Maintenance, Stroking range, Instruction manual – Emerson Process Management 1051 User Manual

Page 15: Warning

Instruction Manual

D100320X012

1051 and 1052 H & J Actuators

October 2012

15

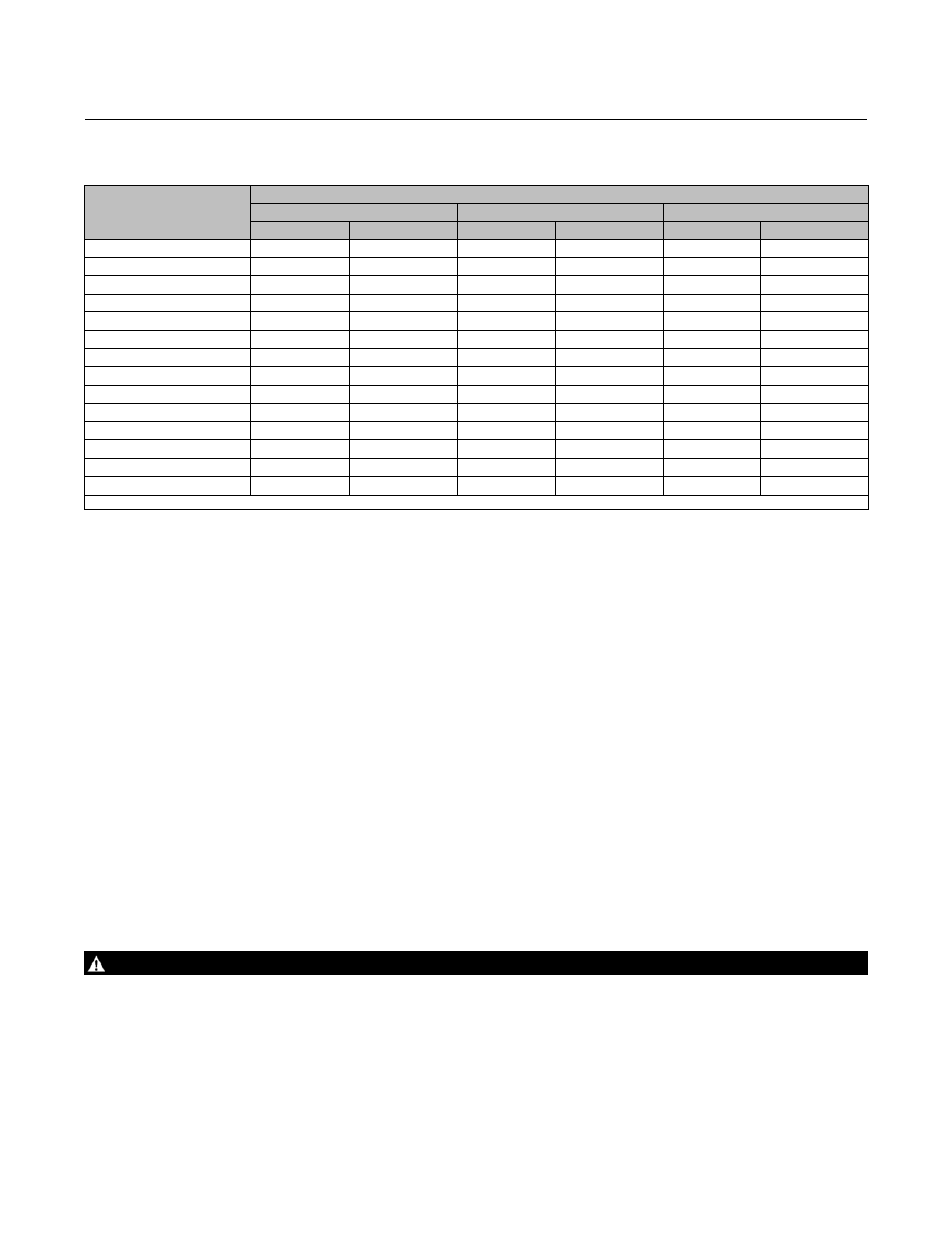

Table 11. Recommended Bolting Torques

(1)

KEY NUMBER

ACTUATOR SIZE

40

60

70

NDm

lbfDft

NDm

lbfDft

NDm

lbfDft

6

27

20

27

20

27

20

7 & 8

41

30

41

30

102

75

9

34

25

102

75

102

75

16

34

25

61

45

102

75

18

81

60

163

120

271

200

21

23

17

68

50

68

50

23

34

25

81

60

81

60

28

81

60

163

120

271

200

34

34

25

81

60

81

60

40

9

7

9

7

9

7

54 handwheel

34

25

34

25

34

25

54 down stop

27

20

66

49

69

51

58

102

75

163

120

163

120

141

41

30

41

30

81

60

1. Exceeding any torque requirements could damage the actuator and impair safe operation.

Stroking Range

The initial spring set listed on the nameplate has been determined to be the optimum setting, and it is not

recommended to make spring adjustments that will cause this value to change or be exceeded. For

push-down-to-open (PDTO) action, the initial spring set is normally the maximum allowable to provide the maximum

spring closing force. Any increase of this setting could over-stress the spring at full travel. For push-down-to-close

(PDTC) action, the initial spring set has been determined to be the optimum balance between the air to close and the

spring to open breakout torque.

If the 1052 actuator is to be changed from one action to another (i.e., from PDTC to PDTO), first refer to the initial

spring compression values listed in the table for keys 11 and 13 in the Parts List section. Then adjust the unit according

to the procedures in the Initial Compression portion of this section.

Maintenance

Actuator parts are subject to normal wear and must be inspected and replaced as necessary. The frequency of

inspection and replacement depends upon the severity of service conditions. Instructions are given below for

disassembly and assembly of parts. Key numbers referenced in the following steps are shown in figure 12 for 1051

actuators and in figure 13 for 1052 actuators unless otherwise specified.

WARNING

Avoid personal injury or property damage from sudden release of process pressure or uncontrolled movement of parts.

Before performing any maintenance operations:

D

Do not remove the actuator from the valve while the valve is still pressurized.

D

Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D

Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.