Actuator mounting, Instruction manual, Warning – Emerson Process Management 1051 User Manual

Page 5

Instruction Manual

D100320X012

1051 and 1052 H & J Actuators

October 2012

5

WARNING

To avoid personal injury or parts damage, do not use an operating pressure that exceeds the Maximum Diaphragm Casing

Pressure (table 1) or produces a torque greater than the Maximum Allowable Valve Shaft Torque (see Catalog 14). Use

pressure-limiting or pressure-relieving devices to prevent the diaphragm casing pressure from exceeding its limit.

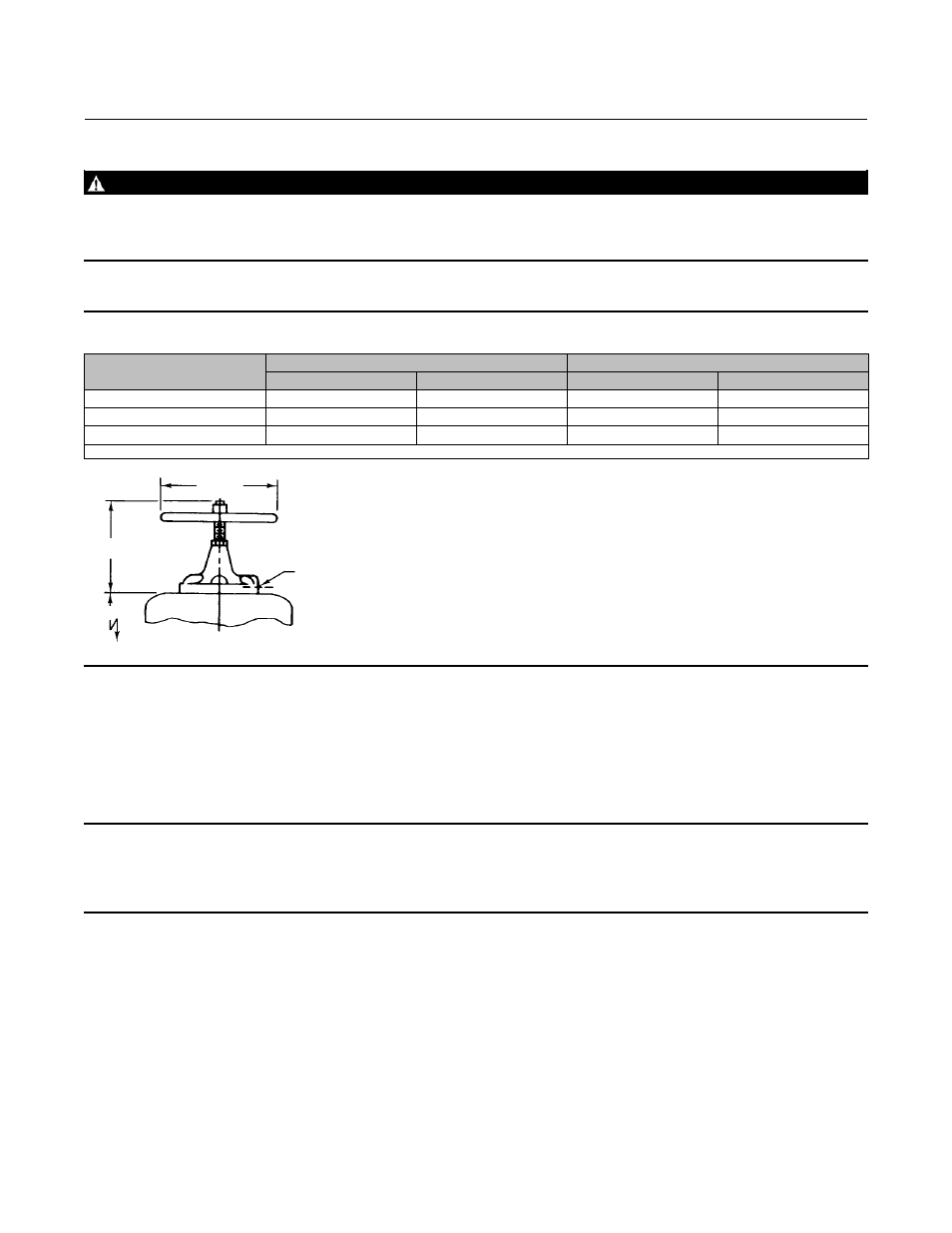

Figure 3. Top Mounted Handwheel

ACTUATOR SIZE

H

C

J

C

mm

Inch

mm

Inch

40

281

11.06

356

14.00

60

359

14.12

432

17.00

70

(1)

335

13.62

356

14.00

1. Size 70 available in 1052 only.

TOP-MOUNTED HANDWHEEL

19A1465-B

1/4 NPT

H

C

J

C

(DIA)

E

Actuator Mounting

Use the following steps to connect the actuator to a valve body or other equipment. Unless otherwise specified, key

numbers are shown in figures 12 and 13. Mounting dimensions are shown in figures 4, 5, 6, and 7.

Note

For an actuator with an H mounting adaptation and a 22.2 through 38.1 mm (7/8 through 1-1/2 inch) output shaft, find

dimensions and center of gravity information in figures 3, 4, 5, 6, and 9, and approximate weights in table 8. This information is

required for proper fabrication of the user-provided bracket and coupling.

1. For an actuator with an H mounting adaptation, attach an appropriate mounting bracket (not provided) to the

mounting plate (key 22) with the cap screws (key 78). See figures 4, 5, and 6 for mounting dimensions on the

mounting plate. Tighten the cap screws to the bolt torques listed in table 4.

2. Consult figure 10 for available mounting styles and positions. The actuator is normally positioned vertically with the

valve body or other equipment in a horizontal pipeline.