Instruction manual – Emerson Process Management 1051 User Manual

Page 6

Instruction Manual

D100320X012

1051 and 1052 H & J Actuators

October 2012

6

Note

If the milled flats or the coupling on the end of the actuator output shaft (key 87) are oriented such that the output shaft cannot

accommodate the operated equipment shaft, refer to the Changing Positions portion of the Changing Actuator Mounting section.

This procedure describes how the output shaft can be repositioned to accommodate the operated equipment shaft.

3. If using an actuator with a J mounting adaptation, note that the valve shaft coupling (key 90) is furnished with two

keyways lettered A and B as shown in figure 8 and 12 (letters C and D on the coupling are not used and can be

disregarded). Align the appropriate keyway with the keyway in the operated equipment shaft. If using a Fisher

butterfly valve, align the appropriate keyway on the coupling with the valve shaft keyway indicated in table 9. Then

install the woodruff key (key 91) in the shaft keyseat, and slide the coupling onto the shaft. It is helpful to apply a

light coat of grease to the inside of the coupling before sliding it onto the shaft.

4. For an actuator with an H mounting adaptation, slide the actuator (with the user-provided mounting bracket

attached) into the user-provided coupling on the operated shaft. Then, secure the actuator to the operated

equipment in the desired mounting position with the appropriate fasteners, such as mounting cap screws. See

figures 4, 5 and 6 for output shaft dimensions.

5. For an actuator with a J mounting adaptation, secure the mounting bracket (key 22) to the valve body with the cap

screws (key 78, not shown). Tighten the cap screws to the bolt torques in table 4. For 31.8 and 38.1 mm (1-1/4 and

1-1/2 inch) valve shafts, also place the two spacers (key 92, not shown) between the mounting bracket and valve

body during this step.

6. For an actuator with a J mounting adaptation and a 50.8 mm (2-inch) output shaft (key 87, figure 14), note that the

valve shaft coupling (key 90, figure 14) is furnished with two keyways lettered A and B as shown in figure 8 (letters C

and D on the coupling are not used and can be disregarded). Align the appropriate keyway with the keyway in the

operated equipment shaft. Then, install the woodruff key (key 91, not shown in figure 14) in the shaft keyseat, and

slide the coupling onto the shaft using the appropriate coupling keyway (see table 9 and figure 8). It is helpful to

apply a light coat of grease to the inside of the coupling before sliding it onto the shaft. Secure the actuator

(user-provided mounting bracket) to the operated equipment in the desired mounting position with the

appropriate fasteners, such as mounting cap screws.

7. Follow the instructions given in the Turnbuckle Adjustment section before proceeding to the Loading Connection

portion of this section.

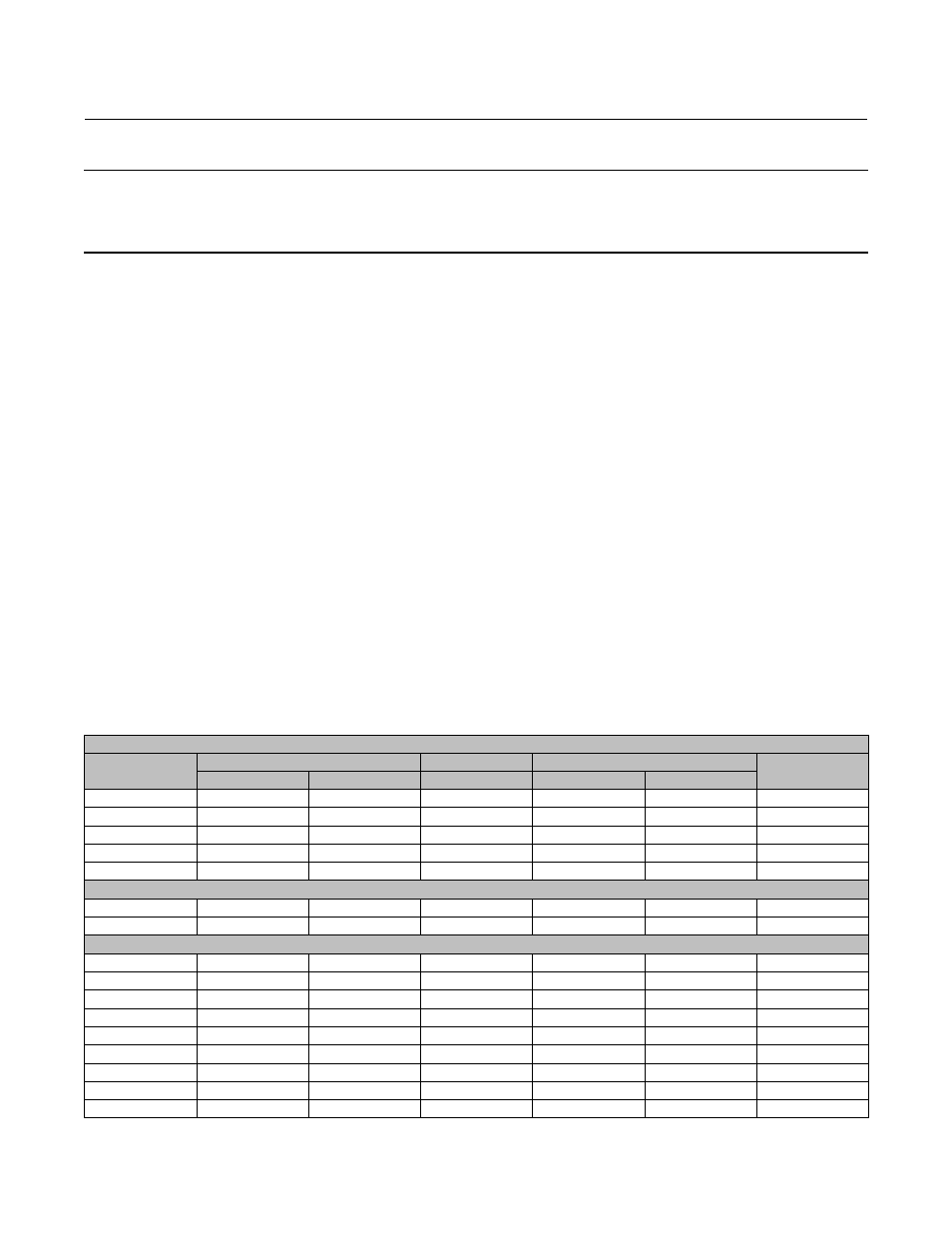

Table 4. Key 78 Cap Screw Torque Values

STYLE H MOUNTING

Actuator Size

Valve Shaft Diameter

Bolt Size

Bolt Torque

Key 78

Part Number

mm

Inch

Inch

N•m

lbf•ft

40

22.2

7/8

5/16

22.6

16.7

1C5958X0042

40

28.6

1-1/8

3/8

39

29

1A353124052

60

28.6

1-1/8

3/8

39

29

1A353124052

40

38.1

1-1/2

1/2

92

68

1A582324052

60, 70

38.1

1-1/2

1/2

92

68

1A582324052

STYLE J MOUNTING - FLAT PLATE MOUNTING

60, 70

44.5

1-3/4

1/2

92

68

1A582324052

60, 70

50.8

2

1/2

92

68

1A582324052

STYLE J MOUNTING - FISHER 7600, 9100, 9500 WITH KEYED SHAFT

40

9.5

3/8

3/8

39

29

1A341824052

40

12.7

1/2

3/8

39

29

1A341824052

40

15.9

5/8

3/8

39

29

1A341824052

40

19.1

3/4

3/8

39

29

1A341824052

60

19.1

3/4

3/8

39

29

1A341824052

40

25.4

1

3/8

39

29

1A341824052

60

25.4

1

3/8

39

29

1A341824052

60, 70

31.8

1-1/4

5/8

163

120

1P1477X0012

60, 70

38.1

1-1/2

5/8

163

120

1P1477X0012