Loading connection, Instruction manual – Emerson Process Management 1051 User Manual

Page 12

Instruction Manual

D100320X012

1051 and 1052 H & J Actuators

October 2012

12

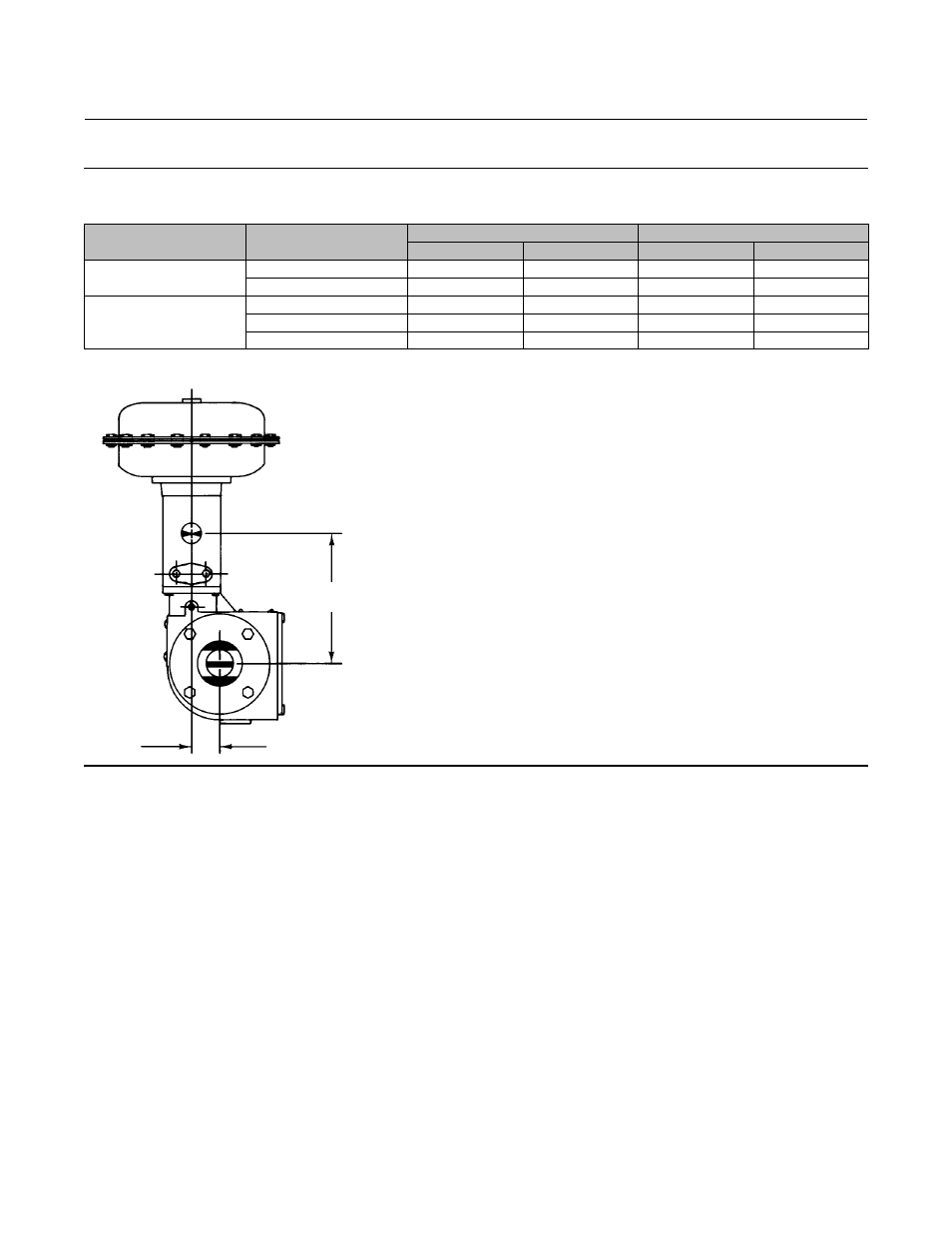

Figure 9. Center of Gravity Dimensions

ACTUATOR TYPE

ACTUATOR SIZE

X

Y

mm

Inch

mm

Inch

1051

40

15

0.6

191

7.5

60

10

0.4

361

14.2

1052

40

15

0.6

241

9.5

60

10

0.4

432

17.0

70

23

0.9

488

19.2

Y

X

19A1459-B

A3255

Loading Connection

1. Connect the loading pressure piping to the pressure connection in the top of the diaphragm casing.

For size 40 through 60 actuators, run either NPS 1/4 pipe or 3/8-inch tubing between the NPT 1/4 pressure connection

and the positioner or automatic controller.

For size 70 actuators, run either pipe or tubing between the pressure connection and the positioner or automatic

controller. If necessary, remove the 1/4-inch bushing in the pressure connection to increase connection size.

2. Keep the length of pipe or tubing as short as possible to avoid transmission lag in the control signal. If an accessory

(such as a volume booster or a positioner) is used, be sure that the accessory is properly connected to the actuator.

If a positioner is part of the assembly, the pressure connection to the actuator will normally be made at the factory.

3. When the actuator is completely installed and connected to the instrument, check for correct action (air-to-open or

air-to-close) to match the controlling instrument. For successful operation, the actuator stem and operating shaft

must move freely in response to the loading pressure change on the diaphragm.