Ella Moss Automobile Parts User Manual

Page 15

M:\Product Information\366-348\Instructions\366-348 MGB Fuel Injection Installation Instructions_Grant_2.doc

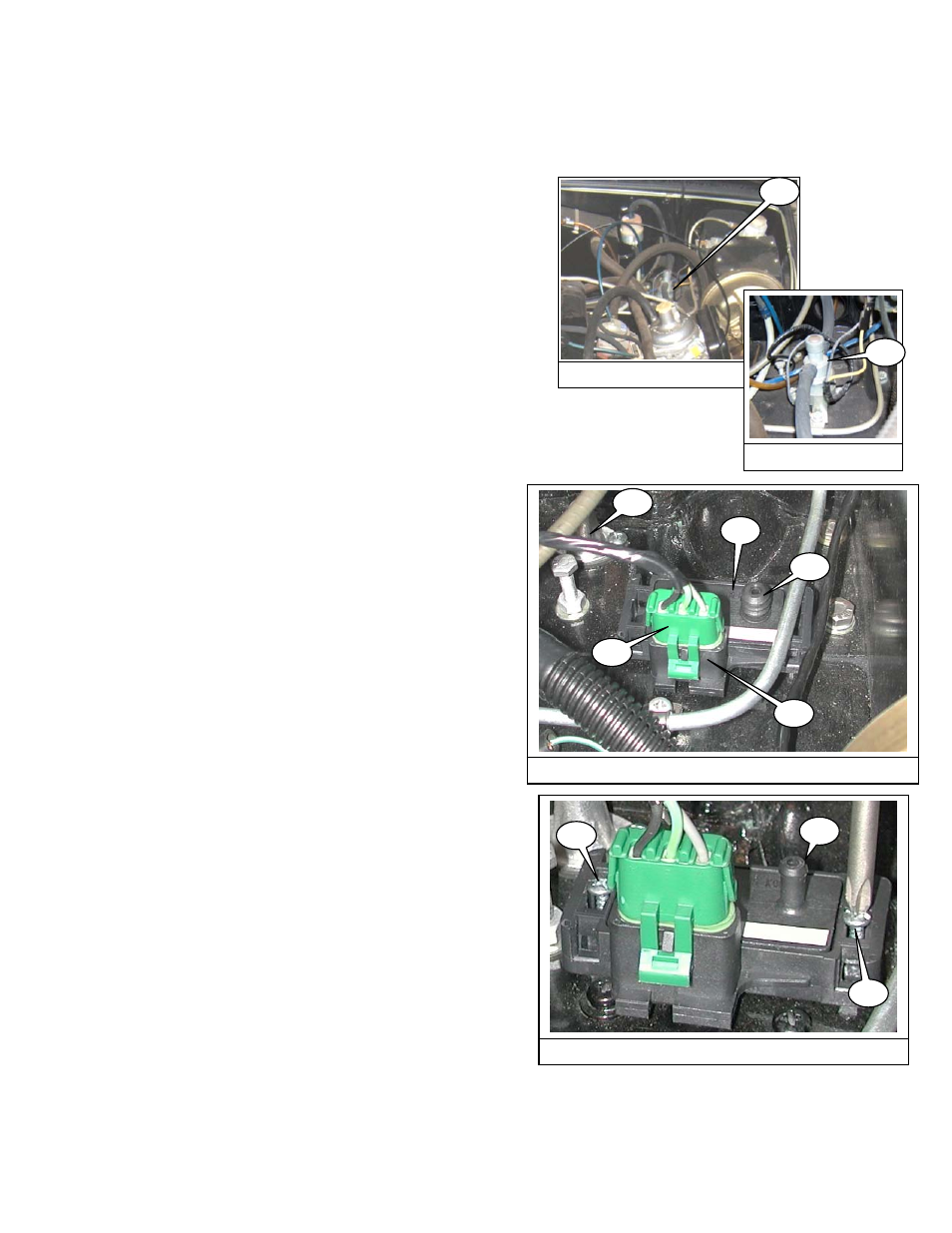

Installation Part 7 – Installing the Manifold Absolute Pressure (MAP) Sensor

The MAP sensor is a variable resistor used to monitor the

difference between the pressure inside the intake manifold

and normal atmospheric pressure outside the manifold.

This information is used by the electronic Control Unit

(ECU) to determine engine load. When the engine is under

load, the computer will alter the fuel mixture to improve

performance and reduce emissions. Before we get started

we need to make a place for the MAP sensor. Some late

MGBs came equipped with a mechanical fuel cut-off valve

that sits on the firewall shelf near the pedal box and fuel

filter. The valve (27.1, 27.2) is connected to the fuel hose

between the fuel filter and the carb. These valves are

prone to failure, and most of them have already been

removed. If you have one, we suggest thay you remove it

366-348 Inst Fig 27B

27.2

366-348 Inst Fig 27A

27.1

along with the 2 pieces of hose attached to the valve.

77. Locate separate bag that contians the Manifold

Absolute Pressure (MAP) sensor. It is a small black

plastic box (27.3) with a nipple for a vacuum hose

(27.4) and a socket for a wiring connector (27.5).

366-348 Inst Fig 27C

27.3

27.5

27.4

27.7

27.6

78. Connect the harness plug (27.6) and position the MAP

sensor so there is slack in the wires. It fits nicely on

the firewall shelf near where the throttle cable guide is

mounted (27.7).

79. There are two slots for screws at either end of the

plastic box; the screws can be positioned anywhere in

those slots. Mark the position of one of the screws.

80. Remove the MAP sensor and look under the dash in

the cockpit- make sure there are no wires in the area-

you are about to drill a couple of holes.

81. Center punch your mark and drill one hole using a

3/32” drill bit.

366-348 Inst Fig 28

28.1

28.3

28.2

82. Find the two #6 x 1 ¼” sheet metal screws and the two

#6 flat washers provided in the kit. Secure the MAP

sensor to the firewall shelf using one screw and

washer (28.1).

83. Using the MAP sensor as a guide, drill a second hole

using a 3/32” drill bit and install the second screw and

flat washer. (28.1) Do not over-tighten. The flat

washers were not used in the installation

photographed- that’s when we decided they were

needed.

84. Pull the rubber bellows/cover (see 27.2 on previous

page) off the vacuum nipple, exposing the plastic hose

barb (28.3).

This completes part 7 of the installation.

Page 15 of 52