllers. This data file has a mix of hardware points for the

necessary inputs and outputs to control fans, dampers, and

other equipment. In addition to the inputs and outputs, a

custom control program is written to control the outputs per

the sequence. The XL800 controllers can reset the program

once the data from the operator interface indicates a normal

condition for the dedicated smoke control equipment. Wire

conditions must be programmed to provide annunciation of

trouble conditions.

Also required for a dedicated application for the XL800, is a

weekly time program to test control points, fans, and dampers

by exercising the equipment and verifying feedback

automatically during low building activity periods.

Panel Reset

When in Smoke Control Mode, panel reset is accomplished

by resetting the initiating panel contact circuit or by the

separate initiating/reset switch on the FSCS panel.

CAUTION

Risk of electric equipment damage!

►

Failure to use listed/approved replacement parts can

damage product, degrade operation and result in loss of

safety function.

►

This product must be installed and operated within its

environmental, mechanical, and electrical specifications as

contained in this document.

►

When servicing, use only listed/approved replacement

parts ordered directly from the manufacturer.

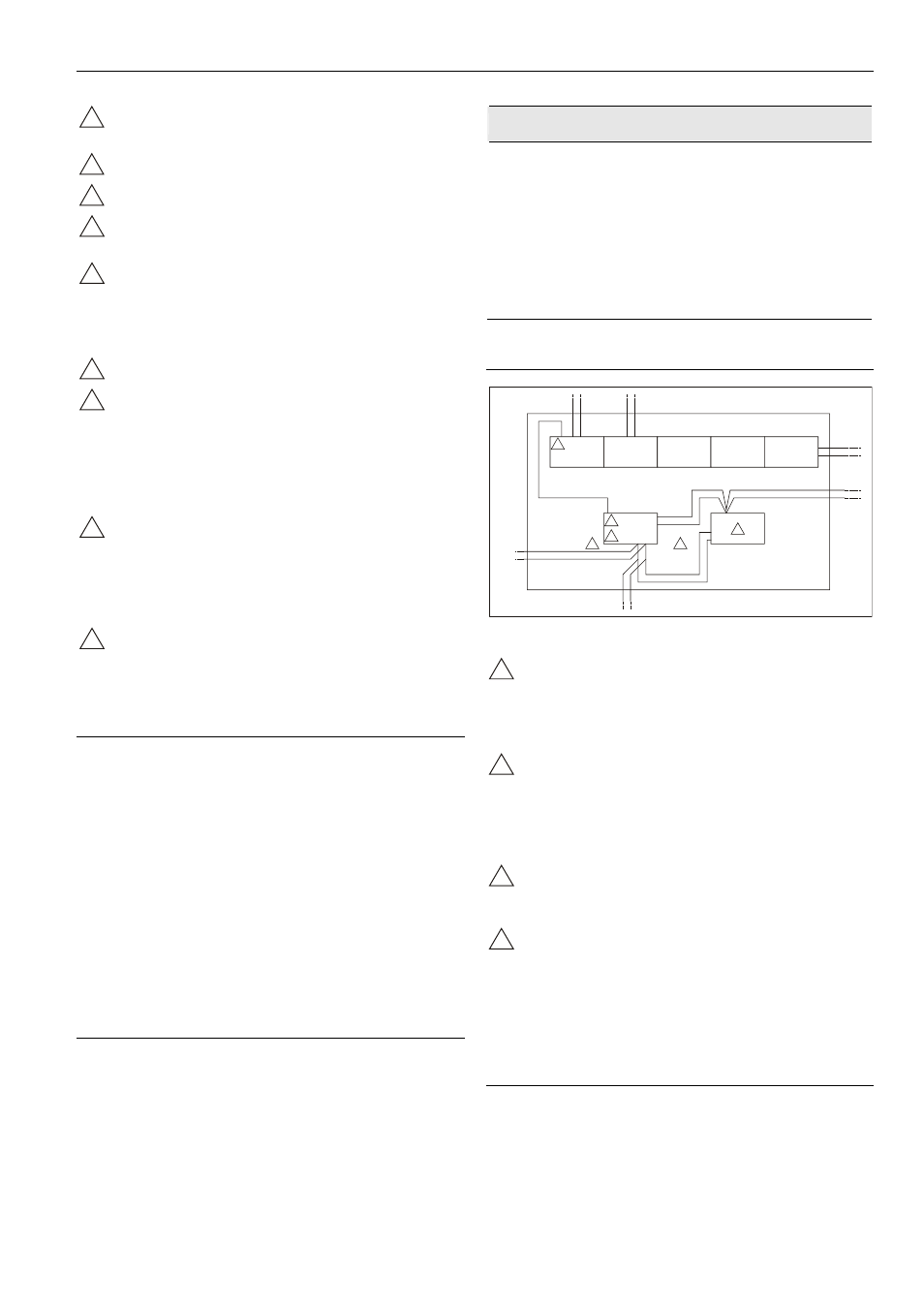

Typical Power Limited Circuit for XL800

ANALOG INPUT

MODULE

CPU

CONTROL

24VAC

ACCESSORY

24VAC

POWER LIMITED

24VAC

ANALOG OUTPUT

MODULE

DIGITAL INPUT

MODULE

DIGITAL OUTPUT

MODULE

2

2

2

3

1

1

POWER

LIMITED

POWER

LIMITED

NON-POWER

LIMITED

NON-POWER

LIMITED

NON-POWER

LIMITED

NON-POWER

LIMITED

Fig. 9. Typical power-limited circuit for XL800

1

14507287-001 through -003 power module accessory

24 VAC output (rated 2A) must be wired in accordance

with NFPA 70, Article 725 when routed within the

cabinet or adjacent cabinets and also for external field

wiring.

2

14507287-001, -002, -003, and -007 control power

module 24 VAC output is inherently power-limited.

Thus, all sourced power from the XL800 controller is

power-limited. All field wiring from these controllers

meet NFPA 70, Article 725 power limited Class II

requirements.

3

If a separate auxiliary power-limited 24 VAC power

source is required, use a control power module

(14507287-001 or -007 control supply).

4

Devices must be installed in areas as shown. All cable

must be routed as shown. All internal power-limited

wiring must be separated by ¼ inch (6 mm) or barrier

from non-power-limited wire. Excess wiring must be

cut, trimmed, and dressed properly to ensure that

proper clearances are maintained.

Connecting Single Bus Controller Systems

This section describes how to connect a controller system

which uses Panel Bus I/O modules, only or L

ON

W

ORKS

Bus

I/O modules, only.