Adjustment, Instruction manual, Warning – Emerson Process Management 1051 User Manual

Page 13

Instruction Manual

D100320X012

1051 and 1052 H & J Actuators

October 2012

13

Adjustment

WARNING

Before performing any adjustment steps, follow the steps in the WARNING at the beginning of the Maintenance section.

1051 and 1052 Turnbuckle Adjustment

Correct turnbuckle adjustment ensures that the valve body or other operated equipment is correctly closed when the

actuator is against its travel stops. The turnbuckle adjustment is the only adjustment necessary on the 1051 actuator.

Key numbers used in this procedure are shown in figure 12 for 1051 actuators and in figure 13 for 1052 actuators.

For accurate adjustment, remove the valve body or other operated equipment from the pipeline.

A regulated air supply will be required to stroke the actuator. Consult table 10 for the sizes of the three open end

wrenches required for this procedure.

1. Remove the access plate (key 59). Also remove the machine screws (key 60), if present.

Note

For the most accurate adjustment of the actuator, do not remove the cover (key 33) during this procedure.

2. Loosen the lower locknut (key 16).

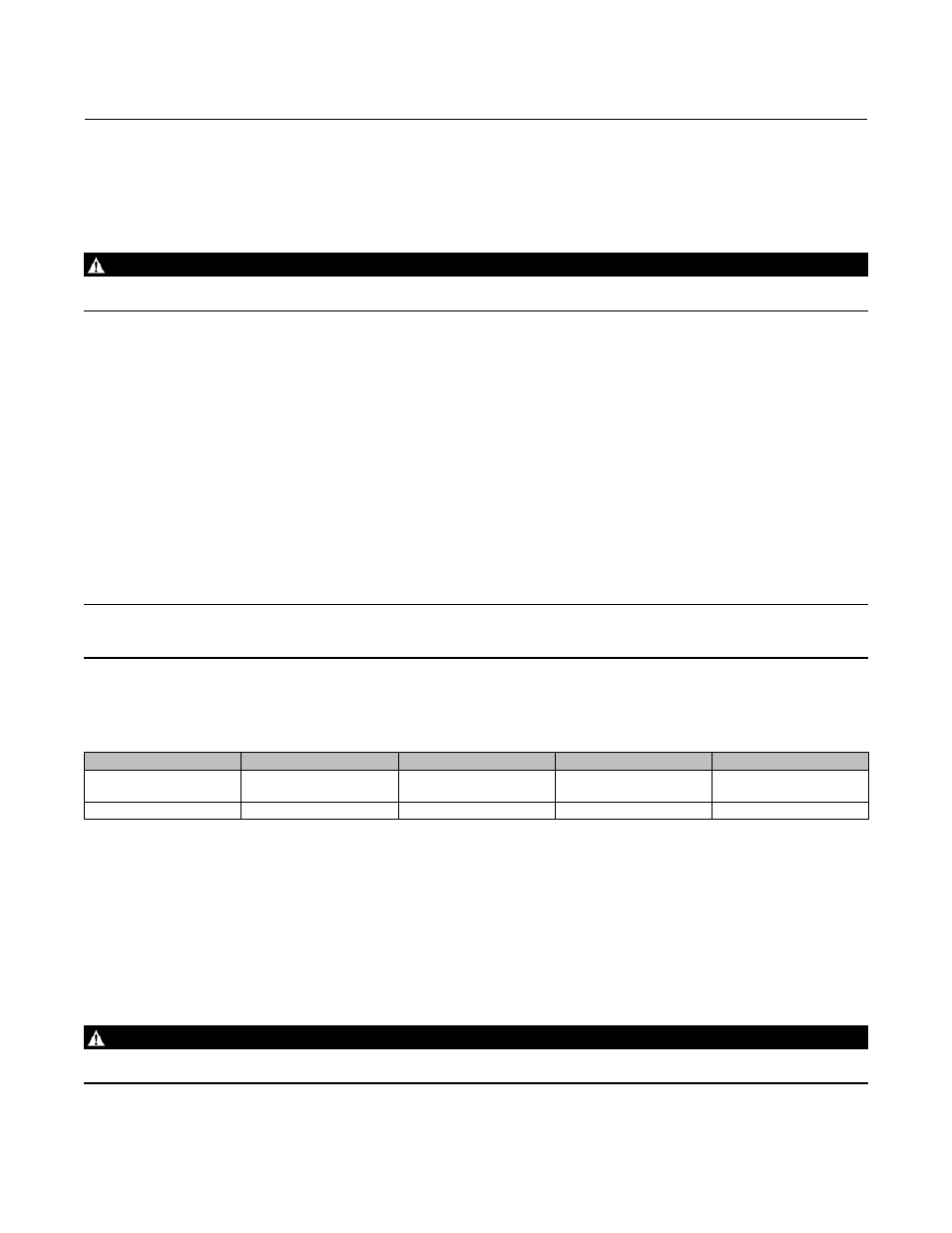

Table 10. Wrench Sizes Required for Turnbuckle Adjustment, Inches

Actuator

Size

Turnbuckle (Key 57)

Lower Locknut (Key 16)

Upper Locknut (Key 58)

1051 & 1052

40

60

1-1/8

1-5/16

3/4

15/16

1-1/8

1-5/16

1052

70

1-5/16

1-1/8

1-5/16

3. Make sure the actuator housing (key 20) is clear of any tools or other instruments that could obstruct the actuator

stroke path. Pressure the diaphragm casing enough to stroke the actuator down so that the left-hand threaded

upper locknut (key 58) is accessible through the access opening. Loosen the locknut.

4. Use one of the following:

a. For push-down-to-close action–Slowly stroke the actuator to the down travel stop. Consult the appropriate

instruction manual for determining the closed position of the valve body or other operated equipment. Adjust

the turnbuckle (key 57) until the closed position is reached. Lock this adjustment with the left-hand threaded

locknut (key 58). Stroke the actuator to the mid-travel position, and tighten the locknut (key 16). Tighten each

locknut to the appropriate torque value listed in table 11.

WARNING

Exceeding any torque requirements could damage the actuator and impair safe operation.