Description, Instruction manual – Emerson Process Management 1051 User Manual

Page 2

Instruction Manual

D100320X012

1051 and 1052 H & J Actuators

October 2012

2

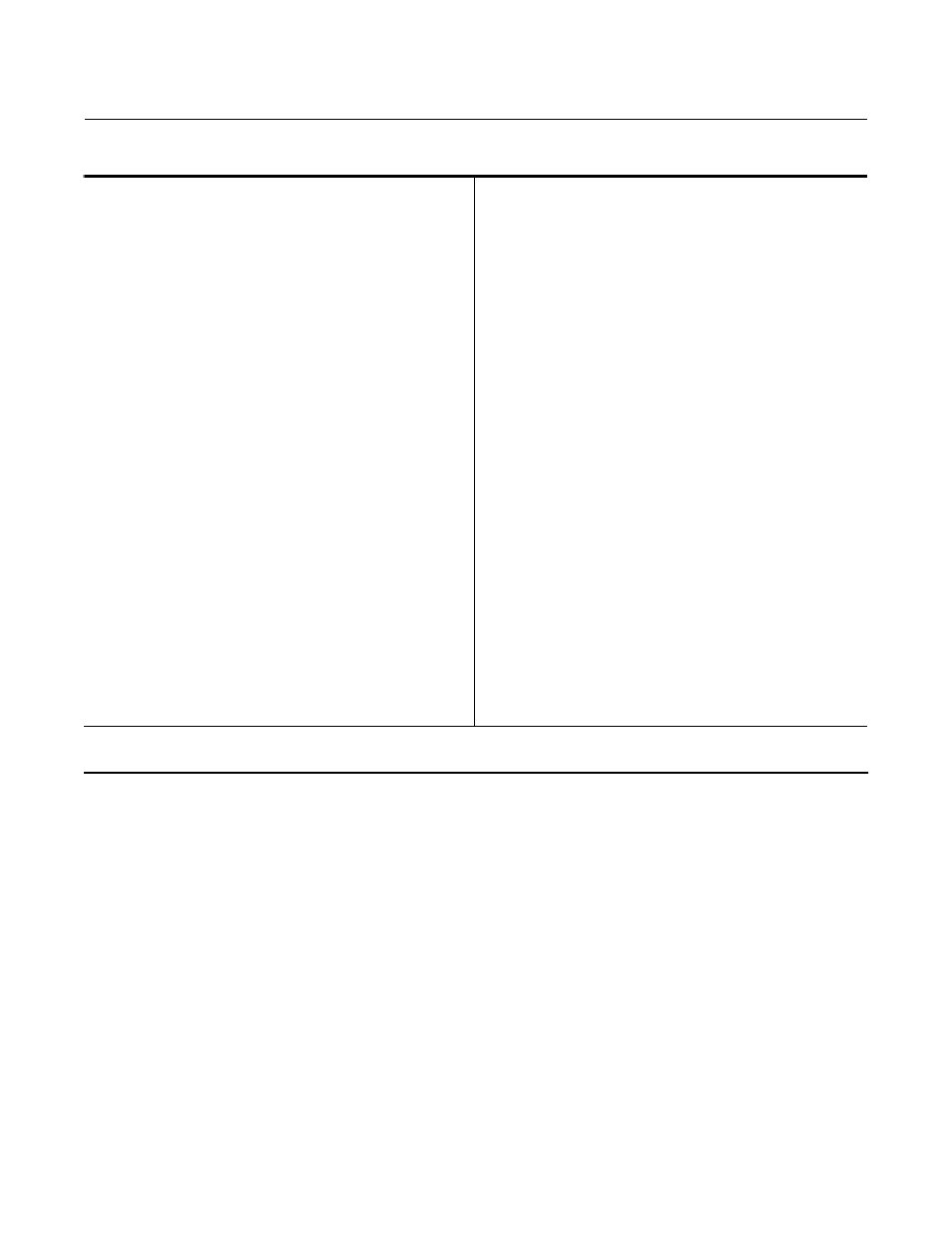

Table 1. Fisher 1051 and 1052 Actuator Specifications

Operation

Direct Acting: Increasing loading pressure extends

the diaphragm rod out of the spring barrel

Service:

1051: For on-off or throttling service with positioner

1052: For on-off or throttling service with or without a

positioner

Actuator Sizes

1051: 40, and 60

1052: 40, 60, and 70

Maximum Diaphragm Sizing Pressure

(2)(3)

Size 40: 4.5 bar (65 psig)

Size 60: 2.8 bar (40 psig)

Size 70: 3.8 bar (55 psig)

Maximum Diaphragm Casing Pressure

(2)(3)

Size 40: 5.2 bar (75 psig)

Size 60: 3.4 bar (50 psig)

Size 70: 4.5 bar (65 psig)

Maximum Valve Shaft Rotation

90, 75, or 60 deg with optional stops

Torque Limits (mm)

(4)

Limited by maximum diaphragm sizing pressure or

tables 2 and 3, whichever is less

Stroking Time

Dependent on actuator size, rotation, spring rate,

initial spring compression, and supply pressure. If

stroking time is critical, consult your Emerson Process

Management sales office

Material Temperature Capabilities

(3)

Nitrile Diaphragm or O-Rings

(1)

: -40 to 82_C

(-40 to 180_F)

Silicone Diaphragm: -40 to 149_C (-40 to 300_F)

Travel Indication

Graduated disc and pointer combination located on

actuator end of valve shaft

Pressure Connections

1/4 NPT internal

Mounting Positions

See figure 10

Approximate Weights

See table 8

Additional Specifications

For casing pressure ranges and for material

identification of the parts, see the Parts List

1. Nitrile O-rings are used in optional top-mounted handwheel, adjustable down travel stop, and adjustable up travel stop assemblies.

2. Use this value to determine the maximum torque output allowed.

3. The pressure / temperature limits in this manual and any applicable standard or code limitation for valve should not be exceeded.

4. Exceeding any torque requirements could damage the actuator and impair safe operation.

Do not install, operate, or maintain a 1051 or 1052 actuator without being fully trained and qualified in valve, actuator,

and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important

to carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If

you have any questions about these instructions, contact your Emerson Process Management sales office before

proceeding.

Description

1051 and 1052 diaphragm rotary actuators are pneumatic spring-return actuators for use with rotary-control valves

and other equipment. The 1051 actuator can be used for on-off service, or it can be used for throttling service when

equipped with a valve positioner. The 1052 actuator can be used for on-off service, or it can be used for throttling

service when equipped with or without a valve positioner. The 1052 actuator spring is adjustable.

The H mounting adaptation permits the actuator to be used with equipment other than Fisher valve bodies. The

mounting brackets and couplings for rotary actuation are user-provided. This mounting adaptation includes a

flat-surface mounting plate that is drilled and tapped for attaching the user-provided bracket. Cap screws for attaching

the bracket are provided. H mounting also includes an output shaft (with milled flats) to provide the Double D rotary

output either directly or through a user-provided coupling. Output shaft diameters and torque limits are listed in table

2. Dimensional information for the mounting plate and output shaft are shown in figures 4, 5, and 6.